FTL vs LTL Shipping: How to Choose the Right Option

Are you trying to figure out if your shipment needs its own trailer or if you should share the ride? Making the right call on FTL vs LTL shipping can be the difference between a healthy profit margin and an expensive logistical headache. Most shippers find themselves at this crossroads once their volume grows beyond standard parcel services. You have probably seen the acronyms used interchangeably, but the operational differences are massive. We are here to help you navigate those details so you can choose the most efficient path for your freight.

The short version is that your choice depends on three main things: weight, volume, and urgency. While general guides cover the basics, you need the specific details that actually help you save money and protect your cargo. For a complete overview of the broader logistics landscape, check out our main guide on freight shipping methods compared. In this focused breakdown, we are going to get straight into what works, what does not, and exactly what you should do for your specific shipment. Let us get into the details.

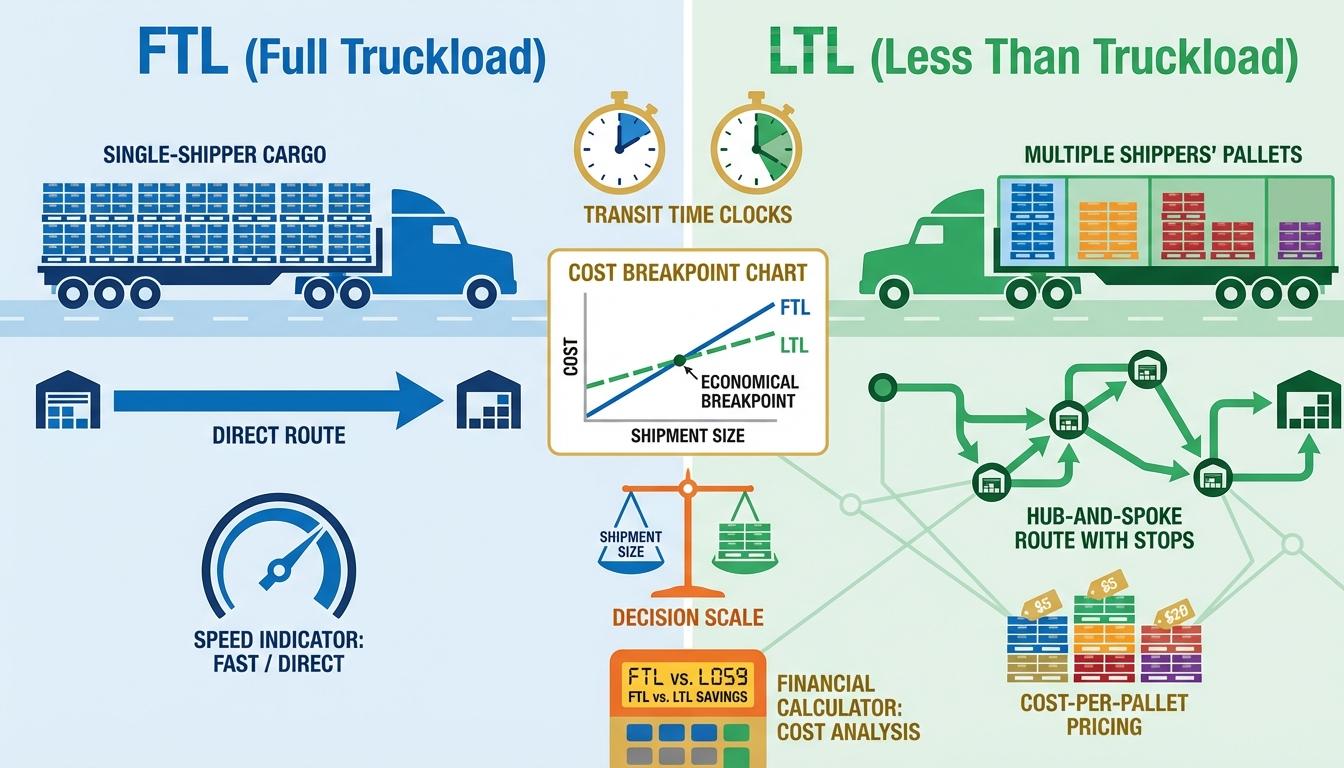

What is the Real Difference Between FTL and LTL Shipping?

When it comes to FTL vs LTL shipping, the key difference is how much of the truck you are paying for. Full Truckload (FTL) means you have booked the entire 53 foot semi trailer for your goods alone. You own the space from the moment it leaves your dock until it arrives at the destination. We typically see FTL used for shipments that take up more than 12 to 14 linear feet of trailer space or weigh more than 15,000 pounds. It is a direct route, meaning the driver picks up your load and heads straight to the receiver.

Less Than Truckload (LTL) works more like a bus system for freight. Your pallets share space with cargo from other companies. This is the go-to choice for shipments between 150 and 15,000 pounds that do not require a full 53 foot trailer. Instead of a direct route, LTL shipments move through a hub and spoke network of terminals. Here is what that actually looks like. Your freight might be loaded and unloaded several times as it moves from one truck to another at various regional hubs. This sharing of space is what makes LTL so cost effective for smaller loads.

The practical takeaway is simple. If you have 24 to 30 standard pallets, you are firmly in FTL territory. If you are shipping 1 to 6 pallets, LTL is almost always your best move. The gray area exists in the middle, and that is where the details matter most for your budget. Your next step is to count your pallets and get an accurate weight before requesting any quotes.

When to Choose Less Than Truckload (LTL)

LTL is the backbone of shipping for small to medium businesses. It allows you to move palletized freight without the massive expense of a dedicated truck. But cost is not the only factor here. You should choose LTL when your timeline is flexible. Because the truck makes multiple stops to pick up and drop off other shippers cargo, transit times are often estimated rather than guaranteed. If you have a few days of wiggle room, the savings are usually worth the extra time.

Specific equipment needs often drive shippers toward LTL as well. If your pickup or delivery location does not have a loading dock, you will need a liftgate. Most LTL carriers offer liftgate services as an add on for a small fee. FTL carriers rarely have liftgates on 53 foot trailers, making LTL the only viable option for many residential or retail deliveries. This is a detail that changes everything if you are shipping to a storefront or a warehouse with limited infrastructure.

The Hub-and-Spoke Reality

You need to understand how the hub and spoke network affects your goods. In an LTL environment, your freight is handled at every terminal stop. Forklift operators will move your pallets on and off trailers multiple times. This means your packaging must be top notch. We recommend double wrapping your pallets and using heavy duty corner boards. If your product is extremely fragile or cannot be stacked, the shared environment of LTL might pose too much risk. According to the Federal Motor Carrier Safety Administration, proper cargo securement is vital, and in LTL, that responsibility often starts with how well you build your pallet.

Here is the step-by-step breakdown for LTL success:

- Accurately measure and weigh every pallet to avoid “re-weigh” fees.

- Identify if you need accessorials like liftgates or inside delivery.

- Ensure your freight is packaged to withstand multiple handlings.

- Allow for a 2 to 3 day window beyond the estimated delivery date.

When to Pull the Trigger on Full Truckload (FTL)

There comes a point where sharing a truck no longer makes sense. Full truckload shipping is the gold standard for speed, security, and volume. If you are shipping more than 12 pallets, you are likely reaching the price point where FTL becomes competitive. But beyond the pallet count, FTL is about control. When you book an FTL shipment, the driver stays with your load from point A to point B. There are no intermediate stops, no terminal transfers, and no other shippers cargo to worry about.

Time sensitive shipments almost always require FTL. If you have a strict “must arrive by” date for a retail giant or a manufacturing line, LTL is too risky. FTL provides a much more accurate delivery estimate because the variables are limited to traffic and weather. Furthermore, if you are moving high value or fragile goods, FTL is the safer bet. Since the trailer is sealed at your dock and only opened at the destination, the risk of theft or handling damage drops significantly.

Your best move here is to use FTL when:

- Your shipment weighs more than 15,000 pounds.

- You are shipping more than 10 to 12 pallets.

- The goods are high value or easily damaged.

- You have a firm deadline that cannot be missed.

For those moving specialized cargo across borders or via different modes, it is worth looking into how intermodal freight shipping benefits might complement your FTL strategy by combining truck and rail for better rates over long distances.

The Financial Breakdown: FTL vs LTL Freight Rates

Let us cut to what matters: the money. FTL freight rates are usually calculated per mile or as a flat spot rate for a specific lane. These rates fluctuate based on market capacity, fuel prices, and seasonal demand. You are paying for the whole truck, so the cost per pallet decreases as you fill the trailer. This creates economies of scale that high volume shippers rely on to keep their margins healthy.

LTL freight rates are a bit more complex. They are determined by freight class, weight, and the distance between zones. Freight class is a standardized system that looks at the “shipability” of your goods, including density, stowability, and liability. A pallet of ping pong balls will have a different class than a pallet of steel bolts. If you get the class wrong, the carrier will re-rate your shipment, and the bill will be much higher than your original quote. This is where most people get it wrong because they overthink the weight and ignore the density.

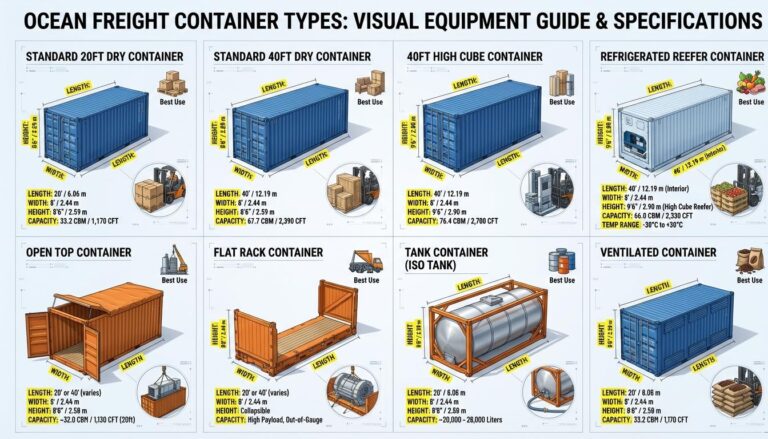

The real question is: where is the tipping point? Typically, if you are shipping 6 to 10 pallets, you should ask for both an LTL and an FTL quote. We have seen many cases where a “volume LTL” quote is actually more expensive than booking a dedicated cargo van or a small box truck. Always compare the total cost, including any fuel surcharges or residential delivery fees, to see which mode wins. If you are shipping internationally or using specialized containers, you might also want to consult a guide on ocean freight container types to see how your palletized cargo fits into larger global logistics chains.

Handling and Risk Management

One of the details that changes everything is the damage claim rate. In the shipping world, every time a piece of freight is moved, the chance of damage increases. LTL shipments are handled at least two to four times on average. Forklift blades, tight turns at terminals, and shifting loads from other shippers are all real threats. If your product cannot be easily repaired or replaced, the lower cost of LTL might be a false economy.

FTL offers a “shipper load and count” environment. You load the truck, you seal the trailer, and the receiver breaks the seal. This creates a clear chain of custody. If the seal is intact but the goods are damaged, it is likely a packaging issue. If the seal is broken, you have a clear case for a claim. This level of security is why pharmaceutical companies, electronics manufacturers, and high end furniture brands almost exclusively use FTL freight. Research from the Certified Logistics and Logistics Management resources suggests that reducing touchpoints is the single most effective way to lower insurance premiums and claim frequencies.

The practical takeaway is to assess your risk tolerance. If you are shipping sturdy industrial parts, LTL is fine. If you are shipping glass display cases, pay the premium for FTL. It will save you the headache of filing claims and disappointing your customers. For more context on how different transport modes handle risk, you can revisit our freight shipping methods compared guide.

Quick Reference: FTL vs LTL at a Glance

- Shipment Size: LTL is for 1 to 6 pallets; FTL is for 24 to 30 pallets.

- Weight Limits: LTL usually caps at 15,000 lbs; FTL goes up to 45,000 lbs.

- Transit Speed: FTL is direct and faster; LTL involves multiple stops and transfers.

- Cost Structure: LTL is per pound/class; FTL is per mile/lane.

- Risk Level: LTL has higher handling risk; FTL is low risk with exclusive use.

- Flexibility: LTL offers more options for liftgates and residential areas.

Common Questions About FTL vs LTL Shipping

What is the main difference between FTL and LTL shipping?

The answer is exclusivity and volume. FTL dedicates an entire 53 foot truck to your shipment alone, while LTL mixes your freight with other shippers to fill the trailer. This makes FTL faster and more secure, while LTL is more affordable for small loads.

When should I use LTL over FTL?

You should use LTL when your shipment is under 15,000 pounds or takes up less than 6 pallets. It is the best choice for non-urgent freight where saving money on transport is more important than a direct, high speed delivery.

Is FTL faster than LTL?

Yes, FTL is almost always faster. Since the driver goes directly from your origin to the destination without stopping at sorting terminals, you avoid the delays inherent in the hub and spoke system used by LTL carriers.

What shipment size makes FTL more cost-effective?

The tipping point is usually around 10 to 12 pallets or 15,000 pounds. At this volume, the cost of paying for the whole truck (FTL) often becomes cheaper per unit than paying the high weight-based rates of an LTL carrier.

Can LTL handle fragile items?

Yes, but it requires significantly better packaging. Because LTL freight is loaded and unloaded multiple times, you must use heavy duty pallets, shrink wrap, and padding to protect against the increased risk of damage during handling.

Now you have the specific answer you came for. The key point? Match your shipping mode to your specific load size and risk tolerance. If you are shipping a few pallets and have time to spare, LTL will save your budget. If you are moving a massive load or high value goods on a deadline, FTL is the only way to go.