Intermodal Freight Shipping: When and Why It Makes Sense

Are you wondering if intermodal freight shipping is actually worth the switch from traditional long-haul trucking? You are likely looking for a specific answer rather than a general overview of the logistics industry. While standard trucking remains the default for many businesses, there is a distinct threshold where shifting to rail becomes the smarter move for your budget and your timeline. We are going to get straight into what works, what does not, and exactly when you should consider this method for your cargo. Let us get specific.

You probably already know that intermodal involves moving goods in a single container using multiple modes of transport. However, the real value lies in the details of how those modes connect without anyone ever touching the freight inside. This is the detailed breakdown you have been searching for to help you decide if your current shipping strategy is leaving money on the table. To see how this fits into the bigger picture of logistics, you should check out our main guide on freight shipping methods compared. For now, let us focus strictly on the intermodal side of the house.

The Specific Mechanics of Intermodal Freight Shipping

When we talk about intermodal freight shipping, we are describing a system where cargo stays sealed in a standardized container from the point of origin to the final destination. The freight moves from a truck to a train, and perhaps to a ship, but the contents are never handled during these transitions. This is the key difference between intermodal and older methods where workers had to manually move boxes or crates between different vehicles. We call that old method break-bulk shipping, and it was notoriously slow and expensive.

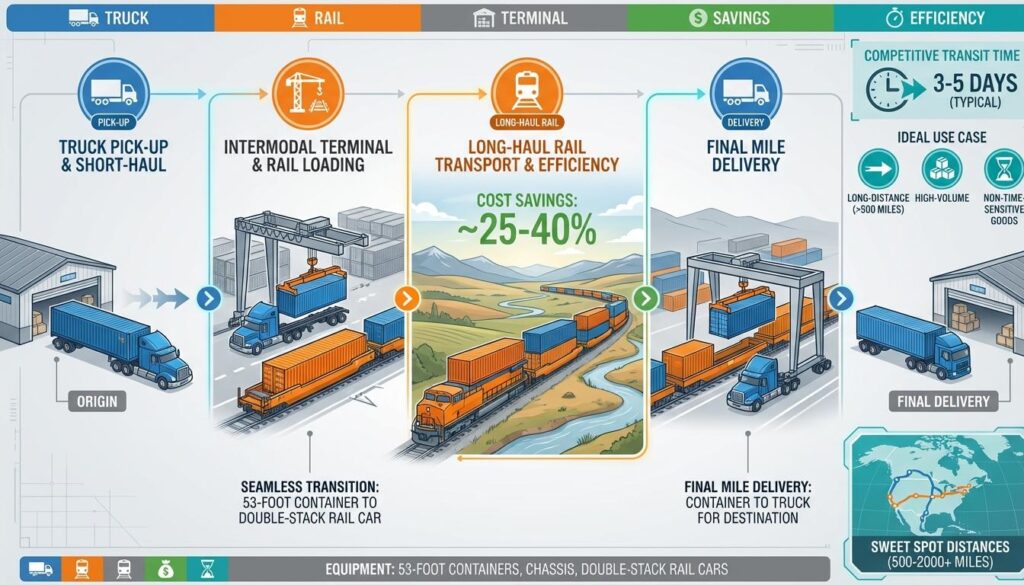

The process usually begins with intermodal drayage. This is a short-distance trucking service that picks up a container from your warehouse and brings it to a local rail terminal. Once there, a massive crane lifts the container and places it onto a specialized railcar. The train handles the long-haul portion of the journey, which is where the real efficiency happens. Finally, another drayage truck picks up the container at the destination rail hub and delivers it to the customer. Here is the thing most people miss. The container itself acts as the “warehouse” during the entire trip, protecting your goods from theft, weather, and damage during mode switches.

So what does this look like in practice? Imagine you are shipping a large volume of consumer goods from a factory in Ohio to a distribution center in California. Instead of paying for a single truck to drive 2,500 miles, you use a drayage truck for the first 50 miles, a train for the next 2,400 miles, and another truck for the final 50 miles. This combination utilizes the strengths of both modes. You get the door-to-door flexibility of a truck and the massive fuel efficiency of a locomotive. The practical takeaway is that you are no longer limited by the availability or cost of a single long-haul driver.

Why the History of the Container Matters to You

It is hard to appreciate how efficient modern intermodal container shipping is without looking at where it started. Before the 1950s, loading a ship or a train was a nightmare of manual labor. According to the Association of American Railroads, labor costs could account for up to 80 percent of the total cost of shipping a product. This changed when Malcolm McLean, a trucking magnate, realized that it was faster to move the entire truck trailer or container rather than the individual items inside. In 1956, he pioneered the use of standardized steel containers that could be moved seamlessly from a truck to a ship.

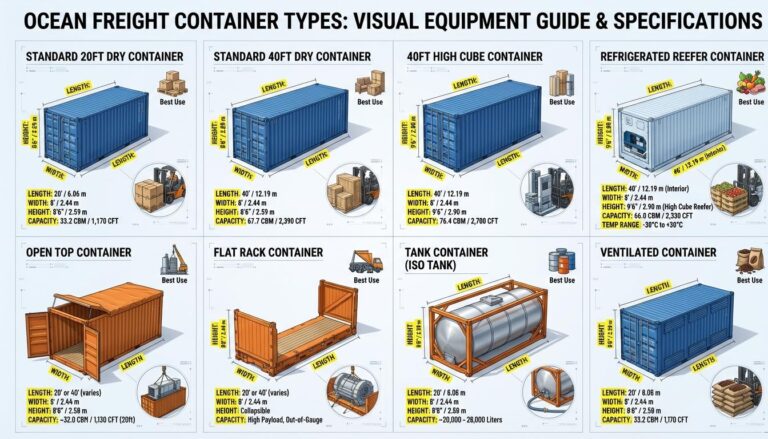

The standardization of these boxes is vital for your logistics planning today. In 1961, the International Organization for Standardization (ISO) set global dimensions for these containers. This meant that a box packed in Shanghai would fit perfectly on a truck in New Jersey and a train in Chicago. For more on the containers themselves, read our ocean freight container types guide. This global uniformity is what allows us to move millions of tons of freight with minimal delays. Without these standards, the modern global supply chain would simply ground to a halt under the weight of its own complexity.

Another massive leap forward occurred in 1977 with the introduction of double-stack railcars. These are specialized “well” cars that allow two containers to be stacked on top of each other. By lowering the center of gravity, railroads were able to double the amount of freight a single train could carry without increasing the train’s length. By 1984, this became the industry standard. For you, this means that rail intermodal can move the equivalent of 400 trucks on a single train. That is a level of scale that traditional trucking can never match.

When It Makes Financial Sense: The 15-20% Rule

Here is the specific answer you are likely looking for. When does intermodal actually save you money? In the logistics world, we generally look for the “sweet spot” where rail intermodal becomes cheaper than a standard truckload. For most shipments, that threshold is around 500 miles. If your freight is moving less than 500 miles, the costs of drayage and terminal handling usually outweigh the savings of the rail. However, once you cross that 500 to 700-mile mark, the savings start to stack up quickly.

Typically, intermodal freight shipping can save you between 15 and 20 percent compared to long-haul trucking. This happens because trains are incredibly fuel-efficient. A single gallon of diesel can move one ton of freight nearly 500 miles on the rails. Trucks simply cannot compete with that level of efficiency. When fuel prices spike, the cost gap between rail and road widens even further, making intermodal an excellent hedge against volatile energy markets. When evaluating the financial side, it helps to look at how FTL vs LTL shipping cost models differ from intermodal pricing to ensure you are choosing the right bucket for your budget.

Your best move here is to audit your current shipping lanes. Look for any routes that are consistently over 750 miles and have a high volume of recurring shipments. These are your prime candidates for a truck to rail conversion. While the transit time might be one or two days longer than a dedicated truck, the cost savings often justify the slight delay. If you have predictable lead times and a desire to cut operational costs, the rail is almost always the answer.

Key Factors Influencing Cost

- Distance: The longer the haul, the higher the potential for savings.

- Weight: Rail is much better at handling heavy loads that might trigger surcharges or “heavy haul” permits on the highway.

- Drayage Proximity: If your warehouse is within 50 miles of a major rail hub, like those operated by BNSF or Union Pacific, your costs will be significantly lower.

- Fuel Prices: As diesel prices go up, the relative savings of rail intermodal increase.

Intermodal Drayage: Solving the First and Last Mile

We often hear shippers worry that rail is too rigid because trains do not pull up to warehouse loading docks. This is where intermodal drayage comes in. Drayage is the specialized trucking service that bridges the gap between the rail terminal and the shipper or receiver. It is the connective tissue of the entire intermodal system. Without efficient drayage, the cost savings gained on the tracks would be eaten up by delays at the terminal.

When you use rail intermodal, you are essentially hiring three different “legs” of transport. Leg one is the drayage truck from your door to the terminal. Leg two is the train. Leg three is the drayage truck from the destination terminal to your customer. Managing these transitions requires precision. Terminal congestion is a real factor that can lead to drayage delays, especially during peak seasons. We recommend working with a provider who has deep relationships with local drayage fleets to ensure your containers do not sit idle on the tarmac.

The practical takeaway here is that you must factor drayage into your scheduling. You cannot treat an intermodal shipment exactly like a truckload shipment. You need to allow for “gate time” at the rail hub and potential wait times for chassis. A chassis is the specialized trailer frame that a container sits on while being pulled by a truck. If there is a chassis shortage at the terminal, your shipment will stall. This is one of those areas where getting it right makes a real difference in your overall supply chain reliability.

Sustainability and the “Green” Advantage

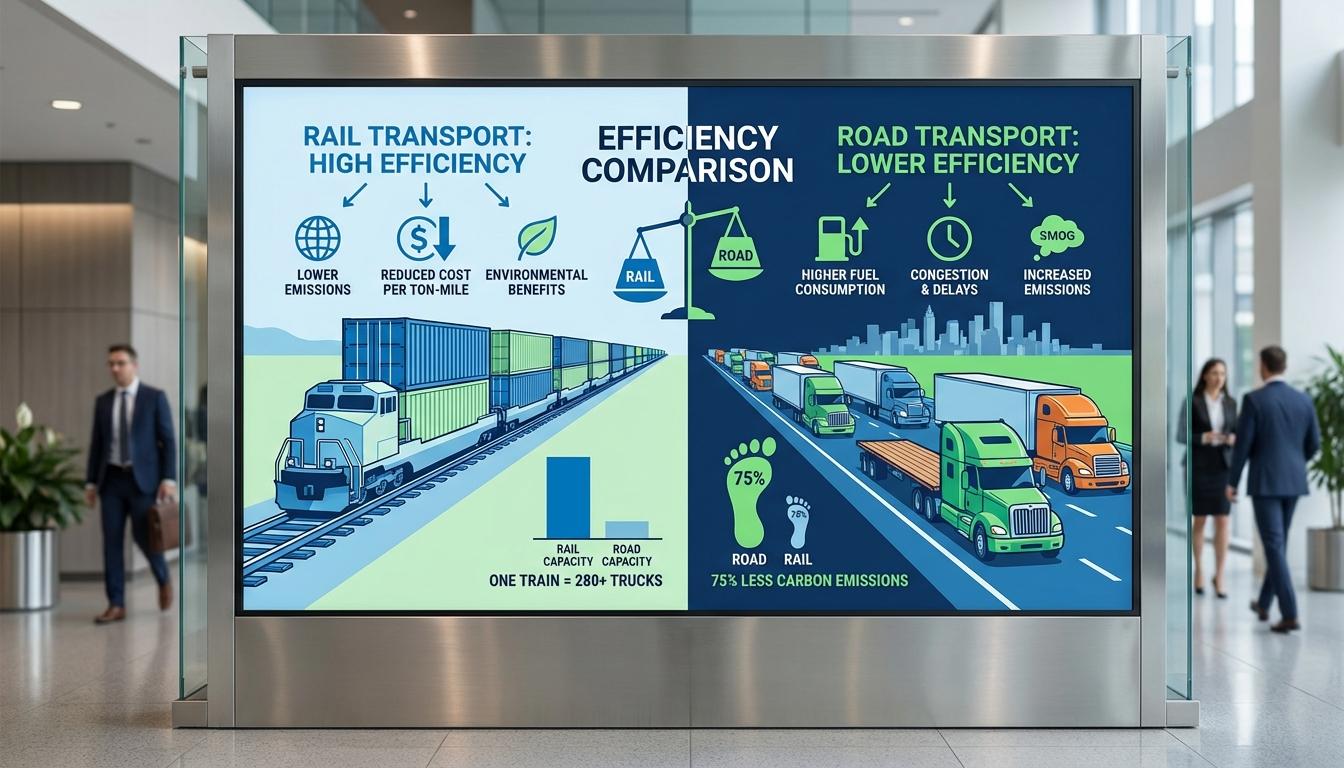

If your company has carbon reduction goals, intermodal is one of the easiest ways to hit them. Freight rail is significantly more environmentally friendly than trucking. According to the International Organization for Standardization, moving freight by rail instead of truck can reduce greenhouse gas emissions by up to 75 percent. Because one train can take hundreds of trucks off the highway, the reduction in congestion and tailpipe emissions is massive.

This is not just about “feeling good” about the environment. Many large retailers and government contractors now require their logistics partners to report on carbon footprints. By shifting a portion of your long-haul volume to rail intermodal, you are creating a measurable reduction in your environmental impact. This can be a significant competitive advantage when bidding on new contracts or appealing to eco-conscious consumers. It is a rare “win-win” where the cheaper option is also the greener option.

Think about the highway congestion we see every day. Every double-stack train you see is effectively removing 400 semi-trucks from the road. This reduces wear and tear on our national infrastructure and improves safety for everyone on the highway. For your specific case, if you are looking to improve your Corporate Social Responsibility (CSR) metrics, intermodal is the most impactful change you can make in your logistics department today.

Strategic Timing: When You Should NOT Use Intermodal

We believe in being honest about the limitations of this method. Intermodal is not a magic bullet for every shipment. There are specific situations where sticking with a traditional truck is the better move. Ready for the specifics? Here is what you need to look out for.

First, if your shipment is time-sensitive, rail might not be the answer. While rail networks have become much more reliable, they are still subject to schedule variations. A truck can drive straight through, stopping only for driver rest. A train must navigate through yards, wait for other traffic, and undergo mode transfers at both ends. If you are shipping perishable goods with a very short shelf life or high-value items needed for a “just-in-time” production line tomorrow morning, stick with a truck.

Second, if your freight is extremely fragile or requires constant monitoring, the vibrations and “slack action” of a train can be a concern. Slack action refers to the slight movement between railcars when a train starts or stops. While modern loading techniques have mitigated much of this risk, it is still a factor to consider for sensitive electronics or precision machinery. In these cases, the direct route of a truck with air-ride suspension might be worth the extra cost. Your next step is to evaluate the durability of your packaging to see if it can withstand the rigors of rail transport.

Quick Reference: Intermodal at a Glance

- Ideal Distance: 500+ miles (750+ for maximum savings).

- Primary Benefit: 15-20% cost reduction compared to trucking.

- Environmental Impact: Up to 75% reduction in CO2 emissions.

- Volume Capacity: One train equals approximately 400 trucks.

- Main Modes: Rail intermodal (train) and intermodal drayage (truck).

- Standardization: Uses ISO containers for seamless transitions.

Common Questions About Intermodal Freight Shipping

What is the difference between intermodal and multimodal transportation?

The answer is in the contract. Intermodal involves multiple carriers and multiple contracts for different legs of the journey. Multimodal uses multiple modes but operates under a single contract with one carrier who handles the entire trip from start to finish.

How much slower is rail intermodal than trucking?

Generally, you should add one to three days to the transit time of a standard truck. This accounts for the time spent at rail terminals and the scheduling of the trains themselves. For long-haul routes like New York to Los Angeles, the difference is often negligible.

Is my freight at higher risk of damage on a train?

Not necessarily. While there is more movement on a train than on a highway, the use of specialized intermodal containers and proper blocking and bracing techniques makes it very safe. In fact, because the container is sealed, the risk of theft is often lower than it is for a truck parked at a rest stop overnight.

What is a “well car” in rail intermodal?

A well car is a specialized railcar with a “depressed” center that sits close to the tracks. This design allows for double-stacking containers while still being able to clear tunnels and bridges. It is the foundation of modern rail efficiency.

Final Thoughts on Intermodal Logistics

Intermodal freight shipping is one of those areas where getting the details right makes a real difference. By understanding the interplay between rail efficiency and drayage flexibility, you can unlock significant cost savings without sacrificing the integrity of your supply chain. We have seen time and again that businesses that move their long-haul freight to the rails are better positioned to weather economic shifts and rising fuel costs. The practical takeaway is simple. If you are shipping over 500 miles and have at least a few days of lead time, you should be looking at intermodal.

Your action item right now is to identify your three longest shipping lanes. Contact a logistics provider and ask for an intermodal quote for those specific routes. Compare that to your current truckload spend. You might find that the “15-20% rule” holds true for you, putting thousands of dollars back into your budget. This is the detail that changes everything for your logistics strategy.