TMS Implementation: A Roadmap for Success

Are you feeling overwhelmed by the prospect of a TMS implementation? You are certainly not alone. While the promise of reduced freight spend and crystal clear visibility is exciting, the actual process of getting a transportation management system off the ground can feel like trying to steer a ship through a narrow fog. We have seen many teams start with high hopes only to get bogged down in data messiness or integration headaches. This is exactly why a structured roadmap is not just helpful, it is essential for your success.

You probably already know that a TMS can automate your carrier tendering and help you find the best rates. But you are here because you need to know the specific steps to actually make that happen without disrupting your current operations. This guide is the detailed breakdown you have been searching for. We are going to move past the surface level advice and get into the practical mechanics of a successful deployment. Let us get specific about how you can turn this software into a high performance engine for your supply chain.

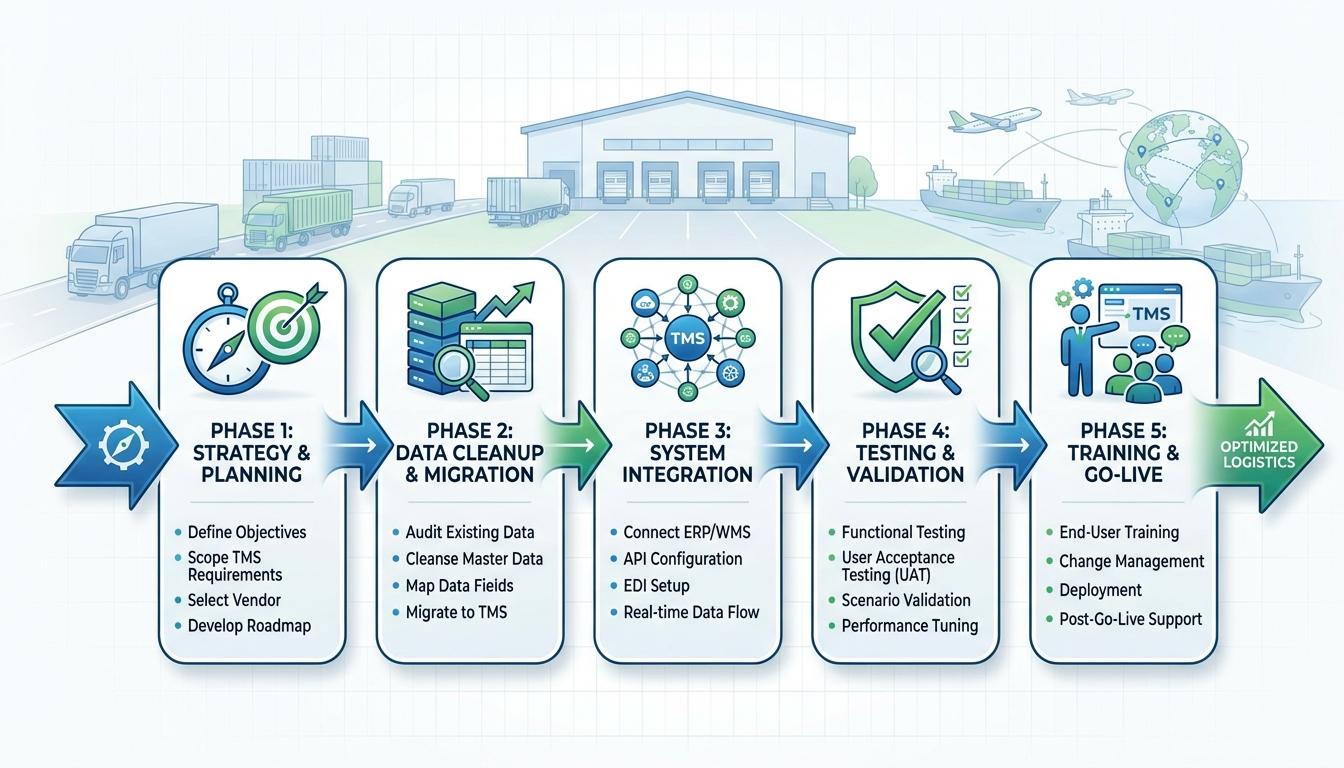

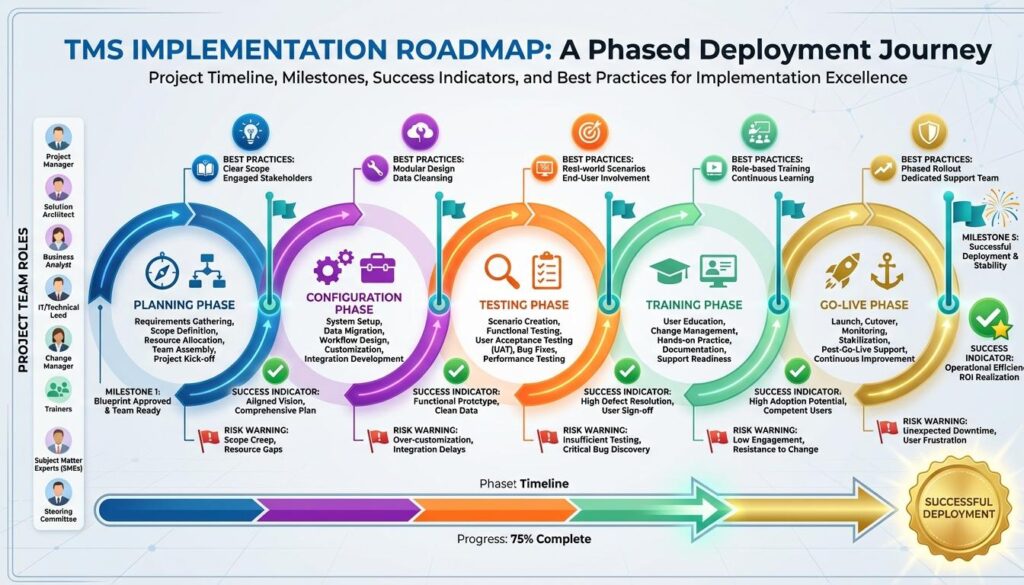

Phase 1: Setting Your Strategic North Star

When it comes to TMS implementation, the details matter right from the start. You cannot hit a target if you have not defined exactly what it looks like. We always recommend beginning with a strategic assessment that goes beyond “saving money.” What specific pain points are you trying to kill? For some, it is the three hours spent every morning manually calling carriers. For others, it is the total lack of data on which lanes are bleeding cash.

The short version is that you need SMART goals. We are talking about Specific, Measurable, Achievable, Relevant, and Time-bound objectives. You should pick three to five key performance indicators (KPIs) that will define your success. Common ones we see include your tender acceptance rate, average load planning time, and transit-time variance. If you can decrease your invoice errors by 15 percent in the first six months, that is a win you can actually take to your leadership. For a complete overview of how these pieces fit into your broader tech stack, check out our main guide on supply chain technology implementation.

Your next step is to create a project charter. This document should clearly define who is responsible for what. You need a project manager, a lead for your data, and most importantly, an executive sponsor who can clear roadblocks. Here is the thing most people miss: if you do not have buy-in from the people actually moving the freight on the floor, your implementation will stall. Get them involved in the goal-setting phase so they feel ownership of the outcome. Ready for the specifics of the data phase?

Phase 2: The Data and Process Cleanup

This is where it gets practical, and honestly, where most projects either succeed or fail. Your TMS software is only as good as the data you feed it. If you upload messy carrier records or outdated contracts, the system will give you useless routing suggestions. We call this the “garbage in, garbage out” rule. Before you even touch the new software, you need to conduct a massive audit of your current information.

Start by organizing your master data. This includes every carrier record, your lane history for at least the last 12 months, and your current fuel tables. You also need to standardize your accessorial codes. If one carrier calls a residential delivery “RES” and another calls it “HOME_DEL,” the system will struggle to compare costs accurately. Here is a step-by-step breakdown of what to clean up first:

- Carrier Contracts: Ensure every rate, expiration date, and surcharge is digitized and up to date.

- Ship-to/Ship-from Points: Verify every address and geocode them if possible to ensure accurate mileage calculations.

- Routing Logic: Map out exactly how you choose a carrier today. Is it by price? Reliability? A “handshake” deal? You need to turn these habits into clear rules.

- Financial Data: Ensure your cost centers and GL codes are ready for integration.

Once your data is clean, you must map your “as-is” processes. This means documenting exactly how an order moves from your ERP to a truck. Do not just document how it is *supposed* to work, document how it *actually* works, including all the manual workarounds. This is the only way to identify where the new system can actually add value. If you are also looking at how this data ties into your warehouse, you might find our insights on WMS selection criteria and features useful for understanding how different systems talk to one another.

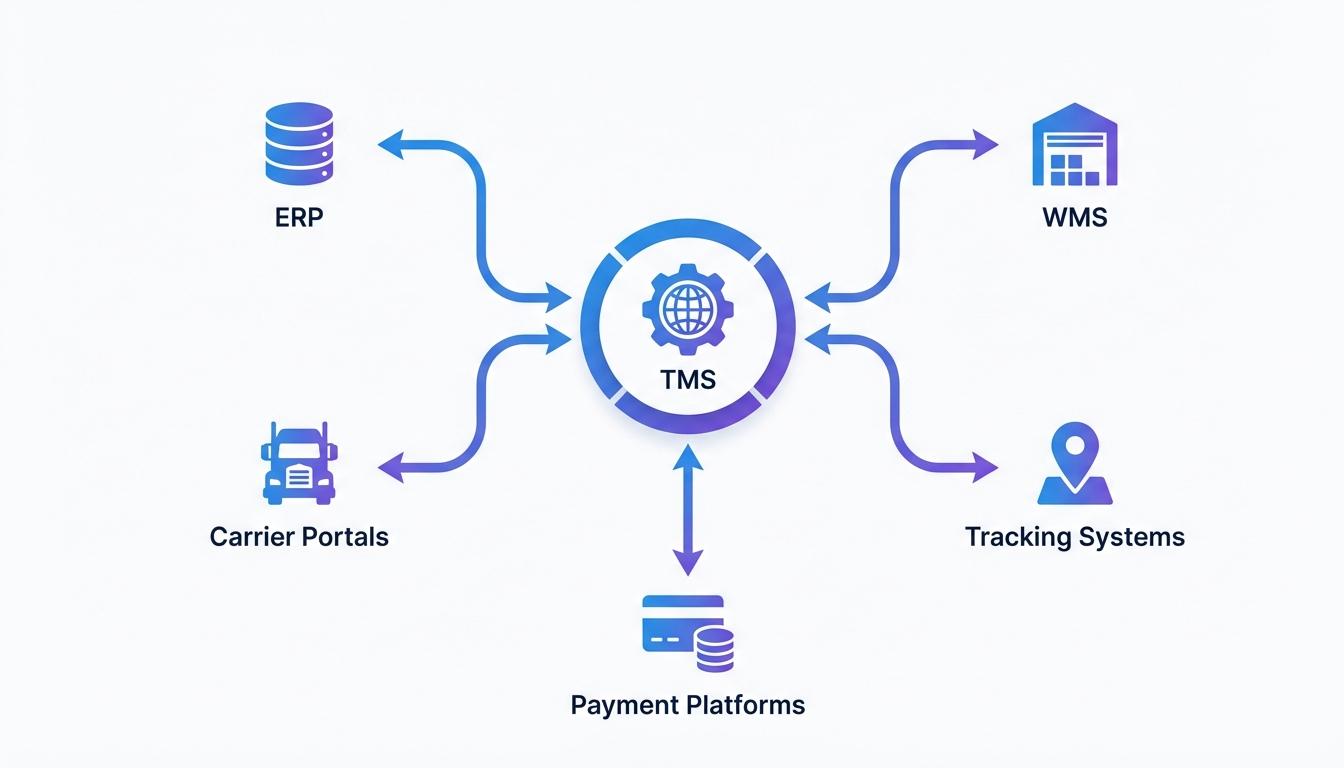

Phase 3: Integration and Configuration Strategy

How does the TMS actually talk to your other systems? This is the part you actually came here for. A modern TMS deployment is rarely a standalone event. It needs to live in the center of a web that includes your ERP, WMS, and your carriers’ systems. According to Oracle documentation, the most critical integrations are those that synchronize order fulfillment with transportation planning in real-time.

Let us look at this closely. You will likely need to set up APIs or EDI connections for several key functions. For example, integrating with a tool like PC-Miler is essential for accurate routing and mileage. If you want real-time tracking, you might integrate with a platform like Samsara. For payments and freight audit, many companies connect their TMS to WEX. The goal is to create a seamless flow of data where an order created in your ERP automatically appears in your TMS for tendering.

Configuration is where you tailor the TMS features to your specific business. This is not the same as customization, which involves changing the software code. Configuration is simply flipping the right switches within the existing software. You will need to set up your routing guides, define your consolidation rules, and establish your carrier ranking logic. Should the system always pick the cheapest carrier, or the one with the highest on-time delivery rate? These are the decisions that change everything. For those interested in how hardware like scanners interacts with this software, you can learn more about barcode vs RFID tracking and how it feeds into your visibility data.

Phase 4: The Testing Gauntlet

You are looking for the real answer on how to avoid a disastrous go-live, and the answer is rigorous testing. This is not just a quick check to see if the buttons work. We are talking about a full, end-to-end simulation of your shipment flows. You need to take a real order from your system and follow it all the way through tendering, tracking, delivery, and finally, the freight bill audit and payment.

We recommend a two-stage testing approach. First is the system integration testing (SIT), where your IT team ensures the data is moving correctly between the ERP and the TMS. The second, and more important, is User Acceptance Testing (UAT). This is where your actual dispatchers and planners get their hands on the system. Here is what that actually looks like in practice:

- Standard Scenario: A simple, single-stop truckload shipment. Does it tender correctly?

- The Exception Scenario: A shipment that gets delayed or needs a last-minute carrier change. Can the system handle the pivot?

- The Multi-Stop Scenario: Testing the consolidation logic for LTL shipments.

- The Billing Scenario: Does the carrier’s invoice match what the TMS calculated? If not, is the dispute process working?

The practical takeaway is this: do not rush this phase. It is much cheaper to find a bug in a test environment than it is when a driver is sitting at your dock waiting for paperwork. Research from industry experts like Descartes highlights that successful implementations often spend 30 percent of the total project timeline on testing alone. If you find issues, document them, fix them, and then test that exact scenario again. Only move forward when you have zero critical errors.

Phase 5: Training and the Human Element

What is the actual answer to why TMS implementations fail? It is usually not the software. It is the people. Change is hard, and many of your team members have spent years developing their own manual habits and workarounds. If they feel like the new freight management system is a burden rather than a tool, they will find ways to bypass it. This is why change management is your best move here.

Your training should be role-specific. Your warehouse team does not need to know how to set up carrier contracts, and your accounting team does not need to know how to optimize routes. Break your training into small, digestible sessions that focus on the daily workflows of each specific group. Use “super users” who are tech-savvy and well-liked by their peers to lead these sessions. They can speak the language of the floor and provide real-world context that an IT trainer might miss.

During the launch, provide hyper-care support. This means having experts available on the floor (or virtually) for the first week or two of go-live. When someone gets stuck, they need an answer immediately, not a help desk ticket that will be answered in 24 hours. Monitor user behavior closely. If you see people manually entering data that should be automated, step in and find out why. Is it a training issue, or is there a flaw in the system configuration? Addressing these manual habits early is the only way to ensure long-term adoption.

Quick Reference: TMS Implementation at a Glance

- Define Goals: Set SMART KPIs like tender acceptance and transit-time variance.

- Audit Data: Clean your carrier records, lane history, and fuel tables.

- Map Processes: Document “as-is” workflows to identify where automation helps.

- Integrate Systems: Connect ERP, WMS, and tracking tools like Samsara via APIs.

- Rigorous Testing: Run end-to-end simulations of both standard and exception scenarios.

- Role-Based Training: Focus on daily workflows for specific user groups.

- Phased Launch: Start with a pilot or specific region before a full rollout.

- Continuous Optimization: Review KPIs monthly and adjust routing logic.

Common Questions About TMS Implementation

How long does a typical TMS implementation take?

The answer is that it depends on the complexity, but most mid-market implementations take between three to six months. Simple cloud-based systems can be up in weeks if your data is clean, while global enterprise deployments can take a year or more. The data cleanup and integration phases usually consume the most time.

What is the biggest mistake companies make during deployment?

The most common pitfall is neglecting data quality. Many companies assume the software will “fix” their bad data, but the opposite is true. Poor data leads to bad routing decisions, which causes users to lose trust in the system and return to manual spreadsheets. Audit your carrier contracts and addresses before you start.

Do we need a consultant to manage the implementation?

Not necessarily, but it can help if your internal IT team is stretched thin. If you have a dedicated project manager who understands logistics and a tech-savvy lead for your data, you can certainly handle it in-house. However, a specialist can help you avoid common configuration mistakes that lead to long-term efficiency gaps.

Which integrations are absolutely essential for a TMS?

At a minimum, you need your ERP or Order Management System (OMS) to feed orders into the TMS. Beyond that, a mileage/routing engine like PC-Miler and a carrier connectivity platform for EDI/API tendering are critical. Real-time visibility integrations and freight payment systems are the next level of maturity for most shippers.

Now for the part you actually came here for. Once the system is live, the work is not over. You need to enter a phase of continuous optimization. Monitor your KPIs weekly. Are you seeing the cost reductions you planned for? If your tender acceptance is low, you might need to revisit your routing guides or carrier rankings. This is the detail that changes everything: a TMS is not a “set it and forget it” tool. It is a performance system that requires regular tuning to stay effective in a changing market. Your best move right now is to begin that data audit we discussed. Get your carrier contracts in order, and you will be miles ahead of the competition when your implementation starts.