Implementing Supply Chain Technology: A Practical Roadmap

Have you ever felt like your supply chain is held together by spreadsheets, legacy software, and a fair amount of hope? You are definitely not alone. Many of the leaders we talk to feel like they are running a marathon while wearing lead boots. The world is moving faster, customers want things yesterday, and the old ways of doing things just cannot keep up anymore. If you have been looking for a way to modernize but feel overwhelmed by the sheer number of options, you have come to the right place.

We are going to explore the world of supply chain technology implementation together. This is not just about buying a new piece of software and hoping for the best. It is about a fundamental shift in how your business operates. We have gathered the most important insights and data to help you understand what actually works and what is just noise. Whether you are curious about AI, wondering if you need a new warehouse system, or trying to figure out why your last tech rollout didn’t quite land, we have got you covered.

This guide is designed to be your ultimate resource. We will break down the definitions, look at the core technologies that are changing the game, and provide a practical roadmap for your own journey. We will also tackle the tough stuff, like how to manage change and measure your success. Let us get started because the future of your supply chain is waiting.

What Exactly Is Supply Chain Technology Implementation?

Before we go any further, let us clear up some terminology. It is easy to get lost in the alphabet soup of ERP, WMS, and TMS. In simple terms, supply chain technology implementation is the process of selecting, deploying, and integrating digital tools into your operations. This includes everything from the software that tracks your trucks to the robots that pick orders in your warehouse. It is the practical “how-to” of making tech work for you.

However, there is a bigger picture here. You will often hear the term digital supply chain transformation. While implementation is about the specific tools, transformation is the overarching strategy. It is about rethinking your entire operating model using data and connectivity. Think of implementation as installing a new engine, while transformation is redesigning the whole car to be electric and self-driving. You need both to really move the needle.

Another term you will see is supply chain digitization. This is the act of turning analog or manual processes into digital ones. If you are still using paper clipboards to check inventory, digitization is the first step on your journey. By converting that paper trail into digital data, you open the door to real-time visibility and advanced analytics. It is the foundation that everything else is built upon.

The Rise of Supply Chain Automation

One of the most exciting parts of this process is supply chain automation. This involves using technology like robotics, autonomous vehicles, and AI-driven workflows to handle tasks that used to require manual labor. We are seeing a massive shift here. By 2025, robots are expected to manage a significant share of warehouse tasks. This does not just save on labor costs. It significantly improves accuracy and allows your human team to focus on more strategic work. What we found is that automation is no longer a luxury for the giants. It is becoming a necessity for everyone.

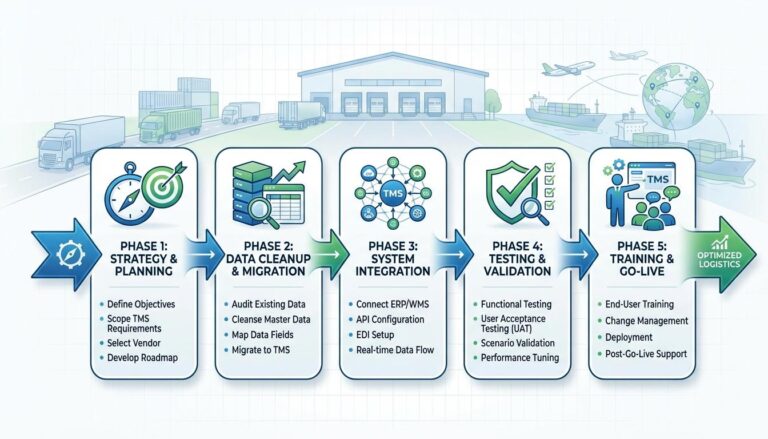

Logistics Software Implementation

Within the broader supply chain, logistics software implementation focuses specifically on the movement of goods. This includes your Transportation Management Systems (TMS) and Warehouse Management Systems (WMS). These are the workhorses of the logistics world. They help you optimize routes, manage your fleet, and keep your warehouse running like a Swiss watch. If your goal is to improve last-mile delivery or reduce shipping costs, this is where you will spend a lot of your time.

Why Organizations Are Investing Heavily Right Now

You might be wondering why there is such a sudden rush to adopt these technologies. The answer lies in the increasing volatility of the global market. Research suggests that disruptions lasting longer than a month now happen every few years on average. These events can cost a business a significant share of an entire year’s profit over a decade. That is a staggering number. Technology is no longer just about efficiency. It is about survival and resilience.

Cost and productivity remain huge drivers as well. Operations leaders are using AI and automation to streamline everything from quality control to distribution. According to the PwC 2025 Digital Trends in Operations Survey, 62% of executives see AI tools as very effective in boosting productivity and managing costs. When you can do more with less, your bottom line feels the impact immediately.

Customer expectations have also reached an all-time high. Whether you are B2B or B2C, your customers want transparency. They want to know exactly where their order is and exactly when it will arrive. Real-time data and tracking technology make this possible. If you cannot provide that level of service, your customers will find someone who can. Here is the bottom line. Tech adoption is the price of entry in the modern market.

The Pressure of Regulatory and ESG Requirements

There is also a growing need for better data to meet environmental, social, and governance (ESG) goals. Governments and consumers alike are demanding to know where products come from and how they were made. Technologies like blockchain and IoT sensors provide an immutable record of a product’s journey. This makes compliance much easier and builds trust with your audience. For a deeper look at how to track these assets, check out our guide on barcode vs RFID tracking. It is a great starting point for understanding your traceability options.

The Core Technology Domains You Need to Know

When we look at the landscape of supply chain technology implementation, a few key domains stand out. These are the building blocks of a modern, connected network. Most successful companies are not just picking one. They are creating an ecosystem where these technologies work together.

Cloud Platforms and Multi-Enterprise Networks

Cloud computing is the backbone of everything else. It allows you to share data in real-time across your entire organization and with your partners. Gone are the days of expensive, on-premise servers that are hard to update. By 2025, a majority of supply chains are expected to rely on cloud-based systems. This shift enables faster responses to changes in demand and supply because everyone is looking at the same “version of the truth.”

Multi-enterprise platforms take this a step further. They act as central hubs that tie together your internal departments with suppliers, logistics providers, and customers. Imagine being able to see a delay at a supplier’s factory and instantly knowing how it will affect a customer’s delivery three weeks from now. That is the power of a connected cloud network. It turns a siloed chain into a collaborative ecosystem.

AI, Machine Learning, and Advanced Analytics

AI is the “brain” of the modern supply chain. It is being applied to everything from demand forecasting to inventory optimization. Traditional forecasting methods often rely on historical data, which can be less effective during a major market shift. AI, however, can ingest real-time signals like weather patterns, social media trends, and macro-economic shifts. This leads to more accurate inventory targets, reducing the risk of both stockouts and overstocking.

In the world of logistics, AI helps with dynamic rerouting. If a storm is brewing or a port is congested, AI can suggest the best alternative path before the delay even happens. Data from industry surveys shows that a large majority of tech and telecom leaders believe digital tools have improved their visibility into end-to-end costs. This level of insight allows for much more proactive decision-making.

IoT, Telematics, and Real-Time Visibility

If AI is the brain, the Internet of Things (IoT) is the “eyes and ears.” We are talking about sensors on shipping containers, GPS trackers on trucks, and smart shelves in warehouses. By 2025, tens of billions of IoT devices are expected to be connected globally. This creates a massive stream of real-time data about the location and condition of your goods. If a shipment of temperature-sensitive medicine gets too warm, you will know immediately, not when it arrives at the destination ruined.

This data feeds into your analytics dashboards, allowing you to spot bottlenecks you never knew existed. Maybe a specific warehouse dock is always 20% slower than the others. Or perhaps a certain carrier consistently misses their windows. Having this data at your fingertips allows you to fix small problems before they become big, expensive disasters.

Automation and Robotics

We mentioned robotics earlier, but it is worth a closer look. Automation is moving beyond simple repetitive tasks. We now have collaborative robots (cobots) that work alongside humans and autonomous mobile robots (AMRs) that navigate warehouses on their own. Robotic Process Automation (RPA) is also huge for the “office” side of the supply chain. It can automate invoicing, order entry, and documentation, freeing your staff from tedious data entry.

This is particularly important because of the persistent labor shortages we are seeing globally. When you cannot find enough people to staff a warehouse, robots can fill the gap. They don’t get tired, they don’t take breaks, and they are incredibly precise. This leads to higher throughput and lower error rates, which is a win for everyone involved.

Your Practical Roadmap for Implementation

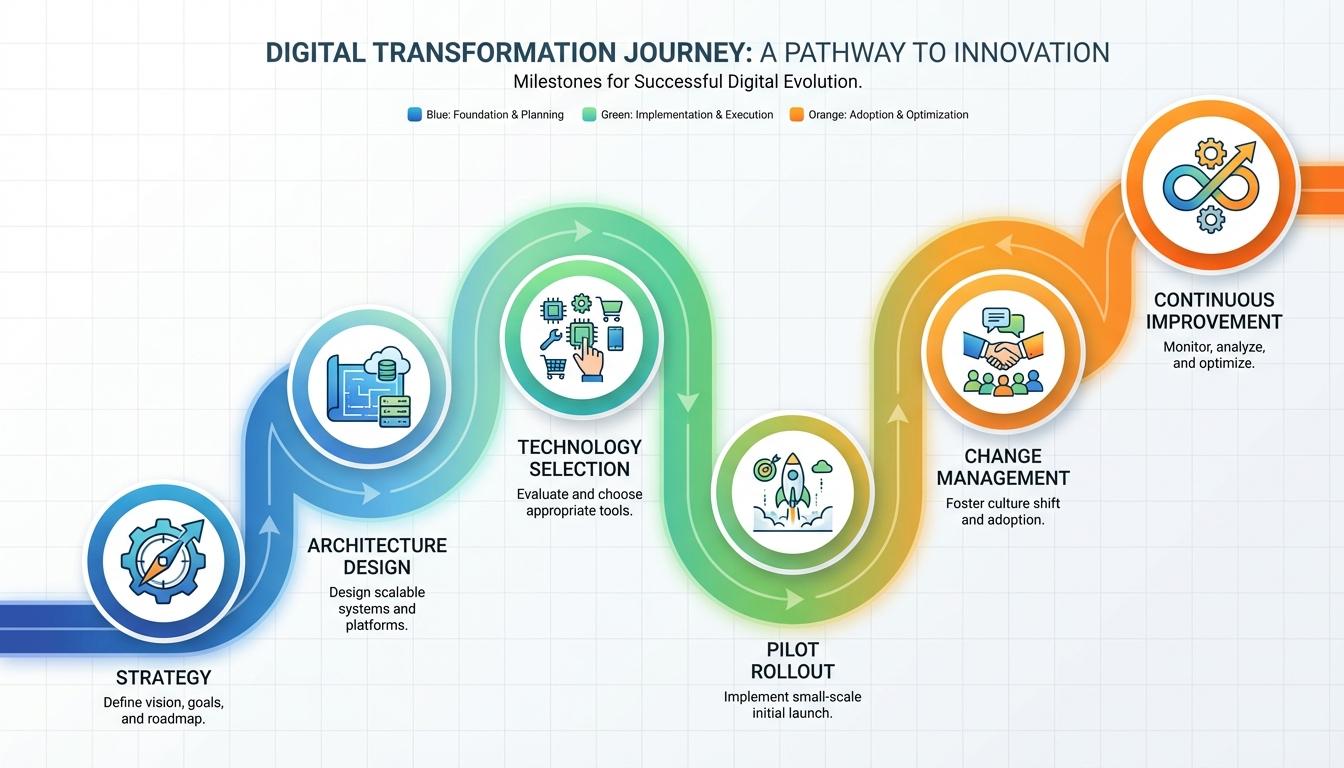

So, how do you actually get started? We have found that the most successful implementations follow a very structured lifecycle. Jumping straight into a software purchase is a recipe for frustration. You need a plan. Let us break down the steps that will lead you to success.

- Strategy and Business Case: Start by asking what problem you are trying to solve. Are you trying to reduce costs? Improve service? Increase resilience? Align your tech goals with specific business outcomes. Conduct a maturity assessment to see where you are and where you need to be.

- Use-Case and Architecture Design: Define exactly how the technology will be used. Will you use AI for forecasting? Will you integrate your TMS with your carriers? Design a target architecture that shows how your new tools will talk to your existing systems, like your ERP.

- Technology Selection and Vendor Management: This is where you go shopping. Look for solutions that are scalable and integrate well with others. For a deeper look at what to look for in a warehouse system, check out our guide on WMS selection criteria and features. It will help you ask the right questions during vendor demos.

- Pilot, Rollout, and Scaling: Do not try to change everything at once. Start with a pilot at one site or on one shipping lane. This allows you to work out the kinks in a controlled environment. Once you have proven it works, you can gradually expand to the rest of the organization.

- Change Management and Skills: This is the most important part, and the part most people skip. Your people need to be trained on the new systems, and you need to manage the cultural shift. Technology is only as good as the people using it.

- Continuous Improvement: The work is never really “done.” Use the data your new systems generate to constantly refine your processes. Cloud platforms make it easy to add new features and updates without a massive overhaul.

If you are looking for specific advice on moving goods, for more information on the transport side, see our TMS implementation guide. It provides a more granular look at the logistics side of this roadmap.

The Human Element: Change Management and Skills

Let us be real for a moment. Most technology projects do not fail because the software is bad. They fail because the people using it were not prepared. Change is scary. Your team might worry that a new robot or AI tool is going to replace them. Or they might just be frustrated that the way they have done things for twenty years is changing. This is where leadership matters most.

You need to articulate a clear vision for why this change is happening. Show them how the technology will make their jobs easier or more interesting. Instead of spending all day on data entry, maybe they can now focus on solving complex supplier issues. Invest in digital literacy and data skills across the whole company. When your team feels empowered by the tech rather than threatened by it, the results are much better.

Governance is also key. You need clear ownership of the digital transformation. Who is responsible for the data quality? Who makes the final call on which tools to buy? Without strong governance, you end up with “random acts of digital” where different departments buy their own tools that don’t talk to each other. This creates the very silos you were trying to break down in the first place.

The Real Benefits of Getting It Right

When you successfully implement the right technology, the rewards are significant. It is not just about a few percentage points of efficiency. It is about transforming your competitive position in the market. Here is what you can expect when you get it right.

- Dramatic Efficiency Gains: Automation and optimized workflows mean you can do more with less. This lowers your operating costs and frees up capital that was previously tied up in excess inventory.

- Unmatched Visibility: You will finally have a single view of your entire network. You can see orders, inventory, and shipments in real-time. This allows for much faster, data-driven decision-making.

- Higher Customer Satisfaction: Better forecasting and real-time tracking mean more on-time deliveries. When you can tell a customer exactly when their package will arrive, and then actually hit that window, you build incredible loyalty.

- Improved Resilience: With better scenario planning and supplier monitoring, you can react to disruptions in hours rather than days. This can save your business millions during a major crisis.

- Easier Compliance: Automated record-keeping makes ESG reporting and regulatory compliance much less of a headache. You have an auditable trail for every product you sell.

The good news is that these benefits are within reach for companies of all sizes. Cloud-based tools have leveled the playing field, allowing smaller players to access the same powerful analytics and automation as the global giants. You do not need a billion-dollar budget to start your digital journey.

Common Challenges and How to Avoid Them

We would not be doing our job if we didn’t mention the pitfalls. Implementation is hard work, and there are several common ways things can go wrong. Being aware of these challenges is the first step toward avoiding them. What we found is that most failures stem from a few recurring issues.

Integration and Data Silos

This is a big one. If you buy a great new TMS but it doesn’t talk to your ERP or your warehouse system, you have just created another data silo. You won’t get that end-to-end visibility you are looking for. Integration must be a priority from day one. Look for tools that have robust APIs and are designed to work in a connected ecosystem. Don’t settle for “point solutions” that operate in a vacuum.

Balancing the Short-Term and Long-Term

Nearly three-quarters of operations leaders say they struggle to balance immediate daily pressures with long-term digital change. It is hard to focus on a new software rollout when you are dealing with a port strike or a major supply shortage. However, the leaders who succeed are the ones who treat digital transformation as a strategic priority, not a side project. You have to make space for it, even when things are busy.

Cybersecurity Risks

As you connect more of your systems to the cloud and the IoT, your attack surface increases. Cybersecurity is not just an IT problem. It is a supply chain problem. A single breach at a supplier could shut down your entire production line. You must invest in robust security frameworks and make sure your partners are doing the same. Trust is the currency of the digital supply chain, and a cyber attack can bankrupt that trust overnight.

Trends Shaping the Future Through 2025

As we look toward 2025, the pace of change is only going to accelerate. AI is moving from a “nice to have” to the core of every major supply chain investment. However, there is still a massive opportunity here. Surveys show that a large share of organizations have not yet fully integrated AI into their operations. If you start now, you are still ahead of the curve.

We are also seeing a massive shift toward “sustainability by design.” Technology is being used not just to optimize for cost, but to optimize for carbon footprint. This is no longer just about PR. It is about meeting real regulatory mandates and customer demands for ethical supply chains. Traceability tools like blockchain will become more common for verifying the origin and sustainability of materials.

Finally, expect to see even more focus on “operator-assist” technologies. These are tools that help human workers do their jobs better, rather than replacing them. Think augmented reality glasses that help warehouse workers find items faster, or AI “co-pilots” that help planners make better decisions. The future of the supply chain is a partnership between human intelligence and machine efficiency.

Frequently Asked Questions

What is the difference between implementation and transformation?

Great question. Implementation is the act of putting a specific tool in place, like a new piece of software. Digital supply chain transformation is much broader. It involves changing your entire business model, your culture, and your processes using technology as the catalyst. You can implement a tool without transforming your business, but you cannot transform your business without implementing the right tools.

Which technology should we prioritize first?

This comes up a lot, and the answer depends on your specific pain points. However, for most companies, the foundations are cloud-based platforms and real-time visibility tools. You need a solid data foundation before you can successfully use advanced AI or robotics. Start by getting your data out of silos and into a format you can actually use to make decisions.

How do we measure the ROI of these projects?

You want to look at both financial and operational KPIs. Financial metrics include things like reduced inventory carrying costs and lower shipping expenses. Operational metrics include improved forecast accuracy, higher on-time delivery rates, and reduced lead times. Don’t forget to track “soft” benefits like improved employee retention and better supplier relationships, which have huge long-term value.

What if my team resists the new technology?

This is a very common challenge. The key is communication and training. Involve your team early in the process so they feel a sense of ownership. Show them how the tech will help them, and provide plenty of support as they learn the new systems. When people see that the technology makes their workday less stressful, the resistance usually fades away.

Is AI really ready for the supply chain?

Absolutely. While the hype can be overwhelming, the practical applications of AI in demand forecasting and logistics optimization are very real and delivering significant value today. The trick is to start with a specific use case rather than trying to “AI everything” at once. Focus on a problem where you have good data and a clear goal.

Wrapping It All Up

We have covered a lot of ground together. From the basic definitions of supply chain technology implementation to the advanced world of AI and IoT, it is clear that the landscape is changing fast. The most important thing to remember is that you are not just buying software. You are building a more resilient, efficient, and responsive business for the future. It is a journey, and it is okay to take it one step at a time.

What we found is that the companies that succeed are the ones that keep their eyes on the prize. They don’t get distracted by every new shiny gadget. Instead, they focus on the tools that solve their biggest problems and deliver real value to their customers. They invest in their people as much as their tech, and they aren’t afraid to adapt as the world changes around them.

Now you have the knowledge and the roadmap to start your own transformation. The next step? Pick one area where your supply chain is struggling and look at how a digital solution could help. You have got this. Whether it is improving your warehouse flow or getting better visibility on your shipments, the right technology can make all the difference. Are you ready to build the supply chain of the future?