Ocean Freight Container Types: A Complete Visual Guide

Searching for the exact breakdown of ocean freight container types? You have come to the right place. While general shipping overviews cover the basics, you need the specific details that actually help you choose the right equipment for your cargo. We are going to get straight into what works, what does not, and exactly what you should do. Let us get specific.

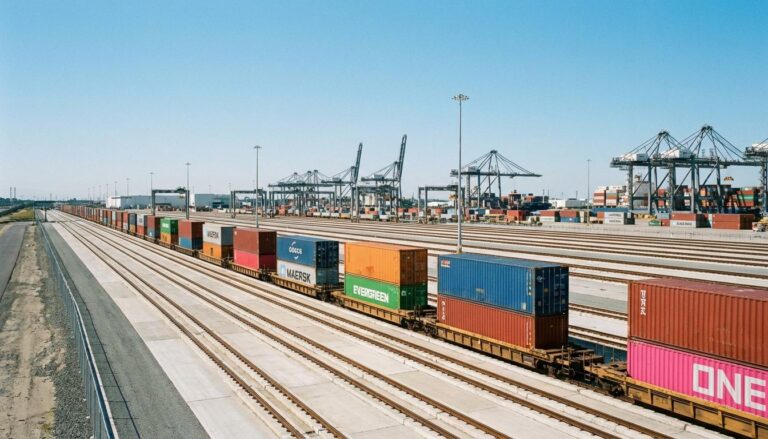

You probably already know that shipping containers are the backbone of global trade. They handle over 90 percent of non-bulk cargo and more than 60 percent of international trade. But when you are looking at a booking sheet, seeing terms like 40ft HC, XXGX, or Flat Rack can be confusing. This is the detailed breakdown you have been searching for. We will walk through the specifications, use cases, and technical codes that define modern shipping. Ready for the specifics?

Standard Dry Containers: The Industry Workhorse

When people talk about ocean freight, they are usually thinking of dry containers. These are fully enclosed, weatherproof steel boxes designed for general purpose cargo. Here is the specific answer to why they are so popular. They are versatile, secure, and compatible with almost every port in the world. If your goods do not require temperature control or have extreme dimensions, this is your default choice.

Dry containers carry the ISO code XXGX. This G stands for general purpose. These boxes are perfect for palletized goods, boxes, barrels, and even liquids if you use a flexitank. You will find them in several standard lengths. The 20ft container is considered one Twenty-foot Equivalent Unit (TEU), while the 40ft container is two TEUs.

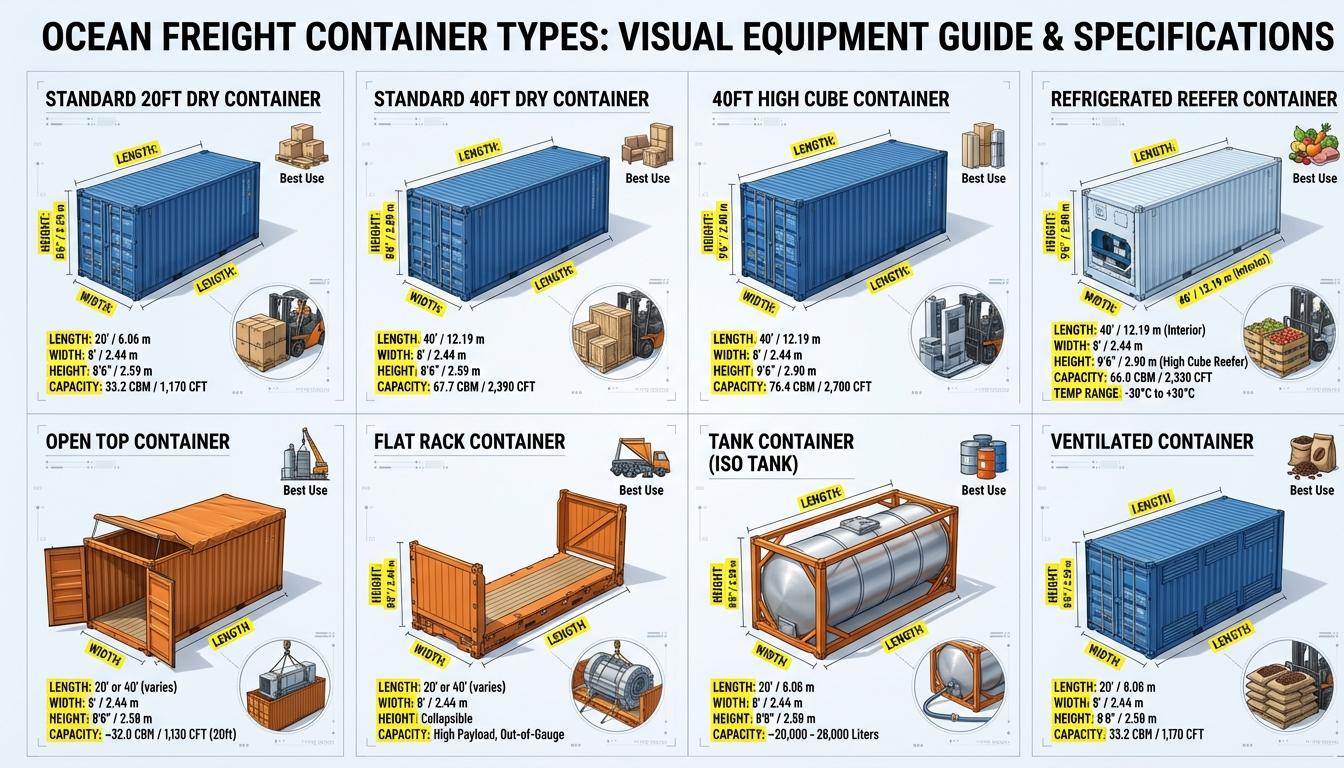

Standard Sizes and Uses:

- 20ft Dry Container: Best for heavy, dense cargo like minerals, machinery, or heavy bags of sugar. Its smaller footprint makes it easier to handle for weight-sensitive shipments.

- 40ft Dry Container: The standard for most consumer goods. It offers double the volume of a 20ft unit but is often restricted by weight limits on roads.

- 40ft High Cube (HC): This is exactly what you need to know if you ship voluminous but light goods. It is one foot taller than the standard 40ft box, standing at 9ft 6in. This extra height is a game changer for furniture or stacks of light electronics.

- 45ft, 48ft, and 53ft Containers: These larger variants are more common in specific regional trades, particularly in North America, to maximize volume for land-based intermodal transport.

Let us look at this closely. The choice between a 20ft and a 40ft container often comes down to weight versus volume. If your cargo is heavy but small, the 20ft is your best move. If your cargo is light but takes up a lot of space, go for the 40ft or the High Cube variant. For a complete overview of how these choices fit into your broader logistics strategy, check out our main guide on freight shipping methods compared.

The practical takeaway is simple. Always check the height of your pallets before booking. A standard container has an internal height of about 7ft 10in, while a High Cube gives you nearly 8ft 10in of clearance. That single foot can be the difference between fitting your entire order into one container or needing to book a second one.

Reefer Containers: Precision Temperature Control

Temperature matters. When it comes to ocean freight container types, reefer containers are the most technically advanced. These units feature built-in cooling systems designed to maintain a specific temperature range, typically from -30°C to +30°C. If you are shipping meat, fruit, vegetables, or pharmaceuticals, this is the only way to go.

So what does this mean for you? Reefer containers do not just keep things cold. They can also keep things warm in freezing climates or provide specific ventilation for commodities like onions or potatoes. Unlike dry containers, reefers require a constant power supply. They plug into the ship’s electrical system and use “gen-sets” when being transported on trucks or trains.

Key Reefer Specifications:

- Internal Space: Because of the insulation and the refrigeration machinery, reefers have slightly less internal volume than dry containers of the same external size.

- Airflow: These containers rely on “T-floor” grating. This design forces air up through the cargo, ensuring every pallet stays at the target temperature.

- Cold Chain Integrity: According to the Digital Container Shipping Association, maintaining digital logs of reefer temperatures is becoming a standard requirement for food safety.

Here is the specific situation where this applies. If your cargo is sensitive to humidity as well as temperature, reefers can also control the moisture levels inside the box. This prevents mold and spoilage. Your next step is to ensure your cargo is “pre-cooled” before it is loaded. Reefers are designed to maintain temperature, not to bring a warm product down to a cold temperature quickly.

Flat Rack and Open Top Containers for Oversized Cargo

Some things just do not fit in a box. When you have cargo that is too wide, too tall, or too heavy to load through standard doors, you need specialized equipment. This is where Flat Rack and Open Top containers come into play. These are designed for the “out-of-gauge” (OOG) market.

Flat Rack Containers (XXPX)

Flat racks have no sidewalls and no roof. They consist of a reinforced floor and two end walls. These end walls can often be folded down, turning the container into a flat platform. This is the detail that changes everything for shippers of bulldozers, yachts, or massive pipes. You can load these from the side or the top using a crane.

Open Top Containers

As the name suggests, these containers have a removable roof. Usually, the roof is replaced by a heavy-duty tarpaulin secured by “TIR” cables. Let us get specific here. These are ideal for machinery that is slightly too tall for a standard container or items that must be lowered in by a crane from above. The header bar over the door can usually be swung out of the way to make loading even easier.

In practice, this means you should be prepared for higher freight rates. Because these containers often prevent other containers from being stacked on top of them, carriers charge a premium for the “lost slots” on the vessel. When using these types of equipment, understanding intermodal freight shipping benefits is crucial because the transition from ship to rail or truck requires specialized handling for oversized loads.

Specialized Containers: Tanks, Half-Heights, and More

Beyond the standard boxes and oversized racks, there are containers built for very specific industrial needs. These are less common but vital for certain sectors like chemicals, mining, and heavy manufacturing.

Tank Containers (XXTX): These are cylindrical tanks held within a standard ISO frame. They are used for liquids, gases, and powders. Whether you are shipping food-grade oils or hazardous chemicals, tank containers provide a safe, anti-corrosive solution. They are designed for easy cleaning and can often be reused for years.

Half-Height Containers (X8UX): These are only four feet tall. Why would you want a shorter container? The real question is weight. For incredibly dense cargo like iron ore, coal, or stone, a full-height container would exceed weight limits before it was even half full. Half-heights allow for efficient loading and transport of heavy bulk materials without wasting vertical space.

Ventilated Containers: Often called “coffee containers,” these have small openings at the top and bottom to allow for natural airflow. This prevents “cargo sweat” which can ruin organic products like coffee beans or cocoa. They look like standard dry containers but provide the breathability needed for organic cargo.

The action item here is simple. If your cargo has unique physical properties, do not try to force it into a standard box. The cost of a specialized container is almost always lower than the cost of damaged cargo or a rejected shipment. Knowing when to use a specialized container versus standard options like ftl vs ltl shipping cost considerations on the land side will help you optimize your total spend.

Understanding ISO Standards and BIC Codes

How do you know exactly what kind of container is standing in front of you? The answer lies in the markings. Every container in international trade follows ISO 6346, which is the standard for coding, identification, and marking. This system ensures that a crane operator in Shanghai and a truck driver in New Jersey both know exactly what they are handling.

The most important part of this is the BIC code. According to the Bureau International des Containers, these codes identify the owner, the category, and the serial number of the unit. Here is the specific breakdown of what you will see on the container door:

- Owner Code: The first three letters (e.g., MSK for Maersk).

- Category Identifier: Usually ‘U’ for all freight containers.

- Serial Number: A unique six-digit number assigned by the owner.

- Check Digit: A single digit that validates the entire code.

- Size and Type Code: A four-character code that tells you the dimensions and the type of container (e.g., 42G1).

So what does this mean for you? When you are verifying a shipment, the Size and Type code is your best friend. The first digit represents the length, the second represents the height, and the last two characters represent the type. For example, ’42G1′ indicates a 40ft container that is 8ft 6in tall and designed for general purposes with passive ventilation.

Quick Reference: Ocean Freight Container Types at a Glance

- Dry (20ft/40ft/40ft HC): General cargo, pallets, boxes. ISO code XXGX.

- Reefer: Temperature-sensitive goods (-30°C to +30°C). Requires power.

- Open Top: Over-height cargo loaded by crane. Tarpaulin cover.

- Flat Rack: Oversized, heavy cargo like machinery or yachts. Open sides.

- Tank: Liquids, gases, and hazardous chemicals in a cylindrical tank.

- Half-Height: High-density, heavy bulk cargo like ores and minerals.

- Double Door: Dry containers with doors at both ends for easier loading.

Common Questions About Ocean Freight Container Types

What is the most common ocean freight container type?

The answer is the 40ft Dry Container. It offers the best balance of volume and cost for the majority of global consumer goods. Most shipping lines and ports optimize their operations around the 40ft and 20ft standard sizes.

Can I use a dry container for liquids?

Yes, but you need a flexitank. A flexitank is a large, flexible bladder that fits inside a standard 20ft dry container. It converts the box into a liquid carrier for non-hazardous products like wine, oils, or liquid detergents.

What is the difference between a standard 40ft and a 40ft High Cube?

The key difference is exactly 12 inches of height. A standard 40ft container is 8ft 6in tall, while a High Cube is 9ft 6in tall. This might seem small, but it increases the internal volume by about 10 percent, which is vital for light, bulky cargo.

How much weight can a 20ft container actually hold?

The short version is about 28 metric tons, but here is why that is tricky. While the container itself can hold that much, road weight limits in many countries are much lower. You must consider the weight of the truck and chassis when calculating your maximum payload.

Choosing the Right Container for Your Cargo

Selecting from the various ocean freight container types is not just about fitting your goods inside a box. It is about protecting your investment and minimizing total landed costs. Here is the step-by-step breakdown of how to choose. First, measure your cargo’s widest, tallest, and heaviest points. Second, determine if your product is sensitive to heat, cold, or humidity. Third, check if your loading dock requires specific access, such as side-loading or top-loading.

Your best move here is to consult with your freight forwarder early in the process. They can advise you on equipment availability, as specialized units like Flat Racks or Reefers can sometimes be in short supply at specific ports. Getting the equipment right from the start prevents costly delays and avoids the “re-working” of cargo at the port.

The real question is not just which container is cheapest, but which one provides the most security for your specific shipment. Whether you need a standard dry box for electronics or a specialized tank for industrial chemicals, understanding these specifications ensures your cargo moves smoothly across the ocean. Let us get your next shipment on the water with the right equipment.