Barcode vs RFID: Choosing the Right Tracking Technology

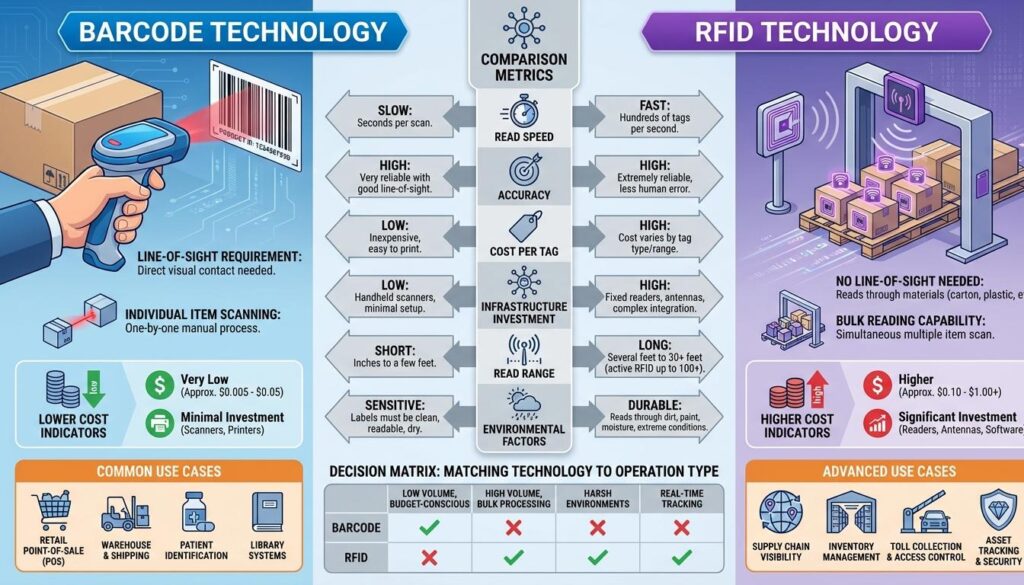

Searching for the definitive answer on barcode vs RFID? You have likely reached a point where manual counting just is not cutting it anymore. While both technologies serve the same ultimate goal of identifying items, the way they achieve that goal changes everything for your daily operations. We are going to break down the technical differences and practical applications so you can make a confident choice for your facility. Let us get specific.

If you are reading this, you probably already know the basics of inventory management. You are looking for the specific answer, not a general overview of why tracking matters. This is the detailed breakdown you have been searching for to decide which automatic identification method fits your budget and your speed requirements. Ready for the specifics? Let us get into the details.

The Fundamental Mechanics: Optical vs. Radio Waves

When it comes to barcode scanning, the technology is strictly optical. A reader emits a laser or a light beam to capture the contrast between the black and white patterns on barcode labels. This process requires a direct line of sight. If the label is smudged, torn, or facing the wrong direction, the scanner cannot read it. It is a one-to-one interaction that happens in close proximity, usually within a few inches or feet. This is exactly what you see at a grocery store checkout where every item must be physically handled to be recorded.

RFID tracking works on a completely different principle. Instead of light, it uses radio waves to communicate between RFID tags and a reader. The most significant advantage here is that you do not need a line of sight. A reader can wake up an embedded chip inside a tag through cardboard, plastic, or even wood. This allows for reading tags from much further away, with some systems reaching up to 300 feet. Here is the thing most people miss: because it uses radio waves, you can read hundreds of items simultaneously without ever opening a box.

The practical takeaway is simple. If your process allows you to touch every item, barcodes are reliable. If you need to know what is inside a sealed pallet without breaking the wrap, RFID is your only real option. This is the detail that changes everything for high-volume warehouses that cannot afford to stop and scan every single unit manually.

Operational Speed and Bulk Data Capture

How much time does your team spend on inventory counts? This is where the gap between these two technologies becomes massive. Barcode scanning is a serial process. You scan item A, then item B, then item C. Each scan takes at least half a second of focused effort. In a warehouse with 10,000 items, that is hours of labor just to confirm what is on the shelves. It is a slow, manual process that is always prone to human error or skipped items.

RFID changes the math entirely. Because radio waves travel in all directions, an RFID reader can capture data from multiple tags in less than 100 milliseconds per tag. We have seen video demonstrations where a pallet of 500 items is scanned in seconds just by pushing it through an RFID portal. This is why inventory tracking technology is shifting toward RFID in environments where speed is the primary bottleneck. According to research from GS1, RFID can achieve up to 100 percent inventory accuracy because it removes the “human” element of aiming a scanner at a label.

So what does this mean for you? If you are moving high volumes of goods through a loading dock, the speed of RFID can prevent backups. Your next step is to look at your “scan points.” If those points are creating a line of employees waiting to use a handheld, you are losing money on labor that RFID could easily save. Let us look at this closely. The time saved in a single month of warehouse-wide inventory counts often pays for the higher cost of the RFID infrastructure.

Data Capacity and Read/Write Capabilities

The amount of information you can store is another key difference. A standard barcode is essentially a pointer. It contains about 20 to 24 characters, usually a serial number or a Global Trade Item Number (GTIN). To know anything else about the product, your barcode scanning device must be connected to a database that tells it what that number means. Once a barcode is printed, the data on it is permanent. You cannot update the label without printing a new one.

RFID tags are much more sophisticated. Most tags can hold up to 2 kilobytes of data. This is enough to store not just a serial number, but also the product history, manufacturer details, and even expiration dates directly on the item. This is where it gets practical: RFID tags are often read/write. You can update the information on the tag as it moves through your supply chain. For example, a tag could be updated with a “quality check passed” timestamp at one station and a “ready for shipping” status at another.

Here is the specific situation where this applies. If you work in an industry with strict compliance or expiration requirements, like pharmaceuticals or fresh food, having that data on the tag is a lifesaver. You do not have to rely solely on your central database being perfectly synced. The item carries its own history with it. For a complete overview of how these tools fit into your larger software ecosystem, check out our main guide on WMS selection criteria and features.

Durability in Harsh Environments

Where are your items stored? The environment plays a huge role in choosing between barcode vs RFID. Barcode labels are usually made of paper or thermal film. They are exposed on the outside of the packaging. If they get wet, dirty, or scratched, they become useless. In a dusty warehouse or an outdoor yard, the failure rate of barcodes can be a constant frustration for your team. You find yourself constantly reprinting labels just to get a single scan.

RFID tags are far more resilient. The chip and antenna are often encased in plastic, resin, or even embedded inside the product itself. They are protected from the elements. Dirt and grease do not stop radio waves. This makes RFID the superior choice for tracking assets like shipping containers, tools, or industrial parts that live in rough conditions. They can survive being washed, painted over, or dragged across a warehouse floor.

The real question is: can your labels survive your workflow? If you find yourself replacing labels frequently, your best move here is to switch to a ruggedized RFID tag. While the individual tag costs more than a paper barcode, you only have to apply it once. This is one of those areas where getting it right makes a real difference in long-term maintenance costs. The labor spent replacing damaged barcodes is a hidden cost that many managers overlook when comparing prices.

Cost Analysis: Upfront Investment vs. Long-Term ROI

The direct answer is that barcodes are cheaper to start. You can print a barcode for less than a cent using a standard thermal printer. The handheld scanners are also relatively inexpensive and easy to set up. This low barrier to entry is why barcodes remain the standard for retail point-of-sale and small-scale operations. If your budget is tight and your volume is low, barcodes are a perfectly logical choice.

RFID requires a higher initial investment. You need specialized printers to encode the chips, and the tags themselves can cost anywhere from ten cents to several dollars each depending on their durability. You also need to install readers and antennas at key locations like dock doors. However, you have to look at the labor savings. RFID eliminates the need for manual scanning, which can reduce your labor costs significantly over time. We have seen companies reduce their inventory count time from three days down to two hours by switching to RFID.

Here is the step-by-step breakdown for your financial decision:

- Calculate your current scanning labor: How many hours a week do employees spend scanning items?

- Estimate the error rate: How much do lost items or shipping errors cost you annually?

- Compare to RFID infrastructure: Weigh the cost of readers and tags against those labor and error savings.

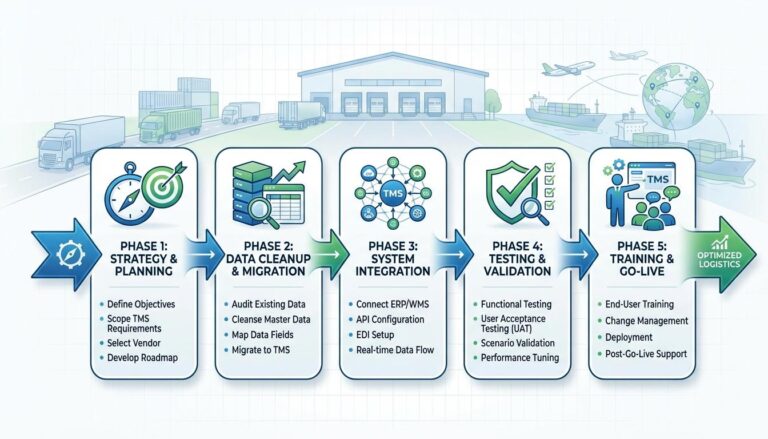

In many cases, the high-volume environment makes the ROI of RFID undeniable within the first year or two. If you are also looking at how this data flows into your shipping operations, you might find our TMS implementation guide helpful for coordinating those logistics. The key is to look at the total cost of ownership, not just the price of a single label.

Implementation and Technical Challenges

Do not expect to plug in an RFID system and have it work perfectly in five minutes. RFID setup is more complex than barcode scanning. Radio waves can be finicky. For instance, metal surfaces reflect radio waves, and liquids can absorb them. If you are tracking cases of bottled water or metal engine blocks, you will need specialized tags designed for those environments. You also have to deal with “ghost reads,” where a reader accidentally picks up a tag that is thirty feet away on a different shelf.

Barcodes are much simpler to implement. The technology is “what you see is what you get.” If the scanner hits the label, it works. There is very little interference to worry about. Most warehouse staff already know how to use a barcode scanner with zero training. If your team turnover is high or you need a system that works “out of the box” without a specialized engineer, barcodes have a massive advantage in simplicity.

When it comes to supply chain technology implementation, the complexity of your environment dictates your path. If you have a clean, open warehouse with mostly dry goods, RFID is a dream. If you are working in a cramped space filled with metal racking and liquids, you will need a professional site survey to ensure your RFID readers are placed correctly. For more on navigating these hurdles, see our advice on supply chain technology implementation and how to manage the transition smoothly.

Quick Reference: Barcode vs RFID at a Glance

- Scanning Method: Barcodes are optical (line of sight); RFID uses radio waves (no line of sight).

- Read Range: Barcodes are close range (inches to feet); RFID is long range (up to 300 feet).

- Data Speed: Barcodes scan one at a time; RFID scans hundreds simultaneously in seconds.

- Data Type: Barcodes are read-only; RFID is read/write and can be updated.

- Durability: Barcodes are sensitive to damage; RFID is highly resistant to dirt and moisture.

- Initial Cost: Barcodes are very low cost; RFID is a significant upfront investment.

- Accuracy: RFID significantly reduces human error during large inventory counts.

Common Questions About Barcode vs RFID

Which is faster for inventory tracking: barcode or RFID?

The answer is RFID. Because it can scan multiple tags at once without requiring the operator to see each label, it can process thousands of items in a fraction of the time it takes to scan barcodes one by one. This speed is the primary reason large retailers like Walmart have mandated its use for certain categories.

Are RFID tags more expensive than barcode labels?

Yes, they are considerably more expensive. A barcode is essentially free if you are already printing a packing slip, whereas an RFID tag contains an electronic chip that costs money to manufacture. However, the long-term savings in labor often offset this price difference in high-volume settings.

Can RFID replace barcodes entirely?

Not quite. While RFID is superior for bulk tracking, barcodes are still the gold standard for individual item checkout at the consumer level because they are so cheap and universal. Many businesses use a hybrid system where the pallet is tracked via RFID and the individual units have barcodes for retail sales.

What affects RFID accuracy?

Metal and liquid are the two biggest enemies of RFID accuracy. Metals reflect the signal and liquids absorb it, which can lead to missed reads. Fortunately, specialized “on-metal” tags and high-performance antennas can solve most of these issues in modern setups.

Do barcodes require line-of-sight?

Yes, always. The scanner must be able to “see” the black and white lines clearly. If the label is on the bottom of a box or inside a shipping container, a barcode scanner cannot read it without someone physically moving the item.

Choosing Your Path Forward

Selecting between barcode vs RFID is not about finding the “better” technology, it is about finding the right tool for your specific workflow. If you are running a small shop or a low-volume distribution center, the simplicity and low cost of barcodes are hard to beat. They do the job reliably without requiring a complex setup. Your best move here is to stick with high-quality thermal labels and reliable handheld scanners.

However, if you are struggling with inventory accuracy, facing labor shortages, or dealing with massive volumes of stock, RFID is the detail that changes everything. It automates the most tedious part of your operation and provides real-time visibility that barcodes simply cannot match. The practical takeaway is to start where your biggest bottleneck exists. If your loading dock is a mess of manual scanning, start there with a pilot RFID program.

The action item here is simple. Evaluate your volume and your labor costs. If you are ready to scale and need 100 percent accuracy, the investment in RFID tracking will pay for itself. If you are just starting out, refine your barcode labels process first. Whichever you choose, getting away from manual entry is the first step toward a modern, efficient supply chain. Choose the technology that fits your speed, and the ROI will follow.