Measuring Your Logistics Carbon Footprint Accurately

Looking for the exact breakdown of your logistics carbon footprint? You have come to the right place. While general guides cover the basics, you need the specific details that actually help you quantify the impact of every pallet and parcel. We are going to get straight into what works, what does not, and exactly what you should do to measure these numbers with precision. Let us get specific.

If you are reading this, you probably already know that transportation and warehousing are heavy hitters in the climate conversation. You are looking for the specific answer, not the general overview. This is the detailed breakdown you have been searching for. For a complete overview of broader supply chain sustainability, check out our main guide on the sustainable logistics guide. Now, let us look at how to actually calculate these numbers without getting lost in the weeds.

The True Scope of a Logistics Carbon Footprint

When we talk about a logistics carbon footprint, we are referring to the total greenhouse gas (GHG) emissions generated by moving, storing, and handling goods. This is not just about the tailpipe emissions from a truck. It includes the energy used to keep a warehouse at 60 degrees, the fuel burned by a cargo ship, and even the idling time at a congested port. In carbon accounting terms, this is a major part of your Scope 3 emissions if you are a shipper, or Scope 1 if you own the fleet.

The scale of this challenge is massive. The logistics sector is estimated to account for up to about 11% of global greenhouse gas emissions when you include freight, warehouses, and ports. Freight transport alone is responsible for nearly 10% of global CO2 emissions. In the United States, transportation is the largest emitting sector, accounting for 29% of total national GHG emissions in 2022. According to the Environmental Protection Agency, the bulk of these emissions come from burning fossil fuels in medium and heavy duty trucks, ships, and aircraft.

Here is the specific answer to why this matters for your reporting. If you cannot measure these emissions accurately, you cannot manage them. The global freight demand is expected to roughly double between 2019 and 2050. Without a precise measurement strategy, your carbon reporting will quickly fall behind regulatory requirements and customer expectations.

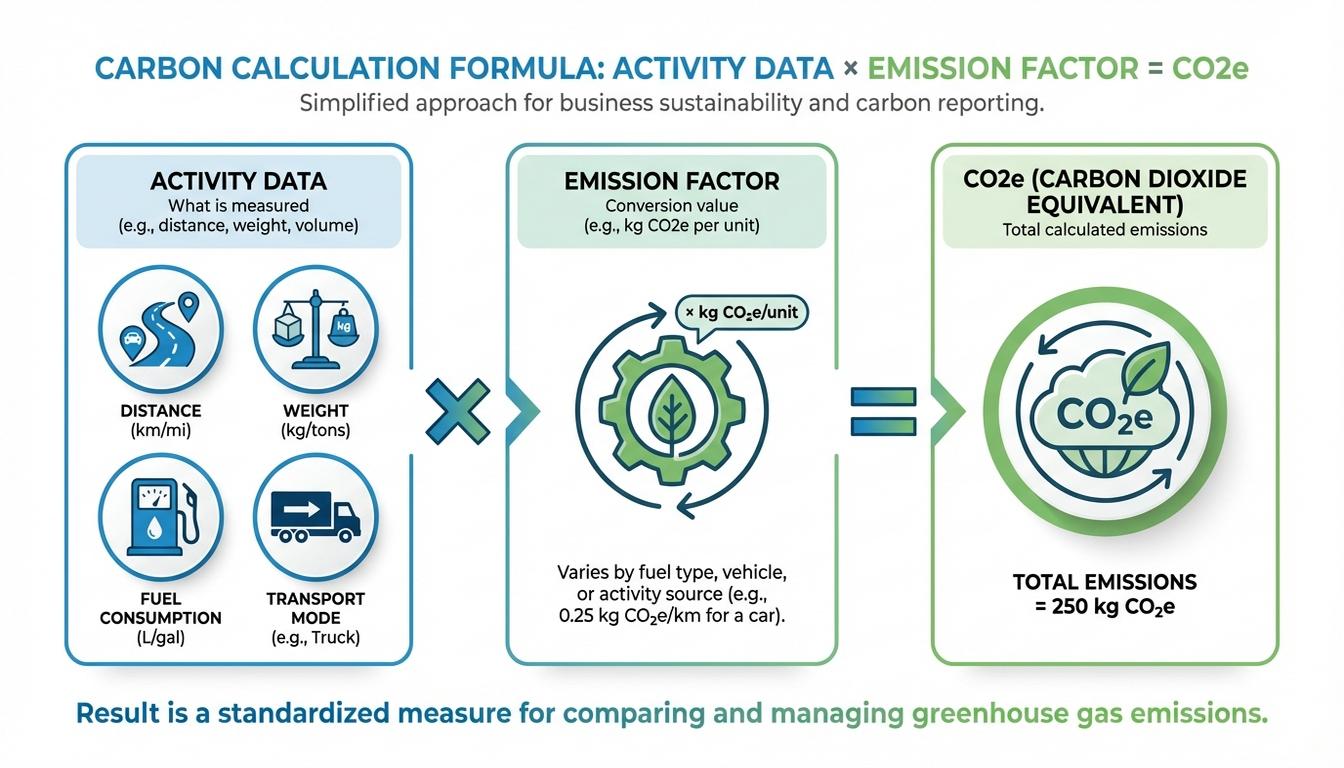

The Core Formula for Carbon Calculation

Let us get into the details of how the math actually works. You do not need a PhD in climate science to get started, but you do need clean data. Most accurate logistics carbon calculations follow a standard logic: Activity Data multiplied by an Emission Factor. This yields the total CO2 equivalent (CO2e) for that specific activity.

Step 1: Gather Activity Data

- Distance: Total miles or kilometers traveled per shipment.

- Weight: Tonnage or mass of the freight.

- Mode: The specific vehicle type, such as a 40 tonne diesel truck or a wide body cargo aircraft.

- Fuel Consumption: This is the gold standard of data. If you have the exact liters or gallons of diesel used, your calculation will be significantly more accurate than using averages.

Step 2: Apply Emission Factors

Emission factors are standardized values that represent the amount of GHG emitted per unit of activity. For example, you might use a factor that tells you how many kilograms of CO2 are emitted per ton-kilometer of rail freight versus air freight. Many reporting tools draw these factors from agencies like the Intergovernmental Panel on Climate Change (IPCC).

Step 3: Allocation

This is where it gets practical. If you have one truck carrying goods for five different customers, you must allocate the emissions fairly. This is usually done based on the weight or volume each customer occupies. The practical takeaway is to standardize this allocation method across your entire network to ensure your year over year comparisons are valid.

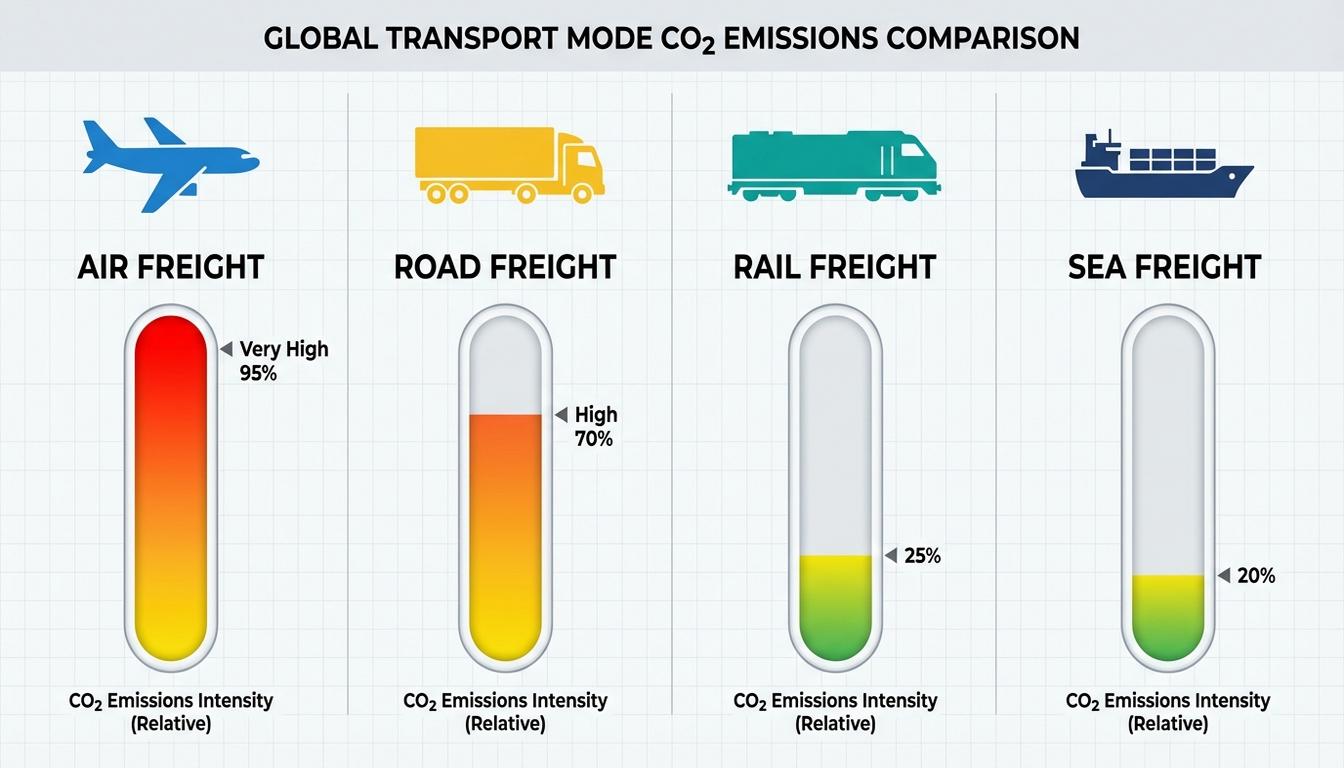

The Impact of Transport Modes on Your Footprint

When it comes to logistics carbon footprint, the mode of transport you choose is the single biggest lever you can pull. The differences in emissions intensity between modes are staggering. This is exactly what you need to know if you are looking to make an immediate impact on your numbers.

Road freight is typically the largest source of logistics CO2 because of our heavy reliance on diesel and the sheer volume of trucks on the road. In the U.S., truck freight alone emitted about 392 million metric tons of CO2 in 2023. By 2025, that number is forecast to rise to around 420 million metric tons. Texas and California remain the most emissions intensive states due to their roles as massive logistics hubs.

What is the actual answer for companies looking to cut these numbers? Look at rail and intermodal. A single intermodal train can move the load of about 280 trucks. Industry data shows that using intermodal rail instead of long haul trucking can reduce your carbon footprint by around 60% on those specific lanes. Air freight, while fast, is the opposite extreme. It has the highest emissions intensity per ton-kilometer and should be reserved for only the most time critical or high value goods.

So what does this mean for you? Your next step is to conduct a modal audit. Identify lanes where speed is less critical and move that freight to rail. This shift alone can do more for your sustainability targets than almost any other operational change.

Using Real-Time Visibility for Accurate Tracking

The real question is, are you using static averages or real-time data? Traditional carbon accounting relies on “post-game” analysis, looking back at invoices and distance averages. While this is a good starting point, it lacks the precision needed for modern optimization. This is where it gets practical: Digital emissions tracking.

Modern platforms integrate telematics, GPS, and IoT sensors to calculate emissions in near real time. Why does this matter? Because real world conditions change your footprint. A truck stuck in three hours of traffic at a port is emitting significantly more than a truck moving at highway speeds. According to industry visibility experts, access to shipment level data allows you to manage what you measure.

Here is what that actually looks like in practice:

- Identifying Idling: Monitoring dwell times at warehouses helps you reduce unnecessary fuel burn.

- Route Optimization: Companies using data driven routing can cut transportation emissions by 20% to 30%.

- Condition Monitoring: For cold chains, if a shipment of pharmaceuticals or food is spoiled due to temperature excursions, you have to ship a replacement. That doubles the carbon footprint of that order.

The action item here is simple. If you are serious about accuracy, move away from spreadsheets and toward integrated transport management systems (TMS) that capture real time telemetry. This data provides the granular detail needed to prove your progress to stakeholders.

The Hidden Cost of Empty Miles

Here is the thing most people miss: The carbon cost of nothing. We are talking about empty backhauls, where a truck returns from a delivery with an empty trailer. This is a massive source of waste in the logistics industry.

Let us look at this closely. An empty truck trip can emit roughly 404 grams of CO2 per mile while generating zero revenue. This is pure waste. Your best move here is to focus on load consolidation and backhaul coordination. By matching your shipments with available capacity from other carriers or using digital freight matching platforms, you can eliminate these “ghost” emissions.

UPS provides a famous example of this in action. Their ORION route optimization platform saves around 10 million gallons of fuel per year. They did not do this just by driving less, they did it by driving smarter. They minimized left turns and optimized the sequence of stops to ensure the vehicle was utilized as efficiently as possible throughout its route.

Measuring Warehouse and Cold Chain Impact

While transport gets most of the attention, the buildings where goods sit are a vital part of your carbon accounting. Warehousing and material handling contribute to the 11% global logistics emission figure. This includes building energy use for heating, cooling, lighting, and the electricity used by automated sortation systems.

Cold storage is particularly energy intensive. The refrigeration required for food and medicine is a constant draw on the grid. On top of the energy used, there is the indirect impact of waste. Food waste alone is estimated to cause about 8% to 10% of global greenhouse gas emissions. If your logistics processes allow food to spoil, your footprint is far larger than just the fuel used to transport it. For specific strategies on reducing building impact, see our warehouse energy efficiency tips.

One way to mitigate the warehouse footprint is through smarter design. This might mean installing LED lighting, high efficiency HVAC systems, or rooftop solar panels. Additionally, how you pack those goods matters. Using sustainable packaging solutions can reduce the weight and volume of shipments, which indirectly lowers the energy needed for both storage and transport.

Quick Reference: Logistics Carbon Footprint Metrics

- Global Logistics Contribution: Up to 11% of all GHG emissions.

- Intermodal Advantage: Up to 60% reduction in CO2 compared to long haul trucking.

- Empty Mile Cost: Approximately 404 grams of CO2 per mile.

- Optimization Potential: 20% to 30% reduction in emissions through data driven routing.

- US Heavy Truck Forecast: Projected 420 million metric tons of CO2 by 2025.

- Top Emitting States: Texas and California (due to high freight volume and ports).

- Food Waste Impact: 8% to 10% of global GHG emissions, often linked to poor cold chain logistics.

Common Questions About Logistics Carbon Footprint

How do I start calculating emissions if I don’t have fuel data?

The direct answer is to use distance based calculations. You take the total distance traveled, multiply it by the weight of the cargo, and apply a standard emission factor for that specific mode of transport. While less precise than fuel based data, it is a globally recognized starting point for Scope 3 reporting.

Is air freight ever a sustainable option?

In terms of carbon intensity, the answer is almost always no. Air freight emits significantly more CO2 per ton-kilometer than any other mode. However, for extremely high value, life saving medical supplies where time is the only factor, it may be the only operational choice. In these cases, companies often look to carbon offsets or Sustainable Aviation Fuel (SAF) to mitigate the impact.

What is the difference between CO2 and CO2e?

This is a detail that changes everything for your reporting. CO2 refers specifically to carbon dioxide. CO2e stands for “carbon dioxide equivalent,” which includes other greenhouse gases like methane and nitrous oxide, weighted by their global warming potential. Always aim to report in CO2e to provide a complete picture of your environmental impact.

How does electrification impact my logistics footprint?

Electrification can substantially lower your emissions, especially for last mile delivery and regional trucking. However, the true benefit depends on your local power grid. If your electric vans are charged with power from a coal plant, the reduction is smaller than if they are charged with wind or solar energy. Even so, electric motors are generally more efficient than internal combustion engines.

Next Steps for Your Carbon Strategy

Measuring your logistics carbon footprint is no longer a “nice to have” activity. It is a fundamental requirement for modern supply chain management. The data is clear: freight demand is growing, and the pressure to decarbonize is mounting. By focusing on high quality activity data, shifting to lower intensity modes like rail, and using real time visibility to eliminate waste, you can create a more resilient and sustainable operation.

The practical takeaway is to start where you are. Begin with distance based calculations for your largest lanes, then gradually move toward real time fuel and telematics data. Work closely with your carriers to ensure they are providing the transparency you need. As regulations tighten and customers demand greener solutions, having an accurate, data driven understanding of your footprint will be your greatest competitive advantage. Ready for the specifics? Your first action should be to audit your top ten shipping lanes for intermodal potential. Small shifts in how you move goods can lead to massive reductions in your total carbon impact.