Last Mile Delivery Challenges and How to Overcome Them

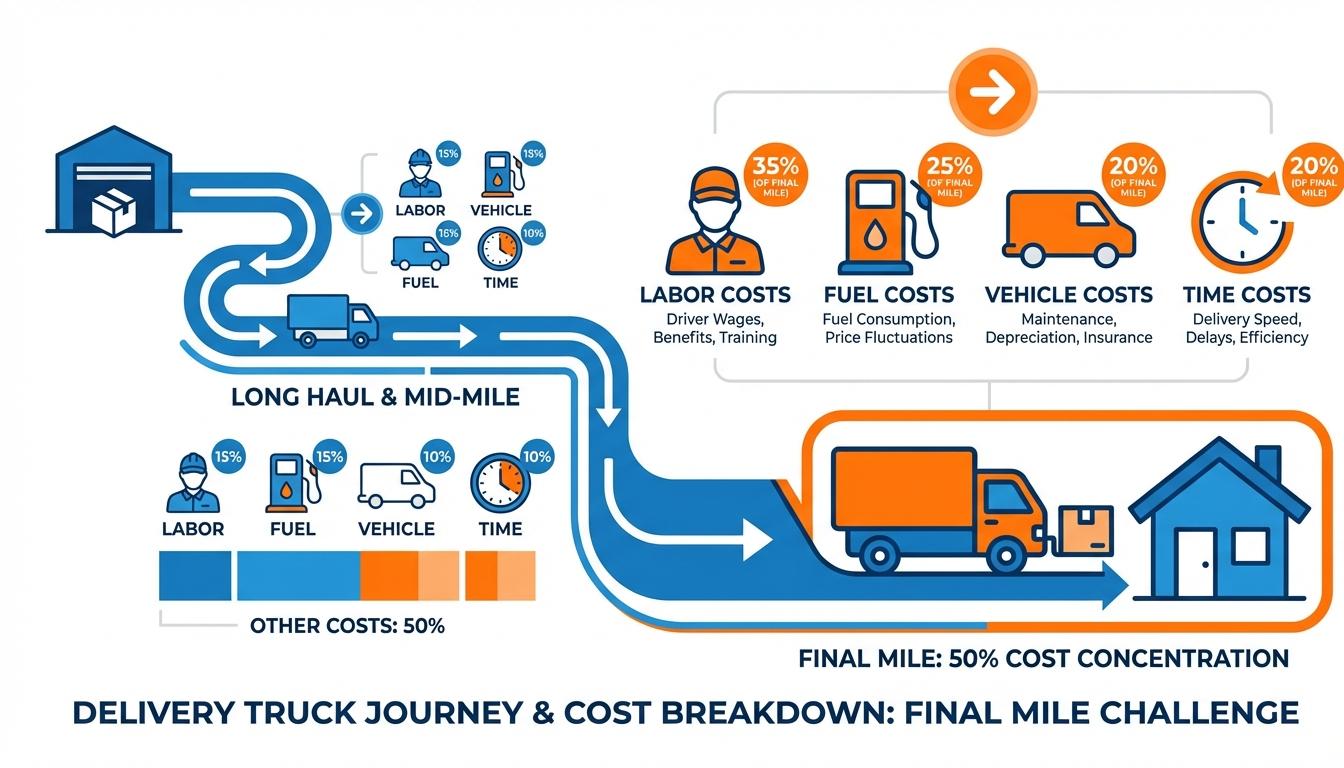

Imagine tracking a package all the way to a local facility just a few miles from your home, only to watch it linger there like a guest who won’t leave, making you wait two more days for it to finally arrive It is a frustrating experience for a customer, but for the business behind that package, it is often a logistical nightmare. These last mile delivery challenges represent the single most expensive and complicated part of the entire shipping journey. In fact, this final stretch can account for around 50 percent of the total cost of shipping a product. When you think about the thousands of miles a package might travel across oceans or continents, it is wild to realize that the last few miles are what really break the bank.

We understand how overwhelming this can feel if you are trying to manage a supply chain or run an e-commerce business. The pressure to deliver faster, cheaper, and with more transparency has never been higher. You are likely looking for ways to streamline your operations without sacrificing your profit margins or your sanity. This guide is here to help you navigate those waters. We have looked at the data, the trends, and the real-world bottlenecks to give you a clear picture of what is happening in final mile logistics today. Let us break down exactly why this stage is so difficult and, more importantly, what you can do about it.

In this post, we are going to explore everything from the historical roots of the “last mile” to the modern tech solutions that are changing the game. We will talk about urban congestion, the rising cost of labor, and the specific ways you can optimize your routes to save time and money. Whether you are just starting to scale your delivery operations or you are a seasoned pro looking for an edge, there is something here for you. We are in this together, so let us get started with the basics.

What Exactly is Last Mile Delivery?

To solve a problem, we first have to define it. In the world of logistics, the last mile refers to the very last step of the delivery process. This is the moment a package leaves a local distribution center or a retail store and makes its way to the customer’s front door. It sounds simple enough, but the reality is anything but. The term actually comes from the telecommunications industry, where it described the difficulty of connecting individual homes to the main phone and internet networks. Logistics professionals adopted the term because the challenge is identical. It is easy to move a thousand boxes at once on a massive ship, but it is incredibly hard to move those thousand boxes to a thousand different houses.

Historically, this stage was seen as just a minor part of the overhead. Then came the e-commerce explosion. Platforms like Amazon changed the way we shop, and suddenly, the “final mile” became the most important part of the brand experience. If the delivery is late or the box is crushed, the customer does not blame the manufacturer in China or the shipping line in the Pacific. They blame the company that took their order. This has turned final mile logistics into a strategic battlefield where speed and reliability are the primary weapons.

What makes this stage so unique is its lack of scale. In the middle of the supply chain, you have massive warehouses and giant trucks moving huge volumes. Efficiency is built into the system. But in the last mile, that efficiency vanishes. You are dealing with individual addresses, narrow city streets, gated communities, and customers who might not even be home. Every stop is a unique puzzle, and every minute spent idling in traffic or looking for a parking spot adds to the cost.

The Rise of Customer Expectations

The “Amazon Effect” is a phrase you will hear a lot in this industry, and for good reason. It has completely reset the bar for what customers expect. It used to be that five-to-seven-day shipping was perfectly acceptable. Now, if a package takes more than two days, people start checking their tracking numbers with a sense of dread. According to research from DHL, the demand for same-day and next-day delivery is growing faster than almost any other segment of the market.

This creates a massive amount of pressure on businesses. You have to be fast, but you also have to be cheap. Most customers today expect free shipping as a standard feature, not a luxury. This means the business has to eat that roughly 50 percent shipping cost we mentioned earlier. It is a tightrope walk. If you charge for shipping, you lose the sale. If you do not charge, you lose your profit. Finding the middle ground requires a deep understanding of the delivery logistics issues that drive these costs up.

The Real Cost of the Last Mile

We have mentioned that roughly 50 percent figure a few times now, but let us actually look at why that number is so high. It is not just one thing. It is a combination of labor, fuel, equipment, and inefficiency that creates a perfect storm of expenses. When a driver is out on a route, they are not just driving. They are navigating, parking, walking to doors, taking photos for proof of delivery, and sometimes even dealing with returns. All of that takes time, and in logistics, time is literally money.

Labor is usually the biggest piece of the pie. As the demand for drivers has skyrocketed, so have the wages required to keep them. Turnover is also high in this industry because the work is demanding. Every time a company has to hire and train a new driver, their last mile delivery challenges grow. Then you have fuel costs, which are notoriously volatile. A van idling in city traffic for three hours a day is burning through your margins one gallon at a time.

Here is something most people miss. The cost of a delivery does not end when the package is dropped off. If the customer is not home and the package requires a signature, that is a “failed delivery.” Now the driver has to come back tomorrow, effectively doubling the cost of that single shipment. Or, even worse, the customer decides to return the item. Now you have to deal with reverse logistics, which is often even more expensive than the initial delivery. For more on how to tackle this specific issue, we have a detailed look at failed delivery reduction strategies that can save you a lot of headaches.

The Density Dilemma

The key to making money in the last mile is density. If a driver can make 20 deliveries on a single block, the cost per package is tiny. This is why urban centers are, in some ways, easier than rural ones. In a rural setting, a driver might have to drive five miles between stops. That is ten minutes of labor and a quarter-gallon of gas for a single box. It is almost impossible to make that profitable without high delivery fees.

However, density brings its own set of problems. In a city, you might have 50 packages for one apartment building, but where does the driver park? If they spend 15 minutes looking for a spot or get a $60 parking ticket, the “efficient” dense route suddenly becomes a financial loser. This is the last mile problem in a nutshell. Whether you are in the middle of nowhere or the middle of Manhattan, the environment is constantly working against your bottom line.

Urban Delivery Challenges: The City Bottleneck

If you operate in a major metro area, you already know that urban delivery challenges are in a league of their own. Traffic is the most obvious villain. It is unpredictable, it is frustrating, and it is expensive. A route that takes two hours at 10:00 AM might take four hours at 4:00 PM. If your software does not account for these shifts in real-time, your drivers will never meet their windows.

Then there are the regulations. Many cities are starting to implement “green zones” or low-emission zones where only electric vehicles are allowed. Others are restricting the times of day that large trucks can make deliveries. While these rules are great for the environment and city livability, they add a layer of complexity to your planning. You cannot just send any van to any address anymore. You have to match the right vehicle to the right zone at the right time.

Let us be real for a moment. Parking is the silent killer of urban logistics. In many cities, delivery companies simply treat parking tickets as a cost of doing business. They pay millions of dollars in fines every year because there simply isn’t enough curb space for the number of packages being delivered. This is where last mile bottlenecks really start to choke a business. When a driver has to double-park, they are not only risking a fine, they are also blocking traffic and creating safety hazards, all of which slow down the entire network.

The Rise of Micro-Fulfillment

To fight back against these urban issues, many companies are moving their inventory closer to the customer. This is called micro-fulfillment. Instead of one massive warehouse 50 miles outside of town, they use several tiny warehouses right in the heart of the city. Sometimes these are even “dark stores” or backrooms of existing retail locations. By shortening the physical distance between the product and the customer, you can bypass a lot of the highway traffic and get packages into the hands of bike couriers or walkers who don’t have to worry about parking.

This strategy is particularly popular for grocery and food delivery. When you have a 30-minute delivery window, you don’t have time to cross a bridge or go through a tunnel. You need to be right around the corner. While this increases your real estate costs, the savings in fuel and time can be significant. It is all about finding the right balance for your specific product and customer base.

The Role of Technology in Solving Inefficiencies

So, how do we fix all of this? The short answer is technology, but there is more to it than just buying a new app. You need a suite of tools that talk to each other and provide a single source of truth for your operations. Without tech, you are essentially guessing. You are guessing which route is fastest, you are guessing when the driver will arrive, and you are guessing why a delivery failed. Last mile inefficiencies thrive on guesswork.

The most important tool in your arsenal is routing software. This is not just Google Maps. It is a complex algorithm that takes into account hundreds of variables, including traffic patterns, vehicle capacity, driver breaks, and delivery windows. A good system can reduce your mileage by around 10–20 percent or more. If you want to see how this works in practice, you should definitely check out our guide on delivery route optimization to see the logic behind the math.

Beyond routing, you need real-time tracking. This is not just for your benefit. Customers today want to see exactly where their package is. They want the “Uber-style” experience of watching a little icon move on a map. When you provide this transparency, you reduce the number of customer service calls and increase the likelihood that the person will be home when the driver arrives. It builds trust, and in a crowded market, trust is a competitive advantage.

Data-Driven Decision Making

Here is what actually matters when it comes to tech. It is not about the bells and whistles. It is about the data you collect. Every delivery is a data point. If you notice that deliveries to a certain neighborhood always take 10 minutes longer than expected, you can adjust your planning. If you see that one driver is consistently more efficient than others, you can figure out what they are doing differently and train the rest of your team. This constant loop of feedback and adjustment is how you turn a struggling operation into a well-oiled machine.

What we found is that the most successful companies are those that embrace “dynamic” planning. They don’t just set a route in the morning and hope for the best. They are constantly adjusting based on what is happening on the ground. If a driver gets stuck at a loading dock, the system should automatically reassign their next three stops to another driver who is ahead of schedule. That level of agility is only possible with modern software.

The Human Element: Managing Drivers and Labor

It is easy to get caught up in the software and the stats, but we have to remember that last mile delivery is still a human-powered business. Your drivers are the face of your company. They are the only people your customers actually interact with. If they are stressed, overworked, or poorly managed, your brand will suffer. Delivery logistics issues are often just as much about people as they are about packages.

One of the biggest last mile problems today is the driver shortage. There is more work than there are people to do it, which means drivers have options. If your routes are poorly planned and your drivers are constantly frustrated by bad directions or impossible schedules, they will leave. High turnover is a silent killer of profitability. It costs thousands of dollars to onboard a new driver, and they are never as efficient as a veteran who knows the shortcuts and the gate codes.

So, how do you keep your team happy? Communication is a great place to start. Give them tools that actually help them do their jobs. A driver app that handles navigation, manifest management, and proof of delivery in one place is a godsend. It reduces the cognitive load on the driver and lets them focus on the road. Also, let us be real. Fair pay and realistic expectations go a long way. If you are using data to set your routes, make sure that data is accurate so you aren’t asking your team to do the impossible.

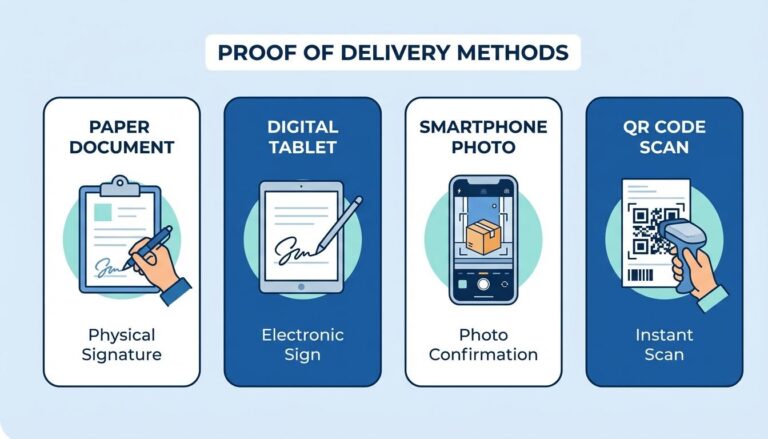

Proof of Delivery and Accountability

Another way to help your drivers is to give them a clear process for finishing a job. This is where proof of delivery methods come in. Whether it is a signature, a photo, or a GPS ping, having a standardized way to prove a package was delivered protects both the driver and the company. It eliminates the “he said, she said” arguments with customers and provides a clear record of work performed.

We have spent a lot of time looking at different ways to handle this. If you are curious about the pros and cons of different approaches, take a look at our deep dive into proof of delivery methods. It is a small detail that can prevent a lot of large-scale headaches. When a driver knows they have a solid, tech-backed way to verify their work, they feel more confident and less likely to be blamed for things out of their control.

Sustainability and the Future of the Last Mile

The conversation about last mile delivery challenges is shifting. It is no longer just about cost and speed. It is also about sustainability. As e-commerce grows, so does the number of delivery vans on the road, and that means more emissions and more congestion. Consumers are starting to care about the carbon footprint of their “free shipping,” and regulators are taking notice too.

According to the Association for Supply Chain Management, sustainability is becoming a key metric for logistics success. This is leading to a massive push toward Electric Vehicles (EVs). While the upfront cost of an electric fleet is higher, the long-term savings in maintenance and fuel are substantial. Plus, they are quieter and cleaner, making them much more “city-friendly.”

But sustainability isn’t just about the vehicles. It is also about efficiency. Every mile you cut from a route is a mile that doesn’t burn fuel. Every failed delivery you prevent is one less trip a van has to make. This is where the goals of profitability and sustainability actually align. When you optimize your last mile, you aren’t just saving money; you are also reducing your environmental impact. It is a win-win that most companies are starting to prioritize.

Drones, Robots, and Autonomous Tech

You might be wondering about the “sci-fi” side of things. Are we all going to get our packages from drones soon? The answer is: maybe, but not as soon as the headlines suggest. While companies like Amazon and FedEx are testing drones and sidewalk robots, there are still massive hurdles. FAA regulations, battery life, and the “porch pirate” problem are all real obstacles.

However, we are seeing real progress in autonomous delivery for specific use cases. Think of university campuses or planned communities where the environment is controlled. In these spots, small robots are already making deliveries. For the broader world, though, the human-driven van is going to be the king of the last mile for the foreseeable future. The tech will likely focus on “driver-assist” features first, helping the human be more efficient rather than replacing them entirely.

Actionable Strategies to Overcome Bottlenecks

If you are feeling a bit overwhelmed by all these challenges, do not worry. We promised practical advice, and here is where we deliver it. You don’t have to fix everything at once. The key is to pick the areas where you can have the biggest impact with the least amount of friction. Here is a breakdown of where we recommend you start.

- Implement Route Optimization Immediately: If you are still manually planning routes, you are leaving money on the table. Even a simple software solution can pay for itself in fuel savings and reduced labor hours within the first months.

- Focus on Delivery Density: Look for ways to cluster your orders. Maybe you offer a small discount for customers who choose a “green delivery day” when you already have a driver in their area.

- Enhance Customer Communication: Send automated texts when the driver is five stops away. This simple step can drastically reduce failed deliveries because people will actually make an effort to be home.

- Invest in Driver Training: Don’t just teach them how to drive. Teach them how to use your tech and how to handle common urban obstacles. A little bit of knowledge goes a long way in reducing stress.

- Use Data to Review Your Failures: Once a week, look at your “failed deliveries” and “late deliveries.” Look for patterns. Is it a specific neighborhood? A specific time of day? Fix the pattern, not just the individual package.

The good news is that even small improvements in the last mile can lead to huge savings. Because it is such a large portion of your total cost, a 5 percent increase in efficiency can result in a significant boost to your bottom line. You don’t have to be Amazon to be efficient. You just have to be intentional.

Remember, the goal is not perfection. The goal is progress. Every time you shave a minute off a stop or a mile off a route, you are winning. This is a game of inches, and the businesses that pay attention to those inches are the ones that will thrive in the long run.

Frequently Asked Questions

What is the biggest challenge in last mile delivery?

Great question. While there are many, the biggest is almost always cost. Because it is so labor-intensive and lacks the scale of other shipping stages, it often accounts for around half of the total shipping expense. Managing that cost while meeting customer demands for speed is the ultimate balancing act.

Why is urban delivery so much harder than rural delivery?

This comes up a lot, and the answer is congestion. In a city, you have plenty of customers close together (high density), but you have to deal with traffic, lack of parking, and strict regulations. In a rural area, you have the opposite: easy driving and parking, but long distances between stops. Both are difficult, but urban areas present more unpredictable “bottlenecks.”

How does route optimization software actually save money?

It is simpler than you might expect. By using algorithms to find the most efficient path, the software reduces the number of miles driven and the amount of time the engine is idling. This leads directly to lower fuel costs and lower labor costs. It also allows drivers to make more stops per hour, which increases your overall capacity.

Can small businesses compete with giants like Amazon in the last mile?

Yes, they can. While you might not have a fleet of thousands, you can be more agile. By using the same types of technology, like real-time tracking and optimization software, you can provide a high-quality experience. Many customers also prefer supporting local businesses if the delivery experience is reliable and transparent.

What is “failed delivery” and why does it matter?

A failed delivery happens when a driver arrives at a destination but cannot complete the drop-off, usually because a signature is required and no one is home. This matters because it basically doubles the cost of that delivery. The driver has to return to the hub and then try again the next day, using more fuel and more labor for the same single package.

How is the “Amazon Effect” changing the industry?

The short answer is that it has made speed and transparency mandatory. Customers now expect to see where their package is at all times and want it delivered as quickly as possible, often for free. This has forced all businesses to look for ways to optimize their last mile just to stay competitive.

A Path Forward for Your Logistics

We have covered a lot of ground here, from the roughly 50 percent cost reality to the high-tech future of robots and drones. If there is one thing we want you to take away, it is that the last mile is no longer a “set it and forget it” part of your business. It is a dynamic, challenging, and critically important stage that requires your attention. The last mile delivery challenges we discussed are real, but they are not insurmountable. By combining the right technology with a focus on driver happiness and customer transparency, you can turn your final mile from a cost center into a competitive advantage.

What we found is that the most successful companies are the ones that stop viewing delivery as just a “necessary evil” and start seeing it as the final touchpoint of their customer service. Every package delivered on time and with a smile is a chance to build loyalty. Every optimized route is a chance to reinvest in your growth. It might seem complicated at first, but if you take it step by step, you will be surprised at how much you can improve.

So, what is the next step for you? We suggest taking a hard look at your current delivery data. Where are the bottlenecks? Where are the hidden costs? Once you know where you stand, you can start making the changes that matter. You have got this, and we are here to help you every step of the way. Ready to start optimizing? Your customers are waiting.