ABC Inventory Classification: Prioritizing What Matters Most

Are you spending the same amount of time managing a five-cent bolt as you do a five-thousand-dollar engine? If so, your warehouse efficiency is taking a hit. Using ABC inventory classification is the most effective way to separate the vital few from the trivial many. We are going to show you exactly how to rank your stock so you can focus your energy where the money actually is. This is not just about organizing shelves. It is about protecting your cash flow and ensuring your most important customers never see an “out of stock” notice.

You probably already know that not all inventory is created equal. Some items fly off the shelves, while others gather dust for months. The mistake most managers make is trying to apply a “one size fits all” strategy to every SKU in the building. We are here to provide the detailed breakdown you have been searching for to fix that. This specific method allows you to stop guessing and start using data to drive your warehouse operations. Let us get into the details.

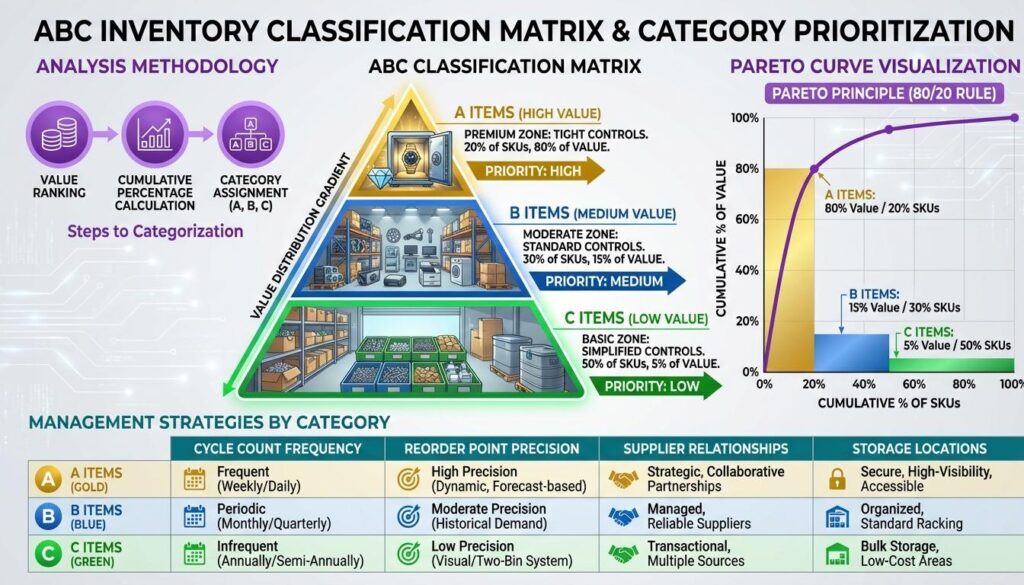

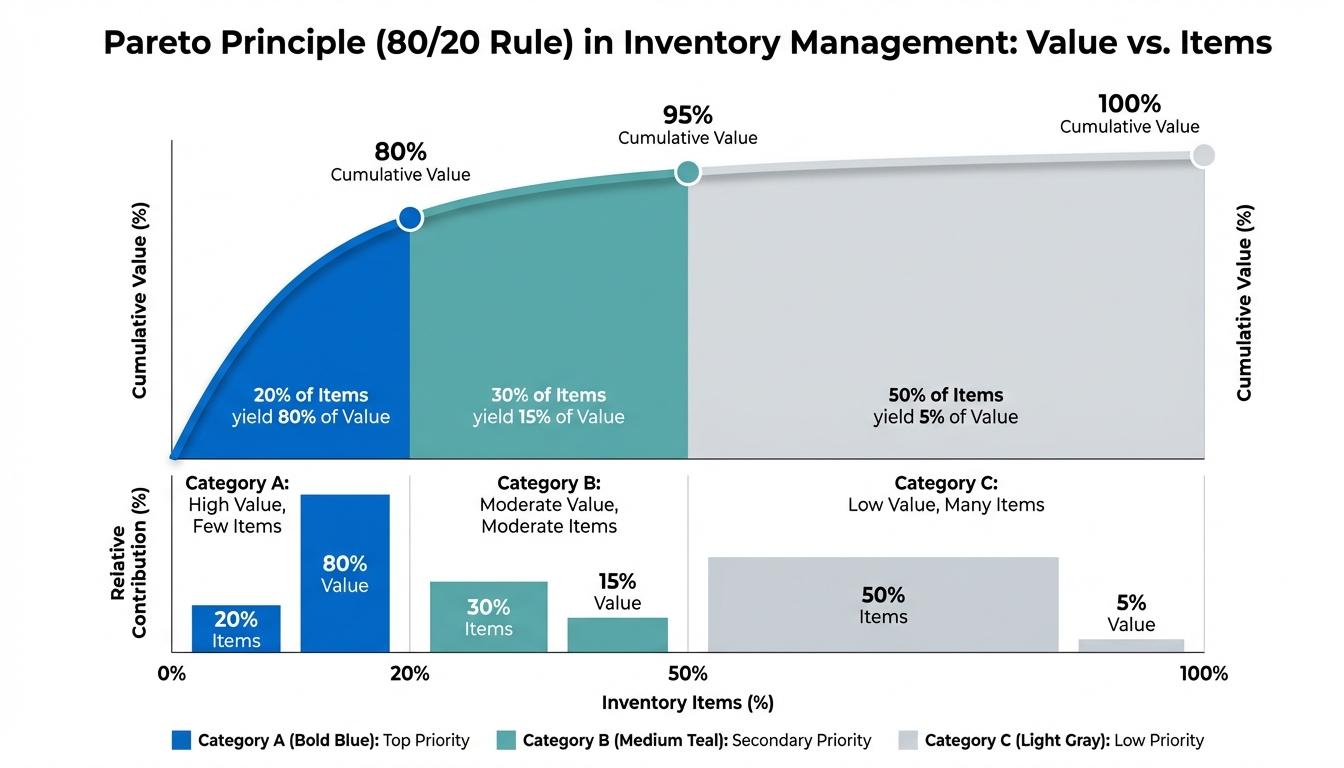

The Mechanics of the 80/20 Rule in Inventory

The foundation of ABC inventory classification is the Pareto Principle. This principle suggests that 80 percent of your results come from 20 percent of your efforts. In the world of logistics, this usually means that 80 percent of your revenue or consumption value is driven by just 20 percent of your items. We call these your “Category A” items. Understanding this ratio is the first step toward regaining control over your warehouse. It allows you to stop treating every item as equally important.

When we apply this logic, we categorize stock into three distinct buckets. Category A represents the high-value items that require the most attention. Category B includes the moderate-value items that keep the business steady. Category C covers the low-value items that make up the bulk of your physical SKU count but very little of your financial value. The goal is to align your management efforts with the actual financial impact of the goods. For a complete overview of how this fits into your broader operations, check out our main guide on best inventory management methods.

So what does this mean for you? It means you can stop stressing over the tiny details of every single product. Instead, you can focus 80 percent of your analytical brainpower on the 20 percent of items that actually pay the bills. This shift in perspective is what separates elite supply chain managers from those who are constantly putting out fires. Here is the thing most people miss: if you treat everything as a priority, then nothing is a priority.

Breaking Down Category A: The Vital Few

Category A items are the crown jewels of your inventory. These typically represent about 10 to 20 percent of your total SKUs but account for a staggering 70 to 80 percent of your total inventory value or revenue. Because these items have such a massive impact on your bottom line, they demand the tightest possible control. You cannot afford to lose track of these. Even a small discrepancy in Category A counts can lead to massive financial losses or major production delays.

How do we manage these high-stakes items? First, they need frequent monitoring. We recommend daily or weekly cycle counts for Category A items rather than waiting for an annual physical inventory. You should also keep these items in the most accessible parts of your warehouse. Put them near the shipping docks or at eye level on the racks to minimize travel time and handling. This is where getting it right makes a real difference. Since these items move fast or cost a lot, every second saved in picking them adds up to significant labor savings.

Your best move here is to maintain very precise records. We often see companies keep higher safety stocks for these items to avoid stockouts, but this requires a delicate balance. If you want to get the math right for these critical products, you should look into safety stock calculation formulas to ensure you are protected without tying up too much cash. The key difference for Category A is the level of human oversight. These items should be reviewed by your best planners regularly.

Category B and C: The Moderate and the Bulk

Category B items are the middle child of inventory. They usually make up about 30 percent of your SKUs and contribute roughly 15 to 20 percent of your value. They are important, but they do not require the constant, eagle-eyed supervision that Category A items do. We generally treat these with moderate control. This means periodic reviews and less frequent cycle counts. You might count these once a month or once a quarter. They are the “steady” part of your business that requires a balanced approach to ordering and storage.

Then we have Category C. This category is often the largest in terms of sheer volume, typically making up 50 to 70 percent of your SKUs. However, they only account for about 5 percent of your total value. These are the nuts, bolts, packaging materials, or slow-moving accessories. While you do not want to run out of them, spending hours analyzing their demand patterns is a waste of your time. Let us get specific here. For Category C items, the cost of managing the inventory can sometimes exceed the value of the items themselves. That is a trap you want to avoid.

The strategy for Category C is simple: automate it and forget it. Use relaxed controls and less accessible storage areas. You can store these on the highest racks or in the back of the warehouse. Since they are low value, you can often afford to order them in bulk to take advantage of volume discounts. This is where economic order quantity guide principles become very useful. By ordering larger quantities of C items less often, you reduce administrative costs and free up your team to focus back on Category A.

Choosing Your Classification Criteria

The real question is how you actually decide which item goes into which bucket. Most businesses use “Annual Usage Value,” which is the unit cost multiplied by the number of units used or sold in a year. This is the most common method because it directly relates to your cash flow. If an item costs $100 and you sell 1,000 a year, its value is $100,000. If another item costs $1 and you sell 5,000, its value is only $5,000. The $100 item is clearly the Category A priority here.

However, usage value is not the only way to play this. You can also classify by:

- Rotation Frequency: How often is the item picked? High-velocity items might be Category A even if they are cheap, simply because they drive so much warehouse activity.

- Unit Cost: Extremely expensive items might be Category A regardless of how often they move, simply because of the financial risk involved in storing them.

- Lead Time: Items that take six months to arrive might be bumped up a category because a stockout would be catastrophic.

- Criticality: If a specific $2 part is the only thing that keeps a million-dollar machine running, you might treat it as a Category A item.

Your best approach is often a combination of these. According to research on Pareto Principle applications, focusing on the “vital few” is the most universal way to improve efficiency. We recommend starting with usage value as your primary metric and then adjusting for specific strategic needs. The practical takeaway is to pick the metric that aligns with your biggest headache. Is it lost revenue? Then use sales value. Is it warehouse congestion? Then use pick frequency.

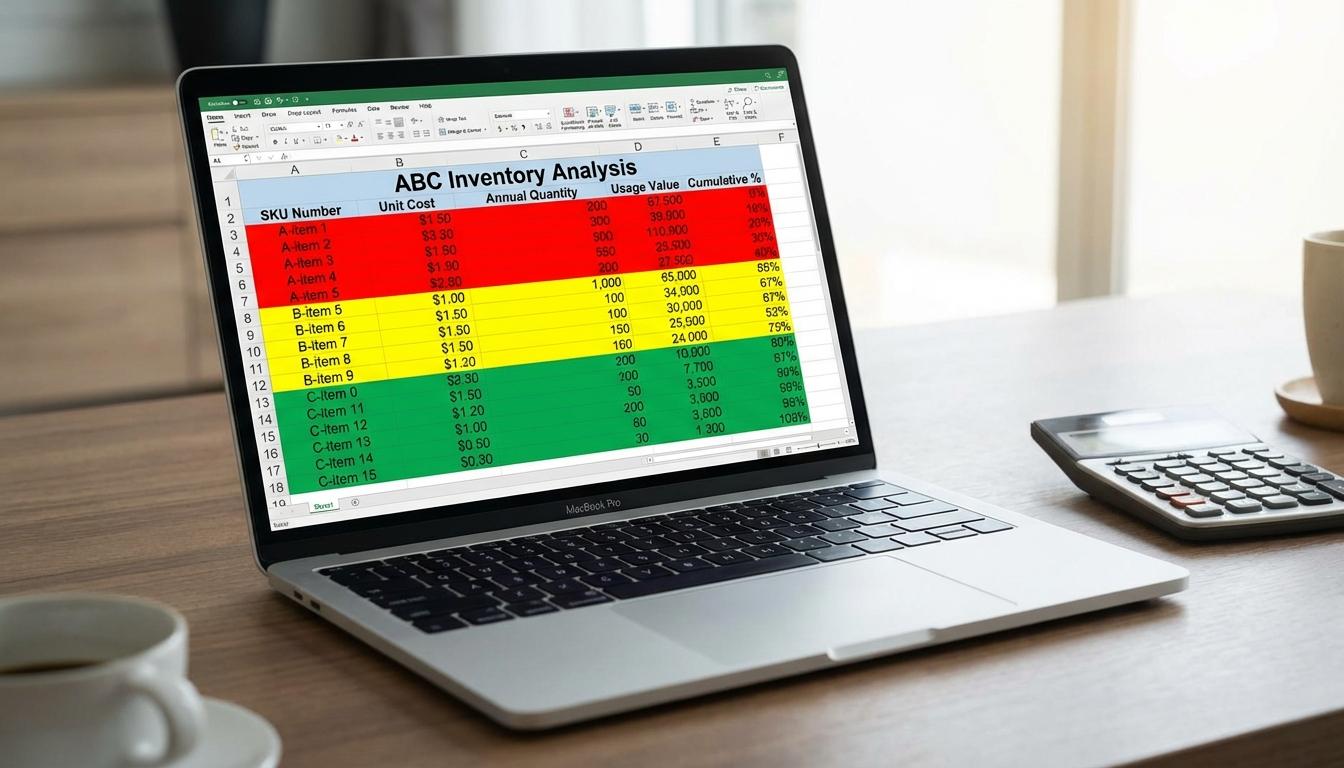

Step-by-Step Guide to Calculating ABC Categories

Ready for the specifics? Follow this step-by-step breakdown to categorize your current stock. You will need your inventory list, unit costs, and the last 12 months of demand data. If you have a modern warehouse management system, it might do this for you, but knowing the manual process is vital for checking the accuracy of the data.

- List every SKU: Start with a clean spreadsheet of all your active items.

- Calculate Annual Usage Value: Multiply the number of units sold or used by the unit cost for each SKU.

- Sort in descending order: Rank your list from the highest usage value at the top to the lowest at the bottom.

- Calculate cumulative totals: Add up the total value of all items combined. Then, create a running total as you go down your sorted list.

- Determine percentages: Calculate what percentage of the total value each item represents. Then, calculate the cumulative percentage of the total value as you move down the list.

- Assign Categories: Stop when you hit the 80 percent mark of the total value. Those top items are Category A. The next 15 percent of value represents Category B. The final 5 percent of value represents Category C.

This is the detail that changes everything. Once you see the percentages on paper, the disparity is usually shocking. You will likely find that a handful of items are doing all the heavy lifting for your business. The action item here is simple. Take that list and share it with your warehouse team. Make sure they know which items are the priorities starting tomorrow morning. When everyone knows what the Category A items are, the entire culture of the warehouse shifts toward protecting those assets.

Practical Applications and Inventory Control Strategies

Now for the part you actually came here for. How do you use these classifications to change your daily operations? It starts with your physical layout. We have seen warehouses slash their picking times by 30 percent just by moving Category A items closer to the packing stations. If your pickers are walking to the back of the building for your most popular items, you are burning money every single hour.

Purchasing strategy is another huge area of impact. For Category A items, you should consider just-in-time (JIT) deliveries or frequent, smaller orders to keep your cash fluid. For Category C items, do the opposite. Order them twice a year in bulk. This reduces the number of purchase orders your team has to process and the number of deliveries your receiving dock has to handle. Research from Oracle’s supply chain experts suggests that tailoring these controls can reduce carrying costs by up to 20 percent.

Cycle counting is the third pillar of this strategy. Instead of counting everything once a year, count your Category A items every week. Count Category B items every month. Count Category C items once or twice a year. This ensures that your most valuable data is always accurate. If a Category C item is off by five units, it might cost you two dollars. If a Category A item is off by five units, it could cost you ten thousand dollars. Focus your auditing where the risk is highest.

Challenges and How to Overcome Them

This is one of those areas where getting it right makes a real difference, but it is not without hurdles. The biggest trap is the static nature of the analysis. Markets change. Seasonality happens. A Category C item during the winter might become a Category A item in the summer. If you set your classifications once and never look at them again, you are going to run into trouble. We recommend a quarterly review of your ABC stratification to account for shifting demand patterns.

Another challenge is the “New Item” problem. New products do not have historical data, so they often default to Category C. This is a mistake. If you are launching a new product that you expect to be a bestseller, you must manually assign it to Category A from day one. You have to be proactive. Do not wait for the data to tell you what your business strategy already knows. Treat new launches with the same high-level control as your established winners until the data proves otherwise.

Lastly, do not forget the qualitative factors. Sometimes an item is Category C based on value but is strategically vital. Perhaps it is a part for a legacy machine that your biggest client still uses. In this specific situation, you might choose to upgrade that item to Category B just to ensure you never let that client down. Use the data as a guide, but do not let it replace your common sense. The practical takeaway is to use ABC analysis as a foundation, not a set of unbreakable laws.

Quick Reference: ABC Classification at a Glance

- Category A (High Value): ~20% of items, ~80% of value. Action: Strict control, frequent counts, prime storage.

- Category B (Moderate Value): ~30% of items, ~15% of value. Action: Moderate control, periodic review, middle storage.

- Category C (Low Value): ~50% of items, ~5% of value. Action: Loose control, bulk ordering, remote storage.

- Review Frequency: Quarterly or after major seasonal shifts.

- Primary Metric: Annual Usage Value (Unit Cost x Annual Quantity).

- Main Benefit: Optimized resource allocation and improved cash flow.

Common Questions About ABC Inventory Classification

What is the difference between ABC analysis and Pareto analysis?

The answer is that ABC analysis is a specific application of the broader Pareto Principle. While Pareto analysis can be used to study anything from customer complaints to wealth distribution, ABC analysis specifically focuses on categorizing physical inventory based on its financial impact or movement frequency.

How often should ABC classifications be reviewed?

We recommend reviewing your classifications at least once every quarter. However, if your business is highly seasonal, you might need to adjust them more frequently. For example, a retailer should definitely re-classify their stock before the peak holiday season to ensure high-demand items get the Category A treatment they deserve.

Can I use ABC classification for small businesses?

Yes, and you should. Small businesses often have even less time and fewer staff members, making prioritization even more critical. Even if you only have 50 SKUs, knowing which 10 are responsible for most of your profit allows you to manage your limited time much more effectively.

What happens if I ignore Category C items?

Not quite ignore, but rather “automate.” If you completely ignore them, you might run out of a tiny part that stops a whole production line. The goal is to use low-effort systems like two-bin kanban or simple reorder points so they take up zero mental energy while remaining in stock.

Should I use software for ABC inventory classification?

The short version is yes, especially if you have more than a few hundred SKUs. Most modern ERP and inventory management systems have built-in ABC modules that can recalculate categories in real-time. This saves you the headache of manual spreadsheet updates and ensures your categories are always based on the latest data.

Your next step is to pull your usage data for the last year and run a simple sort. You will likely see immediately where your time has been wasted and where your biggest opportunities for improvement lie. By implementing ABC inventory classification, you are not just organizing a warehouse. You are creating a focused, data-driven strategy that protects your most valuable assets while stripping away the noise of the “trivial many.” Start with your top 10 items today and see how much easier your inventory management becomes.