Cold Chain Logistics: Managing Temperature-Sensitive Supply Chains

Step back and see how a delicate piece of sashimi makes it from the cold waters of the Pacific to your plate in a landlocked city, still tasting fresh? Or how a life-saving vaccine manufactured in a high-tech lab in Europe reaches a remote clinic in a different climate without losing its potency? The answer lies in a complex, high-stakes world that most of us rarely think about until something goes wrong. We are talking about cold chain logistics, the invisible backbone of our modern world. It is the specialized process of managing the storage and transportation of products that must stay within a very specific temperature range from the moment they are made until the moment they are used.

We get it. At first glance, the idea of “temperature-controlled shipping” might sound like a dry topic reserved for warehouse managers and logistics experts. But here is the thing. Cold chain logistics is actually a feat of human engineering and coordination that affects almost every part of your daily life. If you have ever enjoyed a fresh salad in the middle of winter or relied on insulin to manage a health condition, you have the cold chain to thank. It is a world where minutes matter and a few degrees of temperature change can mean the difference between a safe product and a total loss.

In this guide, we are going to explore everything there is to know about this fascinating industry. We will look at how it started, the technology that keeps it running today, and the challenges that companies face when moving sensitive goods across the globe. Whether you are a business owner looking to optimize your supply chain or just someone curious about how the world works, we have you covered. Let us break this down together.

What Exactly is Cold Chain Logistics?

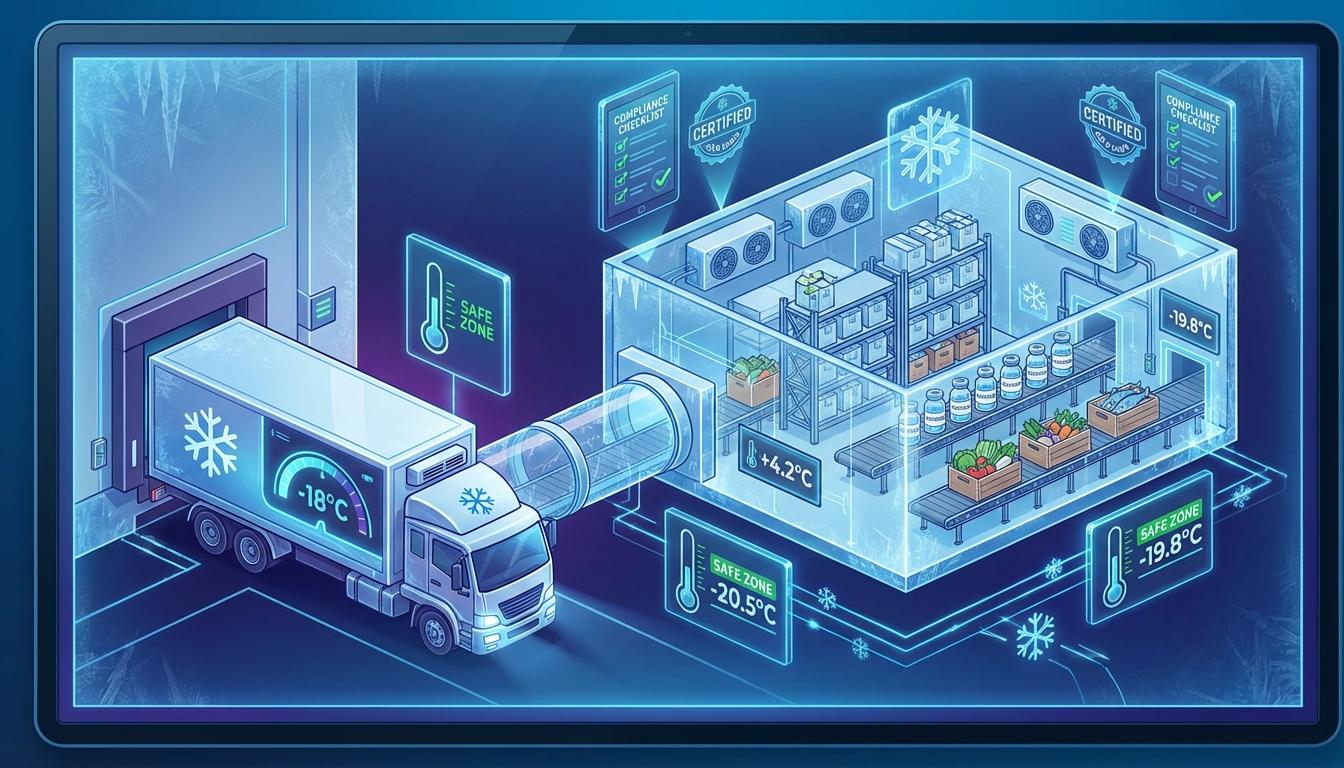

Let us start with the basics. In simple terms, cold chain logistics is a temperature-controlled supply chain. It is an unbroken sequence of refrigerated production, storage, and distribution activities. Every single link in this chain must be maintained at a specific temperature to preserve the quality and safety of the goods involved. If the temperature drops too low or rises too high, the chain is “broken,” and the product is often ruined.

What we found is that many people confuse simple refrigeration with a true cold chain. Here is the distinction. A cold chain is not just about keeping things cold. It is about precision. It involves a massive range of technologies including mechanical refrigeration, cryogenic cooling, and passive thermal packaging. It also requires constant monitoring. Unlike a standard supply chain where a delay might just mean a late package, a delay in the cold chain can lead to biological degradation or chemical changes that make a product dangerous to consume.

Core Concepts You Should Know

To really understand how this works, we need to look at a few key terms. You might hear people use “cold chain management” and “temperature-controlled logistics” interchangeably, but they often refer to different parts of the process. Cold chain management is the bird’s eye view. It includes the planning, the customs clearance, and the overall strategy. Cold chain logistics is the “doing” part. It is the actual movement and storage using reefers, cold rooms, and specialized packaging.

The goal is always the same. We are trying to maintain a “thermal profile.” This means if a vaccine needs to stay between 2 and 8 degrees Celsius, it stays in that window while it is on a plane, while it is in a truck, and while it is sitting in a warehouse. This is why time and temperature are the two most critical control parameters in the entire industry. They are the North Star for every logistics professional in this space.

The Fascinating History of the Cold Chain

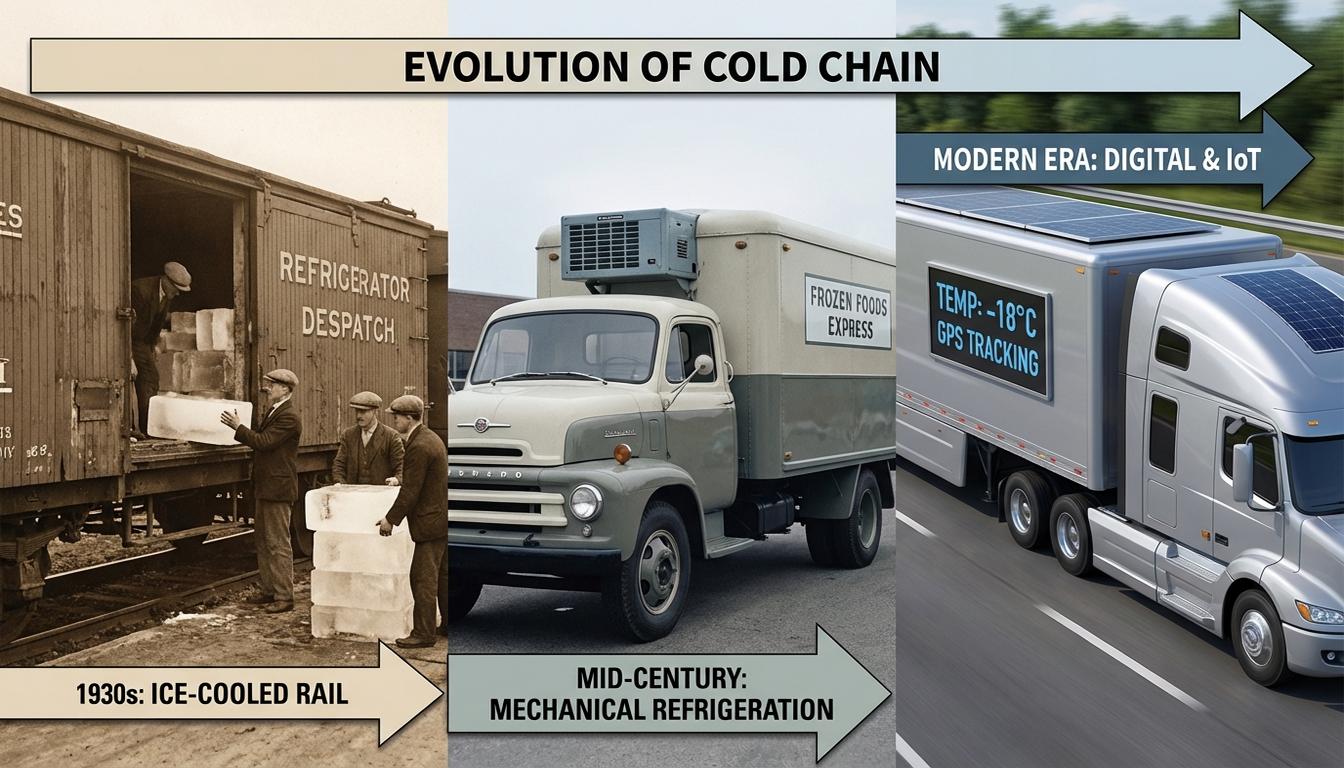

You might be surprised to learn that the cold chain is not a particularly new invention. While the high-tech sensors we use today are modern, the basic concept goes back centuries. Let us be real for a moment. Humans have always struggled to keep food fresh. In the late 18th century, British fishers were already using blocks of ice to preserve their catch while they were still at sea. This was one of the first documented versions of an organized cold chain.

By the mid-19th century, things started to accelerate. This was the era of the “ice trade.” People actually harvested natural ice from frozen lakes and transported it long distances to keep food cold. We saw the birth of “reefer ships” and refrigerator rail cars, which were basically giant iceboxes on wheels. Imagine the logistical nightmare of trying to move a train full of meat while praying the ice did not melt before you reached your destination. It was primitive, but it changed how the world ate.

The Turning Point: Mechanical Refrigeration

The real game-changer happened in the 1930s. An American inventor named Frederick Jones designed the first portable air-cooling unit for trucks. This was huge. For the first time, we did not need to rely on blocks of ice that were constantly melting. We could use mechanical refrigeration to maintain a steady temperature regardless of the weather outside. This technology was quickly deployed on trucks and railcars, making long-distance transport of perishables a reality.

During World War II, this technology became a matter of life and death. The military needed a way to move blood, medicines, and food to hospitals and battlefields across the globe. This pressure forced a rapid wave of innovation that eventually trickled down to the civilian world. By the 1950s, with the rise of the Interstate Highway System in the U.S., refrigerated trucking became the standard. This shift allowed for the birth of the modern supermarket where you can buy almost anything, at any time, regardless of the season.

What Products Rely on the Cold Chain?

When most people think of the cold chain, they think of the freezer aisle at the grocery store. While frozen pizza is a major player, the cold chain handles a much wider variety of goods than you might expect. Let us look at the heavy hitters.

Food and Agriculture

This is the biggest category. It includes fresh produce like fruits and vegetables, which need to stay cool to slow down the ripening process. Then you have dairy products like milk and yogurt, which can spoil in hours if left at room temperature. Meat, poultry, and seafood are also critical. For these items, the cold chain is not just about taste. It is about preventing the growth of harmful bacteria that cause foodborne illnesses. According to the Food and Agriculture Organization of the United Nations, a lack of proper cold chain infrastructure is one of the leading causes of food waste globally.

Pharmaceuticals and Healthcare

This is where the stakes are highest. Many modern medicines, especially vaccines and biologics, are extremely sensitive to heat. For example, insulin must be kept cool to remain effective. If a shipment of vaccines gets too warm during transport, the proteins can break down, rendering the vaccine useless. This is not just a financial loss. It is a public health crisis. During the global rollout of COVID-19 vaccines, the world saw a masterclass in ultra-cold chain logistics, where products had to be kept at temperatures as low as -70 degrees Celsius.

Chemicals and Specialty Goods

Here is something most guides do not mention. The cold chain is also vital for the chemical industry. Certain resins, specialty chemicals, and lab reagents are volatile or will degrade if they get too warm. Even things like photographic film and high-end cosmetics often require temperature control. If you have ever had a lipstick melt in a hot car, you can imagine what happens to a multi-million dollar shipment of industrial chemicals if the refrigeration fails.

How Cold Chain Logistics Actually Works

So, how do we actually move these things without breaking the chain? It is a coordinated dance between technology and process. Let us break this down into the stages that a product goes through.

1. Initial Cooling and Processing

The journey starts the moment a product is harvested or manufactured. For produce, this often involves “blast chilling” to remove the field heat immediately. For pharmaceuticals, it means moving the product directly from the production line into a temperature-controlled staging area. This first step is vital because it sets the baseline for the rest of the journey.

2. Cold Storage and Warehousing

Once cooled, products move to a cold storage facility. These are not just giant refrigerators. They are highly engineered environments with different “zones” for different products. Some areas might be kept at a crisp 2 degrees Celsius for dairy, while others are kept at -20 degrees for frozen goods. To learn more about how these facilities are built, you should look into our guide on cold storage warehouse design, which explains the engineering behind the insulation and airflow.

3. Specialized Packaging

This is where the “micro-logistics” happen. For smaller shipments, especially in the pharmaceutical world, we use thermal packaging. This might include vacuum-insulated panels, gel packs, or phase-change materials (PCMs) that absorb or release heat to maintain a steady temperature. This is essential for the “last mile” when a product might be sitting on a delivery porch or in a van that is frequently stopping and opening its doors.

4. Temperature-Controlled Transport

This is the most visible part of the chain. We use refrigerated trucks (reefers), ocean containers, and even specialized cargo holds in planes. These vehicles are equipped with their own refrigeration units and thick insulation. The trick here is not just keeping it cold, but ensuring the air circulates properly so there are no “hot spots” in the corners of the trailer. If you are curious about the different vehicles used, we have a detailed breakdown of refrigerated truck types that you might find helpful.

5. Real-Time Monitoring

This is the “brain” of the operation. Throughout the entire journey, sensors are constantly recording the temperature. In the past, someone would have to check a thermometer manually. Today, we use IoT (Internet of Things) devices that send real-time alerts to a manager’s phone the second a temperature moves out of range. This allows for “intervention logistics” where a driver can be told to check their cooling unit before the product is ruined. For a deeper look at this technology, check out our resource on cold chain temperature monitoring.

The Different Temperature Bands

One common misconception is that “cold” means “frozen.” In reality, the cold chain is divided into several distinct temperature bands, each with its own set of rules and equipment. Here is a quick cheat sheet:

- Controlled Ambient (15°C to 25°C): This is for products that do not need to be cold but cannot get “hot.” Many over-the-counter medicines fall into this category.

- Chilled (2°C to 8°C): This is the “sweet spot” for most vaccines, fresh fruits, and dairy. It is cold enough to stop spoilage but warm enough to prevent freezing.

- Frozen (-18°C or colder): This is standard for frozen foods and meat. At this temperature, biological activity is essentially halted.

- Deep-Frozen / Cryogenic (-40°C to -150°C): This is the high-tech end of the scale. It is used for advanced biopharmaceuticals, cell and gene therapies, and certain specialized lab samples. It often requires liquid nitrogen instead of standard mechanical cooling.

What does this mean for you? It means that a single warehouse might need to manage four or five different climates at once. This adds a massive layer of complexity to the inventory management process.

The Critical Importance of the Cold Chain

Now, you might be wondering, “Why do we spend so much money and effort on this?” The short answer is safety, but there is more to it. The cold chain is one of the most significant drivers of global health and economic stability.

Public Health and Medicine

Without a reliable cold chain, we simply could not have a global healthcare system. Vaccines are the most obvious example. The World Health Organization (WHO) notes that maintaining the “cold chain” is essential for immunization programs to be effective. If the chain breaks, people get sick, and diseases that should be preventable start to spread. It is that simple.

Reducing Global Food Waste

We produce enough food to feed everyone on Earth, yet millions go hungry. Why? Because a huge portion of that food spoils before it ever reaches a consumer. A robust cold chain allows farmers in developing nations to get their products to market without them rotting in the heat. This increases their income and reduces the overall environmental impact of agriculture. When food is wasted, all the water, land, and energy used to grow it is also wasted.

Economic Growth and Trade

The cold chain allows for a truly global marketplace. It means a farmer in Chile can sell blueberries to a family in New York in the middle of January. This creates jobs, stabilizes food prices, and allows countries to specialize in the crops they grow best. It turns local agriculture into a global industry.

The Regulatory Landscape: Why Compliance Matters

Because the cold chain involves things we eat and medicines we take, it is heavily regulated. You cannot just throw some milk in a van and call it a day. In the United States, the Food and Drug Administration (FDA) has strict rules under the Food Safety Modernization Act (FSMA). These rules require companies to prove that they have maintained the correct temperatures throughout the entire journey.

In the pharmaceutical world, we talk about “Good Distribution Practices” (GDP). This is a set of standards that ensures the integrity of medicines. It requires validated storage, temperature mapping of warehouses, and documented contingency plans. If a company cannot prove their cold chain was intact, they may be forced to destroy the entire shipment, even if the product looks fine. This is why record-keeping is just as important as the cooling itself.

Major Challenges in Cold Chain Logistics

Let us be honest here. Running a cold chain is incredibly difficult. It is much more expensive and risky than standard logistics. Here are the hurdles that keep logistics managers up at night.

High Operating Costs

Refrigeration is an energy hog. Cold storage warehouses require a constant supply of electricity to keep the compressors running. Refrigerated trucks burn more fuel because they have to power the cooling unit as well as the engine. Then there is the cost of specialized labor. You need people who are trained to handle hazardous materials, operate complex cooling systems, and follow strict hygiene protocols.

The Risk of Equipment Failure

In a standard warehouse, if the power goes out, you might be in the dark, but your products are fine. In a cold warehouse, a power outage is a ticking time bomb. This is why these facilities require massive backup generators and redundant cooling systems. On the road, a broken belt in a truck’s refrigeration unit can ruin $100,000 worth of cargo in a matter of hours. This constant risk requires a level of maintenance and oversight that most industries never have to deal with.

The Complexity of Global Trade

Moving a temperature-sensitive product across international borders is a nightmare. What happens if a shipment of life-saving medicine is held up in customs for three days in a tropical climate? Or if a port in a developing nation doesn’t have enough “reefer plugs” to keep containers powered? Managing these global handoffs requires incredible coordination and a lot of backup planning.

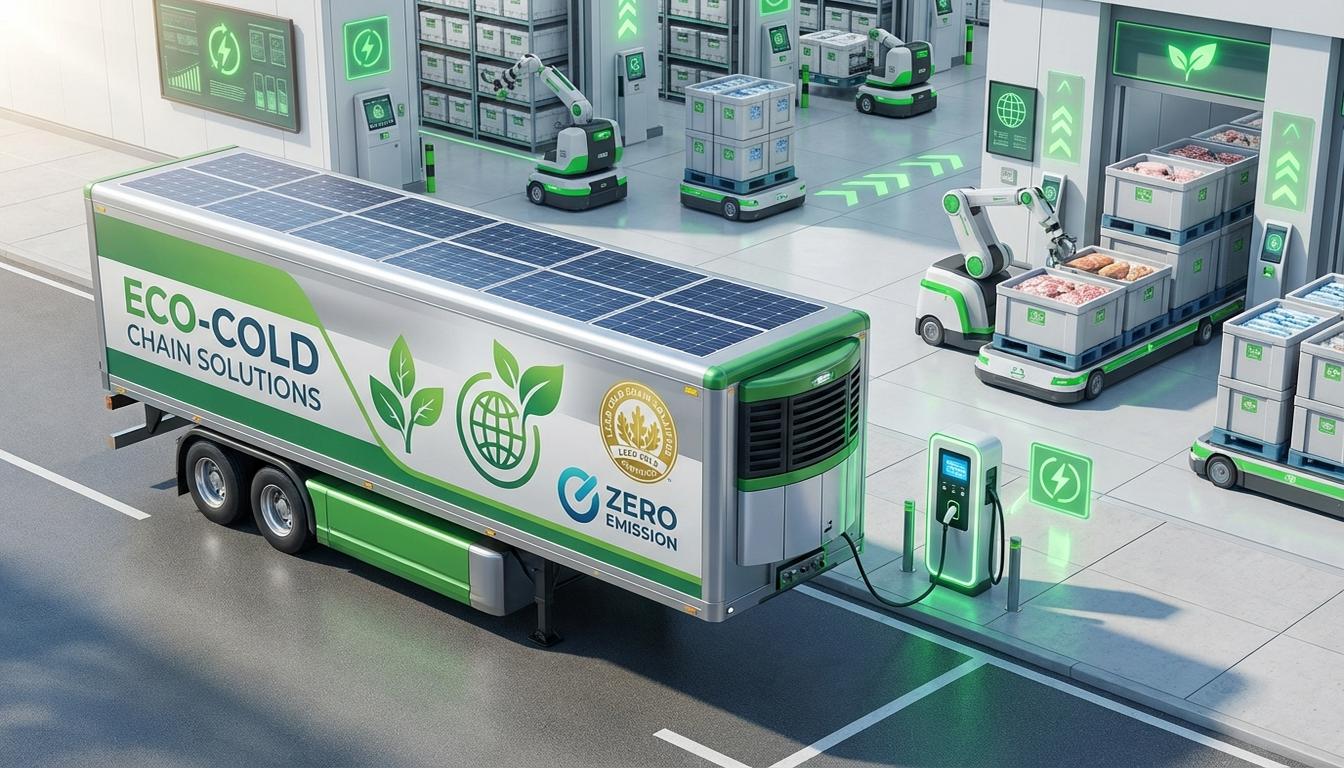

Future Trends: Where is the Industry Heading?

Despite the challenges, the cold chain industry is evolving rapidly. We are seeing a move toward more sustainable and “smarter” logistics. Here is what we found to be the most exciting trends.

1. Sustainability and Green Cooling: Companies are under pressure to reduce their carbon footprint. This is leading to the development of better insulation, solar-powered refrigerated trailers, and the use of natural refrigerants that don’t contribute to global warming. It is a win-win: better for the planet and cheaper for the company in the long run.

2. Automation and AI: We are seeing the rise of “smart warehouses” where robots handle the picking and packing in freezing temperatures. This reduces the time doors are left open and keeps human workers out of harsh environments. AI is also being used to predict when a cooling unit might fail before it actually happens.

3. The Rise of Personalized Medicine: As we move toward cell and gene therapies, the need for “ultra-cold” and “cryogenic” logistics is skyrocketing. These products are often “patient-specific,” meaning if the cold chain fails, you aren’t just losing money; you are losing a treatment designed for a specific person. This is pushing the boundaries of what is possible in thermal logistics.

Best Practices for a Strong Cold Chain

If you are responsible for a temperature-sensitive supply chain, you know there is no room for error. Here is the practical takeaway on how to keep things running smoothly.

- Invest in the Best Monitoring: Do not settle for basic data loggers. Use real-time IoT sensors that give you visibility into location and temperature at all times.

- Vet Your Partners: If you are using a 3PL (Third-Party Logistics provider), make sure they have a proven track record in the cold chain. Ask for their audit reports and see their contingency plans.

- Focus on Training: The best technology in the world won’t save you if a warehouse worker leaves a freezer door open. Continuous training on hygiene and handling is essential.

- Plan for the Worst: Always assume something will go wrong. Have backup power, backup transport routes, and clear protocols for what to do if a temperature excursion occurs.

Frequently Asked Questions

What happens if the cold chain is broken?

This comes up a lot, and the answer is usually not good. If a product moves out of its required temperature range, it is called a “temperature excursion.” Depending on the product, it might be immediately discarded. For food, this is to prevent bacterial growth. For pharmaceuticals, it is because the chemical structure may have changed, making the medicine ineffective or toxic.

Is cold chain logistics only for frozen food?

Great question. Actually, no. While frozen food is a big part of it, a huge portion of the cold chain is dedicated to “chilled” products like fresh produce, vaccines, and even certain electronics or chemicals. The cold chain covers everything from just below room temperature all the way down to cryogenic levels.

How do you monitor temperature on a moving truck?

Most modern refrigerated trucks use telematics. Sensors inside the trailer send data wirelessly to the driver’s dashboard and a central office. If the temperature fluctuates, the system triggers an alarm. Some high-end systems can even allow the central office to adjust the thermostat remotely.

What is “passive” vs “active” cold chain packaging?

This is where most people get confused. Active packaging has its own power source and mechanical cooling system, like a portable refrigerator. Passive packaging uses insulated materials and “coolants” like gel packs or dry ice to keep things cold without using electricity. Passive is common for smaller, shorter shipments.

Why is the cold chain so expensive?

The short answer is energy and equipment. You are paying for specialized vehicles, high-tech sensors, thick insulation, and a massive amount of electricity. Additionally, the risk is higher, which means insurance and specialized labor also cost more than standard logistics.

The Bottom Line

Cold chain logistics is one of those things that we don’t realize we need until it’s gone. It is a massive, complex, and incredibly important part of our global infrastructure. From the 18th-century ice trade to the modern era of AI-driven cryogenic shipping, we have come a long way. But the core challenge remains the same: fighting against the natural tendency of things to warm up and spoil.

What we hope you take away from this is a new appreciation for the effort that goes into that carton of milk or that bottle of medicine. It is the result of thousands of people, specialized machines, and constant monitoring all working in perfect harmony. If you are involved in this industry, you are part of a vital mission to keep the world fed and healthy.

Now that you have a solid grasp of how the cold chain works, where do you want to go next? Maybe you want to look deeper into the technology used in monitoring, or perhaps you are ready to look at how to design your own cold storage facility. Whatever the next step is, you are now equipped with the knowledge to navigate this “cool” world with confidence. You’ve got this!