Refrigerated Truck Types: Choosing the Right Equipment

Are you looking for the exact breakdown of refrigerated truck types for your specific cargo? You have come to the right place. While general guides cover the basics of transport, you need the specific details that actually help you select the right equipment for a delicate shipment. We are going to get straight into what works, what does not, and exactly what you should do to protect your inventory. Let us get specific.

Most of us in the industry simply say reefer when we mean any vehicle with a cooling unit. However, if you are managing a complex supply chain, you know that a 53 foot trailer used for frozen beef is a completely different machine than a small van delivering vaccines to a local clinic. Choosing the wrong configuration leads to more than just high fuel costs. It leads to rejected loads and broken compliance records. For a complete overview of the broader industry, check out our cold chain logistics guide. Now, let us look at the equipment itself.

The Fundamental Distinction: Refrigerated vs. Insulated Trucks

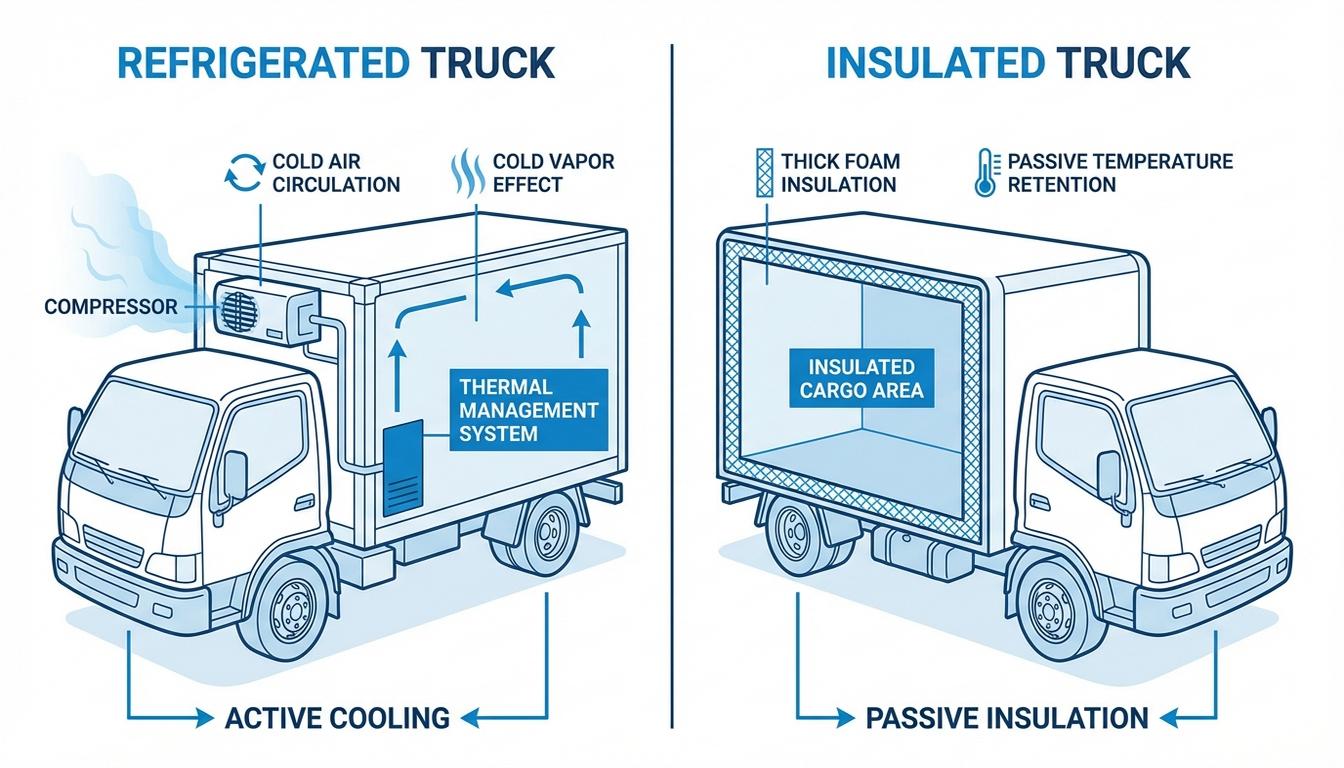

Here is the specific answer to a question we hear constantly. Is an insulated truck the same as a refrigerated truck? The short version is no, and here is why. The key difference lies in the presence of an active cooling system. This distinction changes everything when it comes to route planning and product safety.

Refrigerated trucks, or reefers, are equipped with an active refrigeration unit. This mechanical system typically consists of a compressor, a condenser, and an evaporator. It is designed to maintain a specific set point by removing heat from the cargo space. These vehicles are the workhorses of long haul transport because they can fight off ambient heat for days at a time.

Insulated trucks are passive. They rely on thick walls, usually made of polyurethane foam or high density sandwich panels, to slow down the transfer of heat. They do not have a motor to create cold air. These are used primarily for short local deliveries where the product is already at the target temperature and only needs to stay that way for an hour or two. If you try to use an insulated truck for a cross country haul, your cargo will likely reach ambient temperatures before the first state line. For your specific case, always check if the cargo requires active temperature maintenance or just thermal protection.

The practical takeaway is simple. If your cargo is sensitive to even a five degree fluctuation over several hours, you need a reefer. If you are moving pre chilled produce ten miles down the road, a well insulated van might save you a significant amount on equipment costs.

Classifying Refrigerated Truck Types by Body Configuration

When it comes to refrigerated truck types, size and shape dictate the mission. We categorize these vehicles based on their chassis and their capacity. Let us get into the details of the four most common configurations you will encounter in the field.

Refrigerated Vans

These are small, nimble vehicles often used for last mile delivery. You will see them delivering meal kits, floral arrangements, or pharmaceutical supplies in crowded urban centers. They typically use a compressor driven by the vehicle engine itself. This means they are efficient for stop and go traffic but might struggle to maintain ultra low temperatures if the engine is frequently turned off. In practice, this means you should verify the cooling capacity if you are running a multi drop route in a hot climate.

Rigid Refrigerated Trucks

Also known as straight trucks, these have a fixed cargo box attached to the frame. They are the standard for regional distribution. Because they are larger than vans but more maneuverable than semi trailers, they are perfect for delivering to grocery stores or restaurants. Most of these units use a self contained diesel engine to power the cooling unit, which provides much more consistent performance than a van. According to industry standards from the U.S. Department of Transportation, these vehicles often bridge the gap between long haul hubs and local retail outlets.

Refrigerated Semi-Trailers (Reefer Trailers)

This is the dominant form of cold transport in North America. These trailers are usually 48 to 53 feet long. The refrigeration unit is almost always nose mounted, meaning it sits on the front of the trailer outside the cargo space. These machines are engineered for the long haul. They feature heavy duty insulation and advanced airflow systems. Modern reefers even use telematics to allow managers to change the temperature settings remotely. Your best move here is to ensure the trailer has a corrugated floor to allow air to circulate under the pallets.

Multi-Temperature Trucks

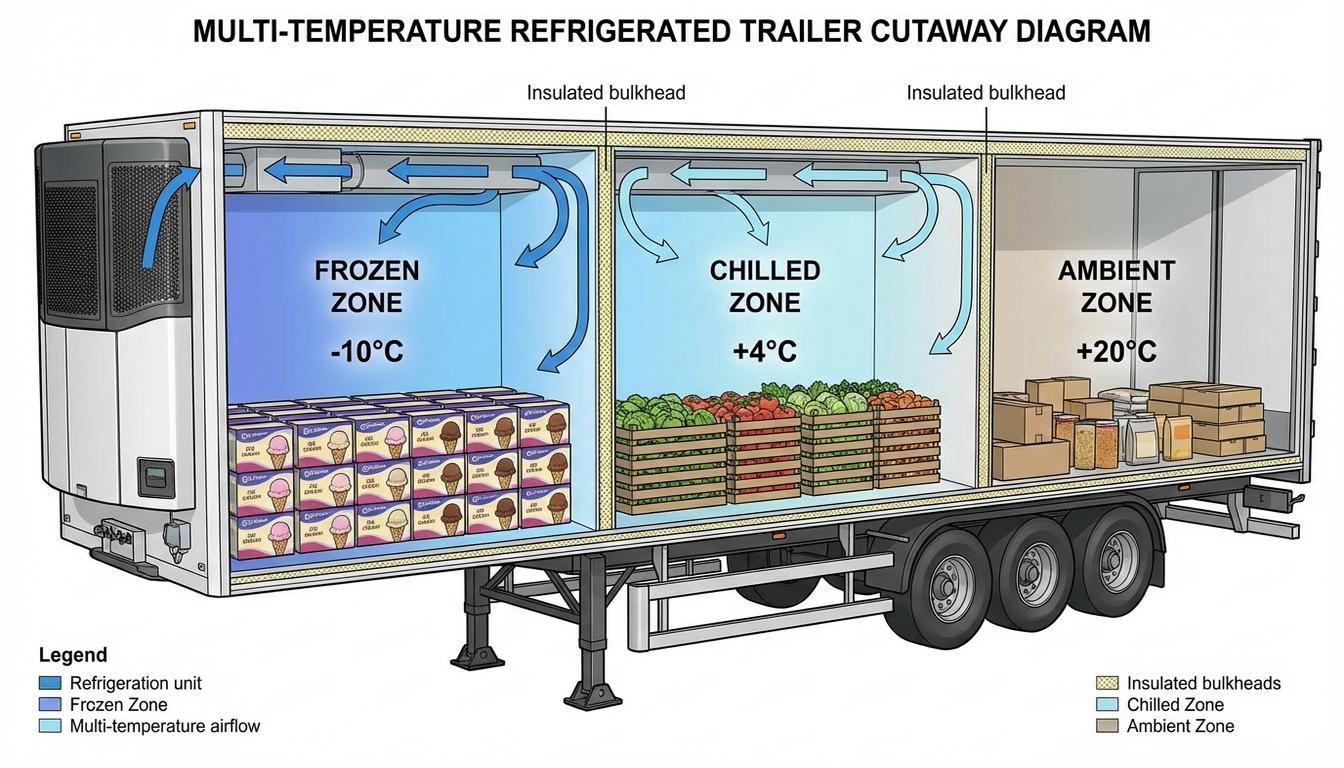

This is where it gets practical for complex deliveries. Multi temperature vehicles use internal bulkheads to divide the cargo area into different zones. One section might be set to -10 degrees for ice cream, while another is set to 35 degrees for fresh milk. Each zone has its own evaporator, allowing a single truck to handle a diverse load. This is the detail that changes everything for distributors who want to maximize their fleet efficiency without compromising food safety.

Temperature Regimes: Chilled vs. Frozen vs. Heated

We need to talk about what happens inside the box. Not all cold transport is the same. The industry divides refrigerated truck types into specific temperature regimes based on the biological or chemical needs of the cargo. Monitoring these temperatures in real-time is crucial, which is why we recommend checking out cold chain temperature monitoring techniques.

- Chilled Transport (+2 °C to +8 °C): This range is for fresh produce, dairy, and some pharmaceuticals. The goal here is to prevent spoilage without freezing the product. Freezing a head of lettuce is just as damaging as letting it get too warm.

- Frozen Transport (-18 °C to -25 °C): This is the standard for meats, seafood, and frozen meals. The refrigeration units in these trucks must be significantly more powerful to maintain these levels against high outside temperatures.

- Deep-Frozen or Cryogenic (Below -150 °C): This is a highly specialized niche. Cryogenic reefers use liquid nitrogen or CO2 rather than a mechanical compressor. These are used almost exclusively for vaccines, biological samples, or high tech industrial materials.

- Heated Transport (Above Freezing): It might sound counterintuitive, but many temperature controlled vehicles are used to keep things warm. In northern climates during winter, products like paint, chemicals, and certain beverages must be protected from freezing. These units use a heat pump or a diesel heater to maintain a stable environment.

The real question is how your specific product reacts to temperature excursions. If you are moving high value biologics, you cannot settle for a standard chilled truck. You need specialized equipment with redundant cooling systems. Your next step is to match your product’s stability data to the specific capabilities of the truck type you hire.

Cooling Technologies: Mechanical vs. Cryogenic

Let us look at this closely. How the truck actually creates the cold environment matters for your bottom line and your reliability. Most people assume every reefer uses a standard motor, but technology is shifting rapidly. The design of your truck often mirrors the layout of your facility, so you might find it useful to look into cold storage warehouse design to see how they integrate.

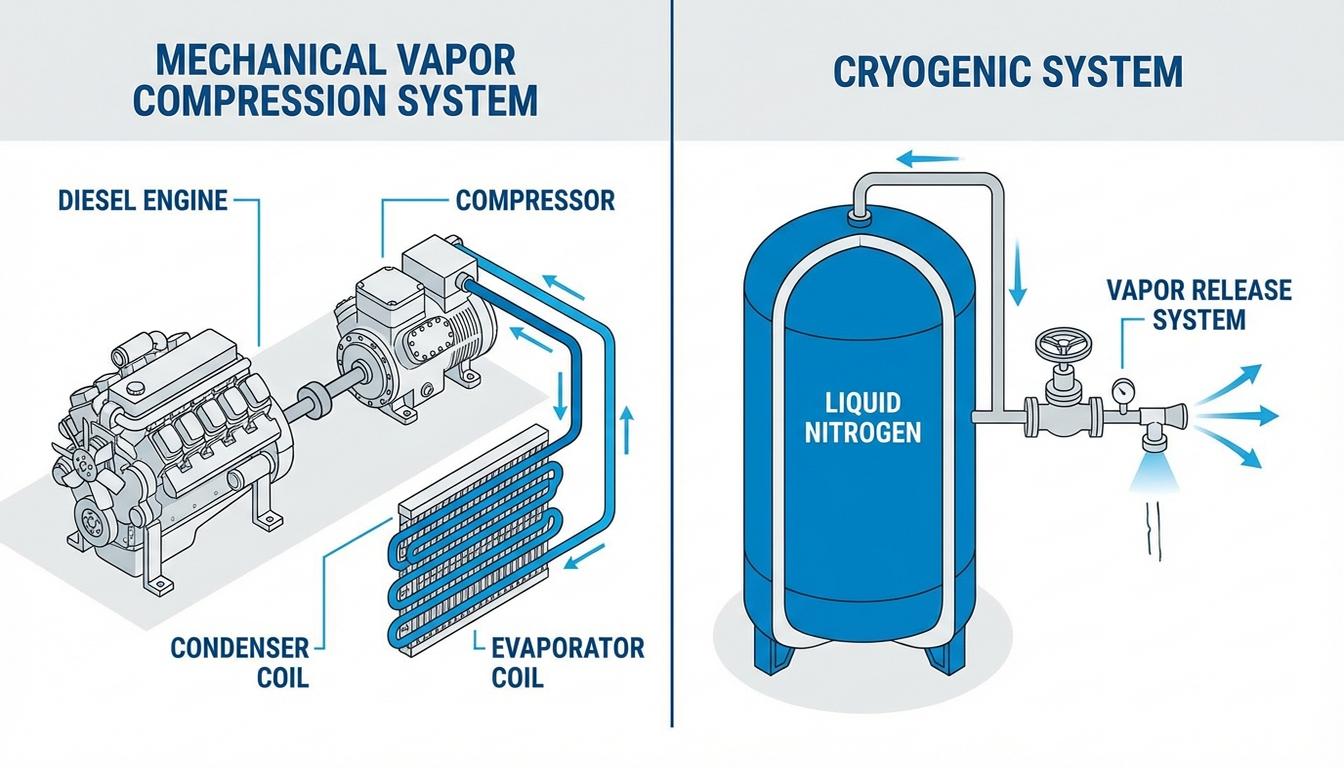

Mechanical Refrigeration

This is the vapor compression cycle you are familiar with in your home refrigerator, just much larger and louder. A diesel engine drives a compressor that circulates refrigerant. It is reliable, well understood, and easy to service. The downside is the fuel consumption and the emissions. However, for 95 percent of food transport, this remains the gold standard. Here is the thing most people miss. Many modern mechanical units now feature electric standby. This allows the driver to plug into a power outlet at a warehouse, saving fuel and reducing noise while parked.

Cryogenic Cooling Systems

Instead of a motor, these systems use the evaporation of liquid nitrogen or carbon dioxide to absorb heat. This is an incredibly fast way to cool a trailer. It is also nearly silent because there are no moving parts. This makes it ideal for nighttime deliveries in residential areas. However, it requires a specialized infrastructure to refill the tanks. Research from the Environmental Protection Agency suggests that while cryogenic systems reduce tailpipe emissions, the cost per mile can be higher depending on the price of nitrogen.

Hybrid and Electric Units

The industry is moving toward fully electric reefers. These units run on large battery packs or are powered by the truck’s electric drivetrain. They are extremely quiet and perfect for urban zones with strict emissions laws. In practice, this means you should consider these for your last mile fleet if you are operating in cities with “green zones.”

Quick Reference: Refrigerated Truck Types at a Glance

- Refrigerated Van: Best for last mile, urban delivery, and small batches.

- Rigid Truck: Best for regional distribution and multi stop routes.

- Reefer Trailer (53 ft): Best for long haul, high volume, and bulk commodities.

- Multi-Temp Trailer: Best for mixed loads (frozen and chilled) in one trip.

- Cryogenic Reefer: Best for ultra low temperatures and silent urban delivery.

- Heated Truck: Best for protecting freeze sensitive chemicals in winter.

Operational Secrets for Getting the Most from Your Equipment

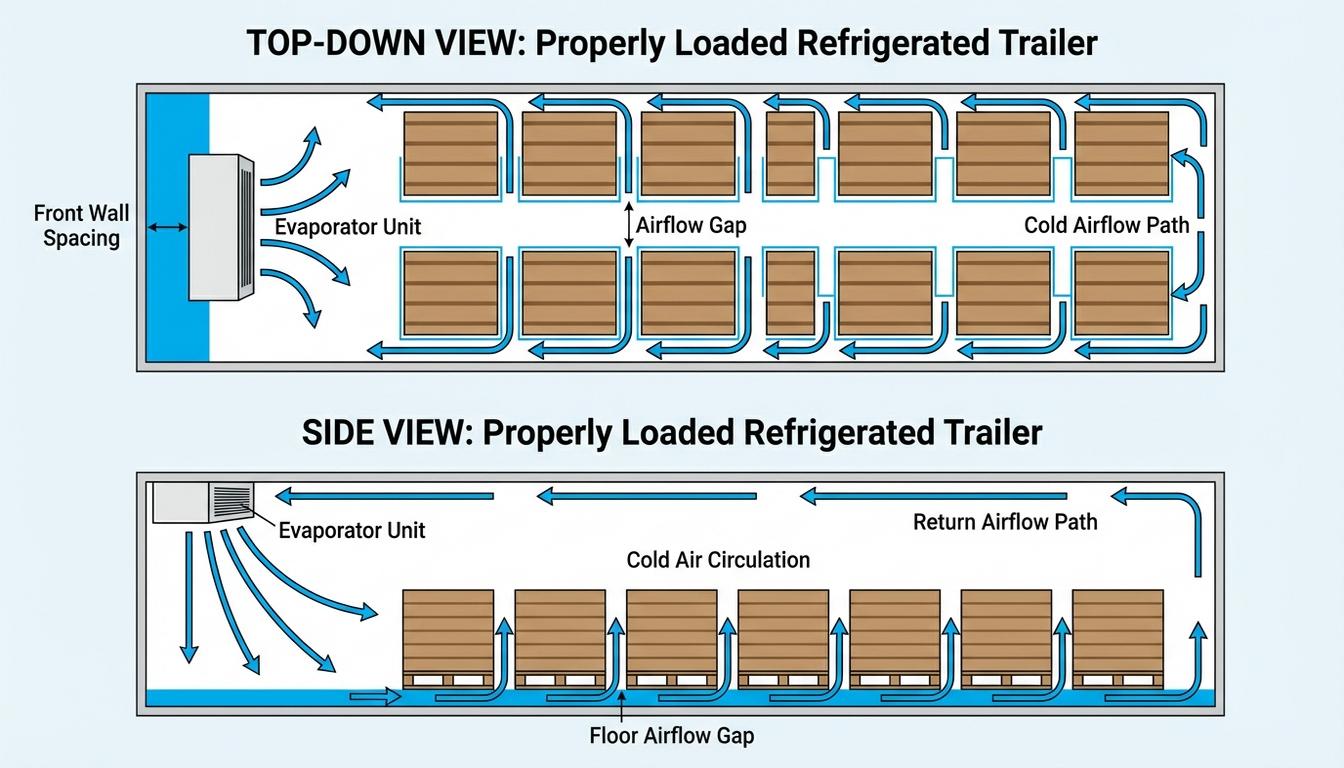

Choosing the right truck is only half the battle. If you do not operate it correctly, the type of truck will not matter. We have seen this constantly. A shipper hires a top of the line 53 foot reefer but fails to manage the airflow, leading to a rejected load at the destination. Let us get specific about how to prevent that.

Pre-cooling is non-negotiable. A reefer unit is designed to maintain the temperature of the cargo, not to lower it. If you load warm pallets into a cold trailer, the unit will struggle to pull the core temperature down. This often results in the outer layers of the product freezing while the core stays too warm. Always pre cool both the trailer and the product to the target temperature before loading.

Airflow is the lifeblood of the reefer. You must leave space at the front and back of the trailer. Never block the evaporator fans at the front. If air cannot circulate, you will develop hot spots in the middle of the load. This is where most spoilage occurs. Use pallets to keep the cargo off the floor and ensure there is a clear path for air to return to the cooling unit. For your specific case, use a loading diagram to ensure your team leaves the necessary gaps.

Manage your door openings. Every time the doors open, cold air falls out and warm, moist air rushes in. This moisture turns into frost on the evaporator coils, forcing the unit into a defrost cycle. During a defrost cycle, the unit is not cooling. If you are in a high humidity environment, use strip curtains to keep the cold air inside during unloading. The action item here is simple. Train your drivers to minimize the time the doors are open and to use bulkheads if the truck is only partially full.

Common Questions About Refrigerated Truck Types

What is a reefer truck exactly?

The answer is a vehicle equipped with an insulated body and an active mechanical refrigeration unit. It is designed to transport perishable goods at specific temperatures, ranging from deep frozen to heated, depending on the cargo requirements.

How long do refrigerated trailers usually last?

The direct answer is that a well maintained trailer can last 10 to 15 years, but the refrigeration unit itself often needs a major overhaul or replacement after 7 to 10 years. Maintenance of the insulation is key, as foam can degrade and absorb moisture over time, reducing efficiency.

Can one truck carry both frozen and fresh food?

Yes, and here is how. You must use a multi temperature truck equipped with internal bulkheads. These insulated walls separate the trailer into zones, each with its own temperature control, allowing you to carry frozen meat and fresh produce simultaneously.

What is the standard size for a long haul reefer?

In North America, the 53 foot semi trailer is the standard. It provides the maximum volume for high density freight while fitting within the legal length limits for most interstate highways. These trailers are almost always 102 inches wide to accommodate standard pallets.

How much fuel does a reefer unit use?

It depends on the ambient temperature and the set point, but a standard diesel reefer unit typically consumes between 0.4 and 1.1 gallons of fuel per hour. Using start stop mode can significantly reduce this consumption when transporting less sensitive goods.

Moving Forward with the Right Fleet

Understanding the nuances of refrigerated truck types is what separates a successful logistics manager from one who is constantly dealing with claims. We have looked at the core differences between active and passive cooling, the various body styles available, and the technology that makes it all possible. The details matter because your cargo depends on them. There is a reason this specific aspect of logistics is so highly regulated. The safety of our food and medicine supply relies on the integrity of these vehicles.

Your best move right now is to audit your current shipping lanes. Are you using a full 53 foot trailer for loads that could fit in a rigid truck? Are you paying for active refrigeration on products that only need an insulated van? By matching the specific truck type to the specific needs of your cargo, you can reduce costs while increasing reliability. Remember to keep the airflow moving, pre cool your loads, and always trust the data over your gut feeling when it comes to temperature set points.