Creating a Packing List for Smooth Customs Clearance

Looking for the exact breakdown of how to create a packing list for customs? You have come to the right place. While general guides cover the basics, you need the specific details that actually help you navigate the complexities of international trade without getting stuck in a port. We are going to get straight into what works, what does not, and exactly what you should do to ensure your cargo moves across borders smoothly. Let us get specific.

If you are reading this, you probably already know that shipping goods internationally requires more than just a box and a label. You are looking for the detailed breakdown of this specific document, not a general overview. This is one of those areas where getting it right makes a real difference. A single error in weight or a vague description can trigger an inspection that delays your shipment for weeks. We have seen this question come up constantly, so let us settle the requirements once and for all.

What Exactly Is a Packing List for Customs?

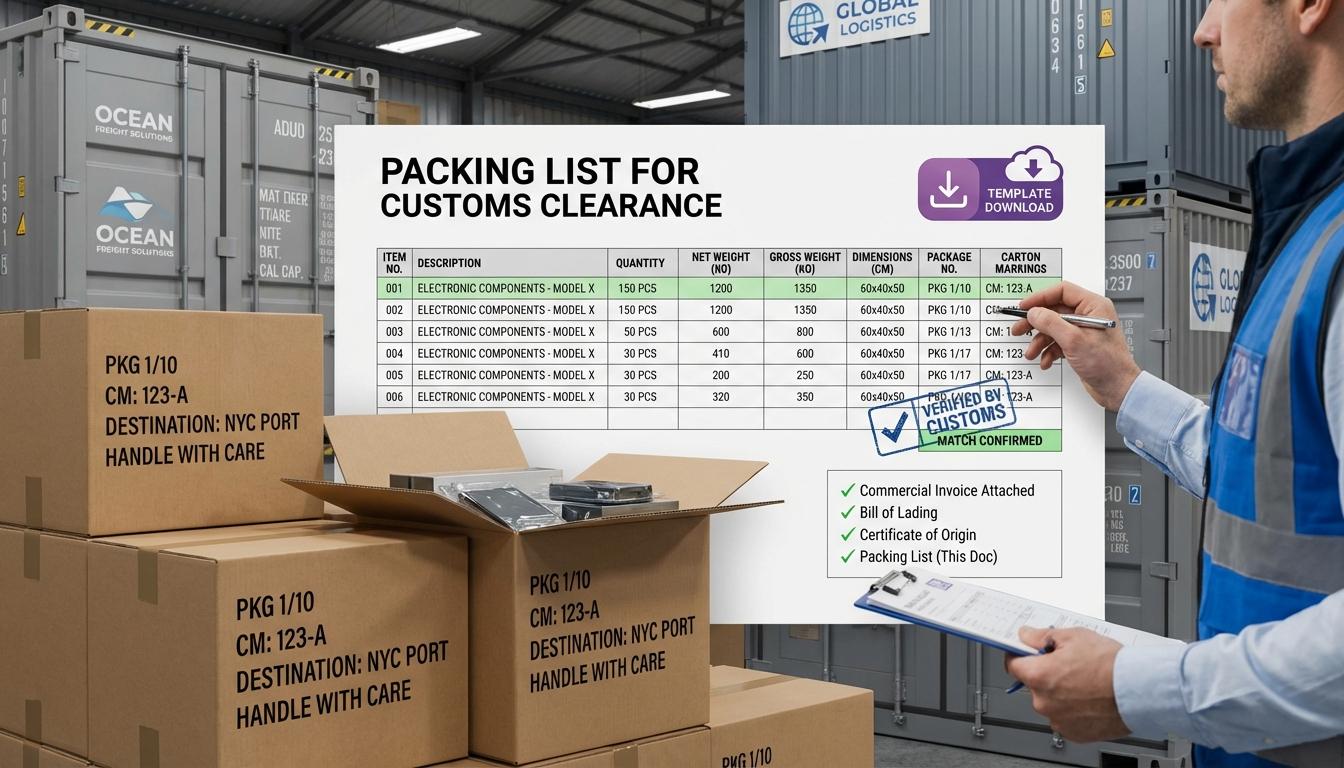

The export packing list is a formal document prepared by the shipper that itemizes every single item within a shipment. It is a technical map of your cargo. It tells customs officials, freight forwarders, and warehouse staff exactly what is inside each box, pallet, or container. Unlike other documents that focus on money, this document focuses on the physical reality of the goods. It tracks the composition, quantity, and weight of everything you are sending.

Here is the specific answer regarding its purpose. Customs authorities use this list to verify that the physical contents of your shipment match what you declared on other forms. It is their primary tool for spot-checking. If they decide to open “Box 4 of 10,” they expect to find exactly what your packing list says is in that specific box. If there is a mismatch, you are looking at fines, delays, or even seizures. The document also helps freight forwarders calculate shipping costs and plan space on planes or ships.

So what does this mean for you? It means your cargo packing list must be incredibly precise. We are not just talking about a general list of items. We are talking about a package-by-package breakdown. This document serves as the foundation for your shipping insurance and claims as well. If something goes missing, the packing list is the first piece of evidence used to prove what was originally loaded into the container. It is your best defense against logistics errors.

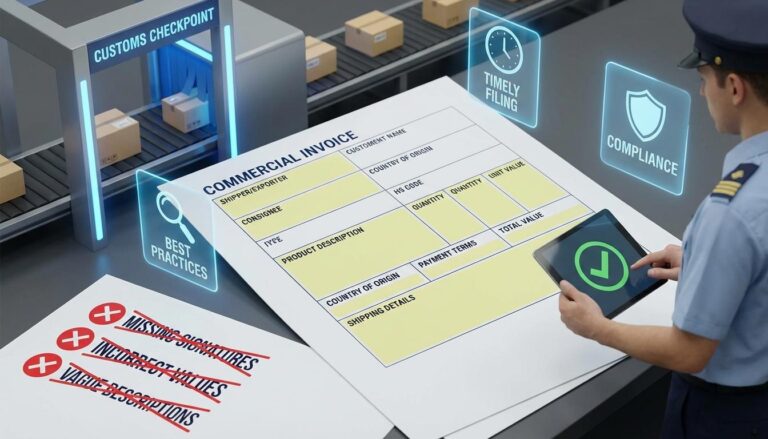

The Critical Difference Between a Packing List and a Commercial Invoice

The real question is why you need both a packing list and a commercial invoice. Many new exporters assume these documents are redundant. They are not. The key difference is the type of information they prioritize. A commercial invoice is a financial document. It focuses on the transaction value, payment terms, and the parties involved. It is used to determine how much duty and tax you owe.

In contrast, the shipping packing list is a logistics document. It ignores the prices and focuses on the physical dimensions and weight. While the descriptions of the goods must match perfectly between the two documents, the packing list adds layers of detail about the packaging itself. For example, the invoice might say you are shipping 1,000 widgets. The packing list will explain that those 1,000 widgets are packed into 20 cartons, which are stacked on 2 wooden pallets, each weighing 250 kilograms. For a more detailed look at the financial side of these requirements, you can read our commercial invoice shipping guide to understand how these two documents work together.

Here is the thing most people miss. Customs officials often look at the packing list first when they decide which shipments to inspect. If the packing list is vague or poorly organized, it raises a red flag. They want to see professional, detailed documentation that makes their job easier. If your packing list is crystal clear, they are more likely to process your shipment quickly. This is where your best move is to ensure that every SKU and quantity on your invoice aligns perfectly with the totals on your packing list.

Core Customs Packing List Requirements

Let us look at this closely. To satisfy international customs packing list requirements, you cannot just scribble a list on a piece of paper. You need a structured format that includes specific data fields. Most modern customs authorities, including those in the United States and the European Union, look for a standardized set of information. If you omit any of these, you are essentially asking for a delay.

The following elements are mandatory for a compliant document:

- Shipper and Consignee Information: You must include the full legal name, address, and contact details for both the person sending the goods and the person receiving them.

- Reference Numbers: This includes the commercial invoice number, the purchase order number, and the date of the shipment. These link the documents together in the customs system.

- Transport Details: Mention the mode of transport, whether it is air, ocean, road, or rail. If you have a container number or seal number, include it here.

- Total Shipment Summary: A clear statement of the total number of packages, total gross weight, and total net weight.

- Itemized Descriptions: Avoid generic terms. Instead of “clothing,” use “Men’s 100% Cotton T-Shirts.”

- HS Codes: The Harmonized System codes are vital for classification. They tell customs exactly what the product is in a universal numerical language.

- Country of Origin: You must specify where the goods were manufactured for each line item.

The practical takeaway is that consistency is king. If your invoice says “Origin: Vietnam” and your packing list says “Origin: Thailand,” your shipment will be flagged. This often happens when companies use different templates for different departments. Your next step is to create a unified system where this data is pulled from the same source to prevent human error. If your shipment involves complex trade agreements, you might also need a certificate of origin to support your claims on the packing list.

Detailed Package-Level Information: The Secret to Smooth Clearance

Now for the part you actually came here for. A detailed packing list goes beyond just listing the totals. The most effective documents provide a per-package breakdown. This is exactly what customs inspectors need when they decide to look inside your shipment. They don’t want to dig through twenty pallets to find one specific item. They want to know exactly which pallet contains it.

Here is the step-by-step breakdown of how to list package details:

- Package Numbering: Label your boxes clearly (e.g., Box 1 of 10, Box 2 of 10). Your packing list should reflect these exact numbers.

- Packaging Type: Specify if it is a carton, a crate, a drum, or a pallet. This helps handlers know how to move the cargo safely.

- Dimensions: Include the length, width, and height for every package. This is used to calculate the “volumetric weight,” which often determines your shipping costs.

- Net vs. Gross Weight: Net weight is the weight of the product alone. Gross weight includes the product, the packaging, and the pallet. Customs needs both to verify the accuracy of the shipment.

- Shipping Marks: These are the symbols or text printed on the outside of the boxes. Include them on the list so inspectors can match the document to the physical box in front of them.

This is the detail that changes everything. When you provide a per-package breakdown, you demonstrate total control over your supply chain. It shows that you know exactly what you are shipping and how it is organized. According to the International Trade Administration, providing this level of detail is a recommended best practice that significantly reduces the likelihood of intrusive inspections. For a broader look at the entire paperwork process, check out our main guide on the international shipping documents checklist.

Quick Reference: Packing List at a Glance

For those who want a fast version of what we have covered, here is a scannable summary of the essentials. Use this as a final checklist before you hit print on your next shipment.

- Document Title: Must be clearly labeled as “Packing List” or “Export Packing List.”

- Language: Use English or the language required by the destination country’s customs office.

- Consistency: Quantities and HS codes must match the Commercial Invoice exactly.

- Weights: Always include both Net Weight and Gross Weight in kilograms or pounds.

- Measurements: Dimensions for every individual box or pallet.

- Accessibility: One copy on the outside of the lead package (in a clear pouch) and one copy inside.

- Specifics: List every SKU and the specific box it is located in.

Quick reality check here. Many people think they can just use a standard packing slip international buyers receive in their e-commerce packages. Those slips usually only list the items. They rarely include weights, dimensions, or HS codes. For customs purposes, a simple packing slip is not enough. You need the full technical detail of an export packing list to avoid complications.

Best Practices for Creating a Compliant Document

Let us get into the details of how to actually execute this. We have discussed what goes on the document, but how you present it matters just as much. The goal is to make the information as easy to digest as possible for a busy customs agent. If they have to hunt for information, they are more likely to get frustrated and order a manual inspection.

First, use a professional template. Do not try to reinvent the wheel. A standard layout with clear headers and a grid-based table for the items is the industry standard. Most ERP or shipping software will generate this for you, but you must ensure the data being fed into it is accurate. Second, use clear, unambiguous language. Avoid internal company jargon or abbreviations that an outsider wouldn’t understand. If you sell “Blue Sky Ultra Widgets,” call them that, but also include a descriptive category like “Industrial Plastic Fasteners.”

Third, handle special cargo with extra care. If you are shipping hazardous materials, your packing list must reference the Dangerous Goods declaration. If you are shipping pharmaceuticals, include the storage temperature requirements. According to FedEx, including these references on the packing list is essential for the safety of the handlers and for regulatory compliance. The action item here is simple. Review your template today. Does it have a dedicated section for special handling instructions? If not, add one.

Common Errors That Cause Customs Delays

Even experienced shippers make mistakes. The most common error is a mismatch in weight. If your packing list says the shipment weighs 500kg, but the carrier’s scale says 550kg, customs will immediately suspect that you are trying to smuggle undeclared goods. Always weigh your shipment after it is fully packed and palletized to get an accurate gross weight.

Another frequent mistake is “lumping” items together. For example, if you are shipping 50 different types of replacement parts, do not just list “50 Spare Parts.” You must list each part type, its quantity, and its specific HS code. Vague descriptions are the fastest way to get your shipment stuck in a warehouse. Also, watch out for missing shipping marks. If your list says “Box A,” but the boxes are not labeled “Box A,” the inspector has no way to verify the contents without opening every single box.

Finally, do not forget the “Box 1” rule. Best practice is to place a copy of the packing list inside the very first box and another copy in a clear waterproof envelope on the outside of that same box. This ensures that even if the external paperwork is torn off during transit, the warehouse staff or customs officials can still identify the contents. Ready for the specifics? Double-check your next shipment against these errors before it leaves your dock.

Common Questions About Packing Lists for Customs

Is a packing list legally required for every shipment?

The answer is that while some countries do not strictly mandate it for every small parcel, it is treated as a requirement by almost all freight forwarders and customs brokers. Without it, they cannot accurately prepare the Bill of Lading or the customs entry. In practice, you should consider it mandatory for any international commercial shipment.

Can I just use my commercial invoice as a packing list?

Not quite. While a commercial invoice contains some of the same information, it lacks the package-level details, weights, and dimensions that are required for logistics. Customs officials expect two separate documents. Using one for both purposes is a risky move that often leads to delays.

What if I don’t know the exact weight of each box?

You need to find out. Guestimates are not acceptable in international shipping. If you do not have an industrial scale, you must work with your logistics provider to get accurate weights before the customs documentation is finalized. Accuracy is the only way to ensure smooth clearance.

Do I need to list the value of the items on the packing list?

No, you generally do not need to list prices or total values on the packing list. That information belongs on the commercial invoice. The packing list is strictly for physical descriptions, quantities, and weights. Keeping the financial data on the invoice helps keep the packing list clean and focused on logistics.

Final Takeaways for Seamless Shipping

Creating a packing list for customs does not have to be a headache if you approach it with a focus on detail and consistency. The short version is that this document is your shipment’s physical identity. It tells the story of what you are shipping, how it is packed, and how much space it occupies. When you get this right, you reduce the friction in your supply chain and build a better relationship with customs authorities.

Remember that the details matter. Ensure your HS codes are accurate, your weights are verified, and your package numbering is clear. If you provide a detailed, package-by-package breakdown, you are light years ahead of most shippers. Your next action is to audit your current shipping process. Are your packing lists truly “customs-ready,” or are they just basic slips? Spend the extra ten minutes to get the data right now, and you will save yourself ten days of delays later.