WMS Selection Criteria: Finding the Right System for Your Warehouse

Are you looking for the exact breakdown of WMS selection criteria? You have come to the right place. Choosing a new warehouse management system is a high stakes decision that will impact your operations for the next decade. While general guides cover the basics of software, you need the specific details that actually help you choose between two competing platforms. We are going to get straight into what works, what does not, and exactly what you should do to find the right fit. Let us get specific.

If you are reading this, you probably already know that a warehouse management system is the brain of your distribution center. You likely know it handles picking and packing. You are looking for the detailed breakdown you have been searching for to make an objective, data-driven choice. This is one of those areas where getting it right makes a real difference. A poor choice locks you into inefficient processes and high support costs. A great choice provides the foundation for scaling your business. The real question is how you filter through the marketing fluff to find the actual capabilities your warehouse needs. For a complete overview of the broader landscape, check out our main guide on supply chain technology implementation. Now, let us look at this closely.

The Strategic Framework for WMS Evaluation

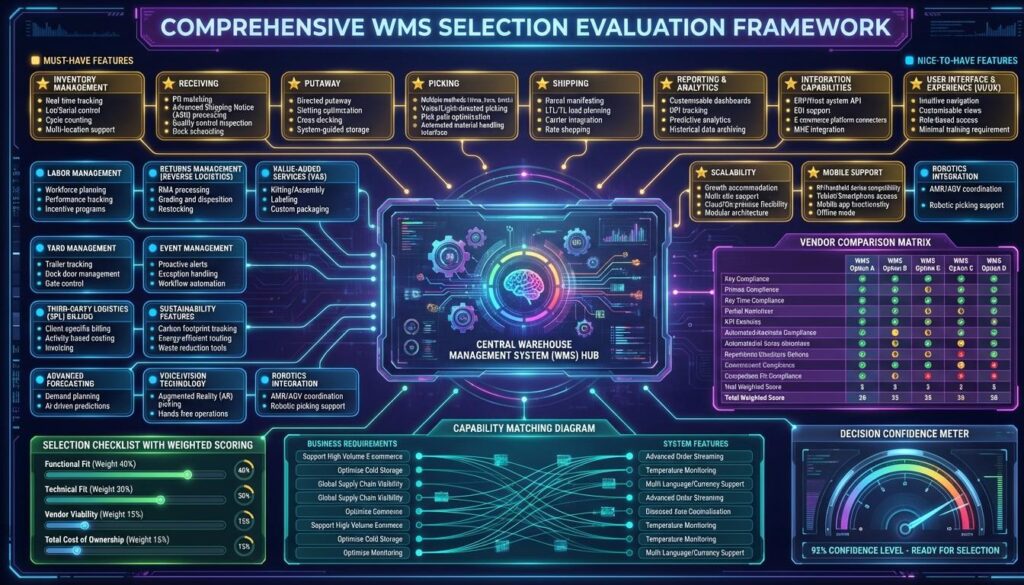

When it comes to selecting software, most people start by looking at features. That is actually a mistake. Your best move here is to start with your business goals. What are you trying to solve? Maybe you need to improve inventory accuracy to 99 percent. Perhaps you want to reduce your dock to stock time. Here is the specific answer to how you should frame your selection process. You need a structured set of business, functional, and technical requirements that allow you to compare vendors on a like for like basis.

The process starts with a deep look at your current pain points. We have seen this question come up constantly, so let us settle it. You cannot pick a system for the warehouse you have today. You must pick it for the warehouse you will have in five years. This means your criteria must include scalability and flexibility. Can the system handle a 300 percent increase in SKUs? Does it support multi site operations? Here is the step-by-step breakdown of the framework most successful organizations use.

- Process Mapping: Document every move from receiving to shipping.

- Requirement Weighting: Decide what is a must have versus a nice to have feature.

- Gap Analysis: Identify where your current manual processes are failing.

- Future State Vision: Define how you want the warehouse to operate after the upgrade.

The practical takeaway is that your criteria should be documented in an evaluation matrix. This allows you to score each WMS objectively. Without this matrix, you are just making a gut decision based on which salesperson gave the best presentation. Let us get into the details of the specific functional requirements you need to track.

Core Warehouse Management System Features

What is the actual answer to what makes a WMS functional? It comes down to how it handles the four walls of your facility. When evaluating warehouse management system features, you should look at the depth of the logic, not just the presence of a button. For example, most systems say they do putaway. But do they offer directed putaway based on weight, velocity, and hazardous material classification? That is the detail that changes everything.

Inbound Operations and Inventory Control

Your WMS functionality starts at the receiving dock. Look for systems that support Advanced Shipping Notices and blind receiving. The system should capture lot numbers, expiration dates, and serial numbers immediately. This is exactly what you need to know about inventory control. Real time visibility is non negotiable. You need to see exactly where an item is at the bin level, not just the warehouse level. Your criteria should also include support for cycle counting. This avoids the dreaded annual physical inventory shut down by keeping your accuracy high year round.

Outbound Excellence and Picking Logic

Picking is where most of your labor costs live. Your selection criteria must prioritize various picking methods. Does the system support discrete order picking, batch picking, and wave picking? For high volume e commerce, you might even need waveless order streaming. The key difference is how the system optimizes the travel path. A good WMS will minimize the distance your pickers walk by logic alone. For those looking to upgrade their tracking during this phase, understanding the nuances of barcode vs RFID tracking is essential for choosing the right hardware integration.

Reverse Logistics and Returns

Returns are the silent killer of warehouse efficiency. Most people get this wrong because they overthink the outbound side and forget the inbound side of returns. Your WMS requirements should include a robust Return Merchandise Authorization module. The system needs to guide the operator through inspection and disposition rules. Should the item be restocked, repaired, or scrapped? In practice, this means you should look for a system that updates inventory levels the moment a return is processed.

Technical and Integration Requirements

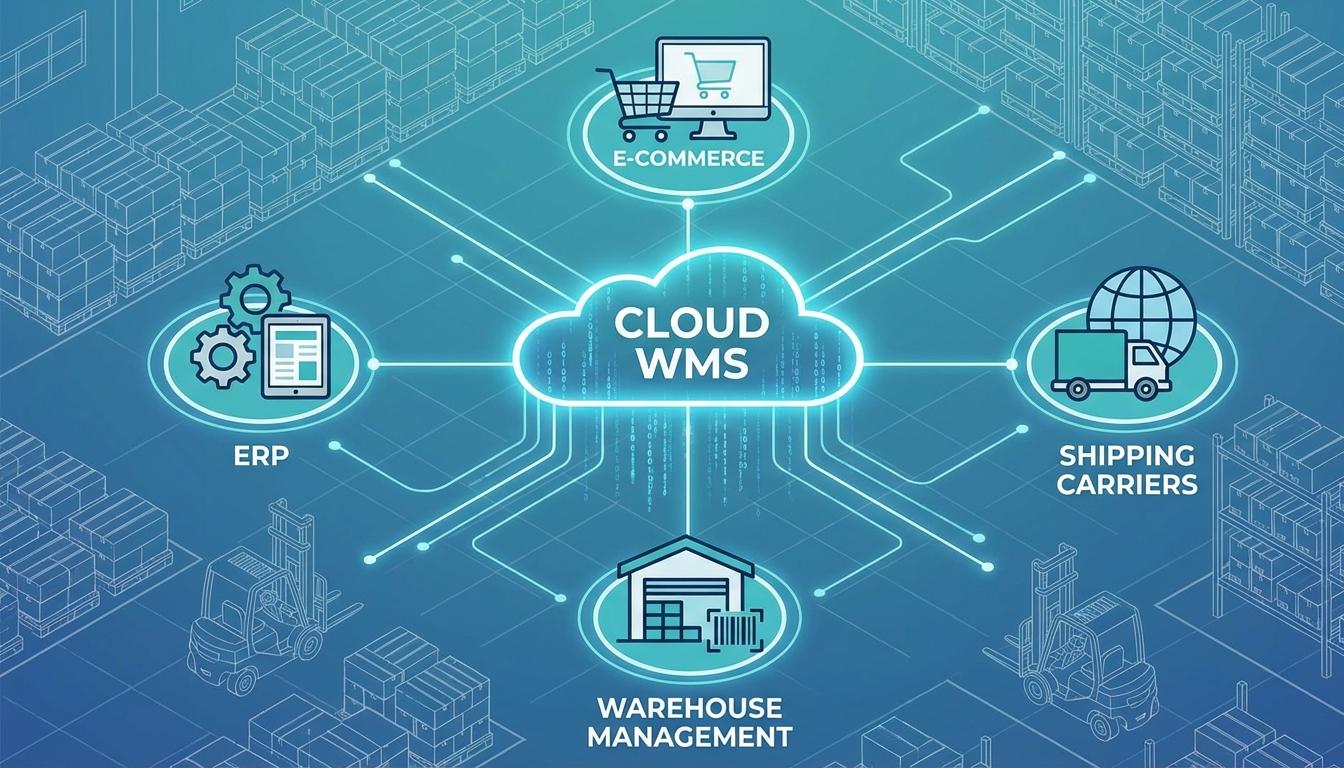

This is where it gets practical for your IT team. A WMS does not live on an island. It must talk to your ERP, your e-commerce storefront, and your carriers. When it comes to WMS evaluation, integration is often the most expensive part of the project. You need to know if the vendor provides standard APIs or if you will be paying for custom development. Custom code is a risk. It makes future upgrades difficult and expensive. Your best move is to favor standard, configurable functionality.

The deployment model is another critical factor. Most modern systems are moving to the cloud. A SaaS model reduces your internal IT burden and ensures you are always on the latest version. However, if your internet connection is unreliable, you might still consider an on premise solution. According to research from Gartner, the shift toward Cloud WMS is driven by the need for faster innovation and lower upfront capital expenditure. Here is the specific situation where this applies. If you have a single facility with very specialized needs, on premise might work. If you are growing fast across multiple sites, cloud is the way to go.

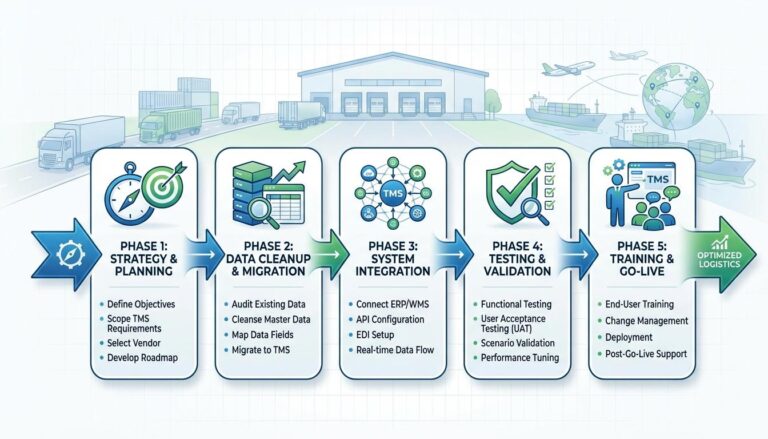

The system also needs to handle your shipping requirements. This is where warehouse software selection gets tricky. Does the WMS have a built in shipping module, or do you need a separate Transportation Management System? If you are managing a complex fleet or high freight spend, you should look at a TMS implementation guide to see how these two systems will interact. The WMS should handle the packing and labeling, while the TMS handles the rate shopping and carrier communication. Ready for the specifics on vendor selection?

Evaluating the Vendor and Implementation Partner

The software is only half the battle. The team implementing it is just as important. When you are looking at WMS selection criteria, you must vet the vendor’s industry expertise. Have they worked with companies of your size? Do they understand the specific regulations of your industry, such as food safety or pharmaceutical tracking? This is the part you actually came here for. A vendor with 3PL experience might struggle with a high volume manufacturing warehouse.

Total Cost of Ownership is the metric that matters most. Do not just look at the license fee. You need to account for implementation services, hardware costs, training, and ongoing support. A cheaper system that takes twice as long to implement is not a bargain. The action item here is simple. Ask for a detailed breakdown of all costs over a five year period. This provides a clear picture of the actual investment. Here is what works and what does not when checking references. Do not just call the three happy customers the vendor gives you. Ask to speak with a customer who has been live for at least two years and had a similar ERP integration to yours.

The roadmap for the product also matters. You are buying into a partnership. Is the vendor investing in AI and machine learning for slotting optimization? Are they adding support for autonomous mobile robots? You want a partner who is staying ahead of industry trends so your warehouse does not become a dinosaur. According to the Council of Supply Chain Management Professionals, the ability to integrate with emerging automation is becoming a top tier selection criterion for modern logistics hubs.

Quick Reference: WMS Selection Criteria at a Glance

- Functional Fit: Does it handle your specific picking, packing, and receiving workflows?

- Integration Ability: Can it connect to your ERP and e-commerce platforms via standard APIs?

- Scalability: Can the system support more users, more SKUs, and more locations as you grow?

- User Interface: Is the software intuitive for the warehouse floor staff to use with minimal training?

- Total Cost of Ownership: Does the five year cost include maintenance, support, and hardware?

- Vendor Stability: Does the vendor have the financial health and roadmap to support you long term?

- Reporting and Analytics: Does it provide real time dashboards and the KPIs you need to manage the business?

Common Pitfalls in the Selection Process

Quick reality check here. Most WMS projects fail not because the software was bad, but because the selection process was flawed. One of the biggest mistakes is over customizing. You might think your processes are unique, but they usually are not. When you force a WMS to act like your old manual system, you lose all the efficiency gains the software was designed to provide. Your next step should be to adapt your processes to the software’s “best practice” workflows whenever possible.

Another common error is excluding the end users from the process. Your warehouse managers and floor supervisors are the ones who will live in this system every day. If they hate the interface or find the workflows clunky, the implementation will struggle. This is the detail that changes everything. Including your team in the scripted demos ensures you get buy in from the start. They will catch small operational issues that an IT manager might miss.

Lastly, do not skip the scripted demo. Never let a vendor show you a generic “canned” demo. Give them three of your hardest scenarios. For example, show how the system handles a partial shipment where one item is out of stock and needs to be backordered. Or show how it handles a return of a kit where one component is missing. This is how you see the true WMS comparison in action. Let us cut to what matters for your final decision.

Common Questions About WMS Selection Criteria

What is the most important factor in choosing a WMS?

The answer is functional fit. The most advanced system in the world is useless if it cannot handle your specific order profiles or inventory types. Start with your must have requirements and do not compromise on them. Everything else, from price to UI, is secondary to the system’s ability to actually run your warehouse.

Should I choose a Tier 1 or Tier 2 WMS?

This depends on your complexity. Tier 1 systems offer incredible depth and can handle massive, multi site operations with complex automation. However, they are expensive and difficult to implement. Tier 2 systems are often more agile and easier to use for mid market companies. The real question is whether you need the 20 percent of advanced features that a Tier 1 system provides.

How long does the selection process usually take?

For most mid sized companies, a thorough selection process takes between three to six months. This includes mapping your processes, issuing an RFP, viewing demos, and conducting site visits. Rushing this phase is the fastest way to make a mistake that you will regret for years. Take the time to get the criteria right.

Is a cloud based WMS secure enough for my data?

Yes, and in many cases, it is more secure than an on premise server. Major WMS providers use enterprise grade security and redundancy that most individual companies cannot afford to maintain on their own. Just ensure the vendor meets specific compliance standards relevant to your industry, such as SOC2 or HIPAA.

Do I really need an external consultant for this?

If you have never selected a WMS before, a consultant can save you a lot of money by helping you avoid common traps. They bring an objective perspective and a library of existing requirements that can speed up the process. However, you still need an internal team that is deeply involved to ensure the system meets your unique operational needs.

Action Plan for Your Selection Journey

The direct answer to your next step is to build your requirements matrix. Start by talking to your floor supervisors and identifying the top three things that slow them down every day. Use those pain points to form the core of your criteria. Once you have your list, weight each item. Is “voice picking support” a must have or just a dream for the future? Be honest with yourself about what you actually need to run the business today.

Remember that the goal of WMS selection criteria is to remove emotion from the decision. You are looking for the best tool for the job. By focusing on functional fit, technical compatibility, and vendor stability, you create a foundation for long term success. This is exactly what you need to know to move forward with confidence. The practical takeaway is simple. Document your needs, test them against the vendors, and trust the data. Your warehouse efficiency depends on it. Now, go get started on that process map.