Improving Warehouse Energy Efficiency and Cutting Costs

Looking for the exact breakdown of how to handle warehouse energy efficiency? You have come to the right place. While general guides cover the basics of running a business, you need the specific details that actually help you lower utility bills and meet modern sustainability standards. We are going to get straight into what works, what does not, and exactly what you should do to optimize your facility. Let us get specific.

You probably already know that utility costs are rising and that “going green” is a major corporate priority. However, you are likely looking for the detailed breakdown of where your energy is actually going and which upgrades provide the fastest return on investment. This is not just about swapping a few lightbulbs. It is about a structural shift in how we design and operate industrial spaces. For a complete overview of the broader industry transition, check out our main guide on this sustainable logistics guide. Now, let us look closely at the technical details that change your bottom line.

The Real Energy Profile of a Modern Warehouse

Before we can fix the problem, we have to understand where the power is going. The energy profile of a warehouse depends heavily on what you are storing. For a typical non-refrigerated dry warehouse, heating and lighting are the heavy hitters. Together, they account for about 76 percent of total energy demand. Cooling systems usually add another 14 percent to that total. In these facilities, you are looking at an average consumption of 6.1 kWh of electricity and 13,400 Btu of natural gas per square foot every year.

Cold storage is a completely different animal. In these environments, refrigeration can consume up to 60 percent of the total electricity use. The intensity is much higher, and the margin for error is much smaller. Here is the thing most people miss. Small inefficiencies in a dry warehouse are annoying, but in a cold storage facility, they are financial leaks that can sink your operational budget. Understanding your specific baseline is the first step toward any real improvement.

The U.S. Energy Information Administration projects that warehouse floor area will grow by about 6 billion square feet in the next 30 years. According to the U.S. Energy Information Administration (EIA), warehouses are already the second most common commercial building type in the country. This expansion means that energy efficiency is no longer a niche concern. It is a core component of staying competitive in a crowded market.

The practical takeaway is simple. You must audit your current consumption based on your specific storage type. If you are running dry storage, focus on the lights and the heater. If you are running cold storage, your focus must be 100 percent on the refrigeration cycle and the building envelope.

Maximizing LED Warehouse Lighting and Controls

When it comes to warehouse energy efficiency, lighting is often the “low-hanging fruit.” Replacing conventional high-intensity discharge or fluorescent fixtures with LED warehouse lighting can reduce your lighting energy consumption by up to 75 percent. This is one of those rare cases where the upgrade pays for itself almost immediately. LEDs do not just use less power. They also provide better light quality and last significantly longer, which means fewer maintenance disruptions for your team.

Let us get into the details of controls. Simply switching to LEDs is only half the battle. To see the best results, you need to integrate motion and occupancy sensors. In a massive facility, you often have aisles that are empty for 80 percent of the day. Why are those lights on at full blast? Sensors allow you to zone your lighting so that only active picking areas are illuminated. This is where it gets practical. You can also use daylight sensors near skylights or clerestory windows to dim the LEDs when natural light is sufficient.

Here is what works and what does not in lighting:

- Works: Zoning your lighting based on shift schedules and picking frequency.

- Works: Using instant-on LEDs that do not require a warm-up period.

- Does not work: Leaving high-bay lights on in low-traffic storage zones “just in case.”

- Does not work: Ignoring the maintenance savings of LEDs when calculating your ROI.

Your best move here is to conduct a lighting audit. Look for “dead zones” where lights stay on despite zero activity. If you are still using HID lamps, you are essentially burning money every time you flip the switch. The technology has advanced to the point where an LED retrofit is a standard operational requirement.

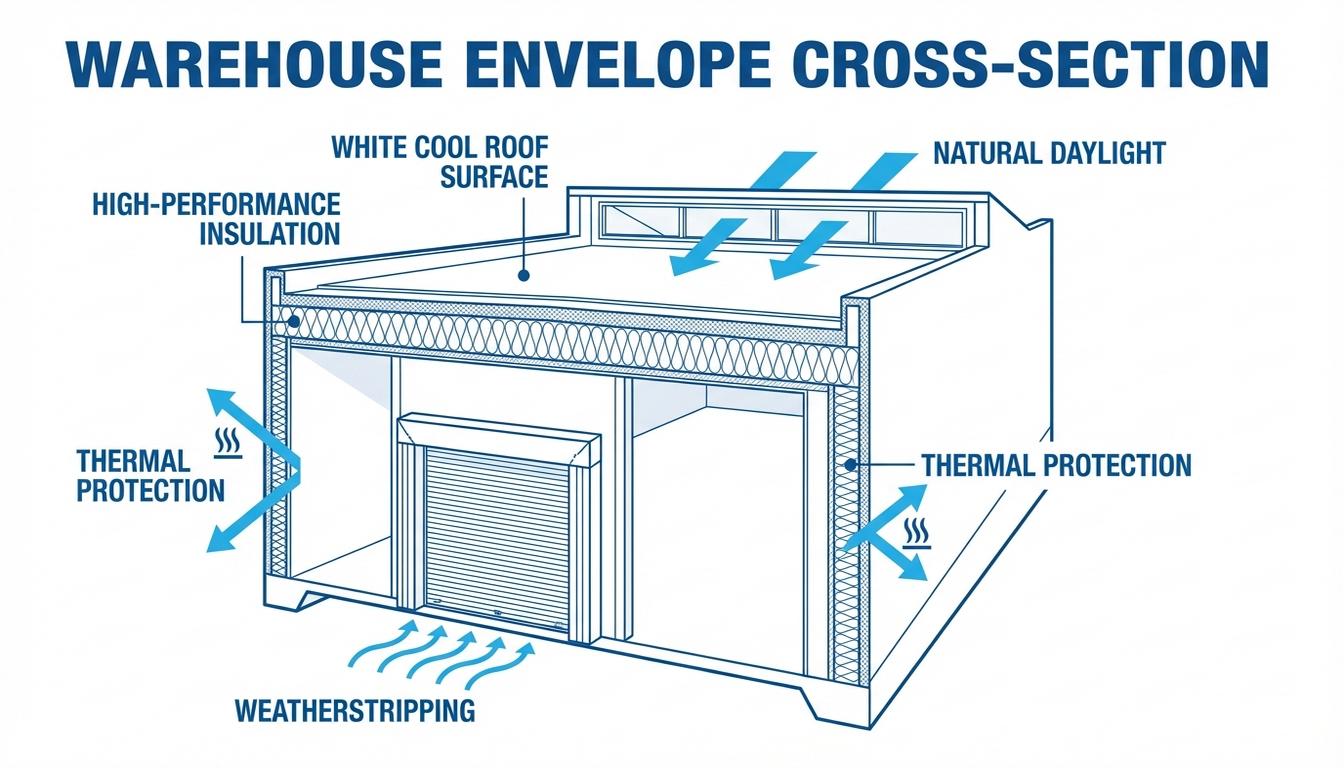

Sustainable Warehouse Design and the Building Envelope

This is where we talk about the “skin” of your building. Sustainable warehouse design starts with the envelope. If your walls and roof are leaking air, your HVAC system is working overtime for no reason. In refrigerated facilities, this is critical. Improving wall and roof insulation, sealing infiltration paths, and upgrading loading dock doors can drastically reduce your heating and cooling loads. Many modern facilities are now using “cool roofs” with high-albedo surfaces that reflect solar heat rather than absorbing it.

Have you considered using natural light? Clerestory windows and translucent roof panels can provide enough daytime illumination to keep your lights off for hours at a time. This is one of the most effective energy reduction strategies available. When you combine natural daylighting with automatic dimming controls, the savings stack up quickly. Research from the National Renewable Energy Laboratory (NREL) shows that even modest efficiency improvements in the building shell can make a facility much easier to power with renewables later.

So what does this mean for you? If you are planning a new build or a major renovation, look at these specific areas:

- Insulation levels: Go beyond the minimum building code requirements.

- Dock seals: Use high-quality seals and rapid-closing doors to prevent air exchange.

- Thermal mass: Use materials that help stabilize indoor temperatures naturally.

- Airtightness: Conduct a pressure test to find hidden leaks in the building’s seams.

The practical takeaway is that the more “passive” your building is, the less you have to pay for “active” climate control. It is much cheaper to keep the heat out in the first place than it is to pump it out with a cooling system. To see how these physical improvements impact your overall environmental data, you might want to look at how to logistics carbon footprint measure accurately.

Advanced HVAC and Climate Control Strategies

Once the building envelope is secure, we need to talk about the machinery inside. Standard HVAC systems in many warehouses are outdated and oversized. Smart climate control is the key here. These systems use sensors to optimize heating and cooling based on occupancy, shift schedules, and even real-time weather data. Instead of keeping the entire 200,000-square-foot facility at exactly 68 degrees, you can use demand-controlled ventilation to focus on the areas where people are actually working.

One detail that changes everything is air distribution. We see a lot of facilities with massive temperature stratification, where all the warm air is trapped at the ceiling while the floor remains cold. This is a waste of energy. Destratification fans can push that warm air back down to the work zones, reducing the load on your heaters. We have also seen great results from using computational fluid dynamics to model air circulation. This allows you to place vents and fans in the most efficient locations possible.

The short version is that your HVAC should be as dynamic as your operations. If your heaters are running while the loading dock doors are wide open, you have a control problem. Modern systems can be programmed to shut down or throttle back the moment a dock door is opened. Your next step is to look into variable-speed fans and high-efficiency heat pumps, which can drastically outperform traditional gas-fired furnaces.

The Role of Thermal Mass

In many climates, the concrete slab of your warehouse acts as a massive thermal battery. By cooling the facility slightly more than necessary during the night when electricity prices are lower, you can “charge” that thermal mass. During the day, the concrete releases that coolness, reducing the need for peak-hour air conditioning. This is the kind of specialized expertise that separates a standard warehouse from a truly energy-efficient one.

Automation, Robotics, and Process Optimization

There is a fascinating trend happening in the world of energy management warehouse operations. As we add more automation and robotics, the energy profile shifts. Instead of using energy for HVAC to keep humans comfortable, we use it to power material-handling equipment. In heating-dominated climates, this can actually be an advantage. High-density automated storage and retrieval systems allow you to operate in smaller, less conditioned spaces. Robots do not need the same light levels or temperature ranges that humans do.

Let us get into the details of how robots help in cold storage. Because robots can operate in extremely low temperatures without breaks, you can minimize human presence in the coldest zones. This allows for fewer door openings and more stable temperatures. Faster robotic retrieval also means that doors are open for shorter periods, cutting refrigeration energy significantly. This is a massive win for both productivity and sustainability.

Even without robots, you can save energy through layout optimization. Here is what that actually looks like. By reducing the travel distance for your forklifts and conveyors through better slotting, you use less electricity per order. Mathematical models have shown that optimized sorting and picking operations can reduce energy consumption by more than 20 percent in some cases. It turns out that efficiency in labor and efficiency in energy are often the same thing. This is also a great time to evaluate your materials, such as looking into sustainable packaging solutions that might be lighter or more space-efficient, further reducing the load on your systems.

The action item here is to review your warehouse management system data. Are your most popular items located as close to the shipping dock as possible? If not, you are wasting energy on every single pick. Small tweaks to your warehouse layout are practically free and yield immediate energy reduction results.

Solar Warehouses and the Path to Net-Zero

If you have a large, flat roof, you are sitting on a gold mine of renewable energy. Warehouses are the perfect candidates for rooftop solar PV because they have a massive surface area relative to their energy needs. A solar warehouse can often reach zero-energy building status with surprisingly modest efficiency upgrades. NREL modeling suggests that covering just 50 percent of a typical warehouse roof with solar panels can be enough to offset the entire building’s annual energy use.

This is where it gets practical for your business case. The cost of solar technology has dropped, while the pressure for corporate climate targets has increased. Major brands like Amazon and Walmart are already moving toward 100 percent renewable energy. If you are a third-party logistics provider, having a solar-powered facility could be the specific detail that wins you a contract with a sustainability-minded client.

Ready for the specifics on going solar?

- Grid-interactive operation: You can use on-site battery storage to save solar power for the evening or to provide power during peak demand periods when rates are highest.

- Net-zero goals: By combining LED retrofits, smart HVAC, and solar, you can transform an old facility into an ultra-high-efficient building.

- Resilience: On-site power and storage protect your operations from grid outages, which is a massive competitive advantage.

The real question is not if you should install solar, but when. With current tax incentives and the decreasing cost of equipment, the payback periods for solar warehouses are shorter than ever. It is the final piece of the puzzle for any comprehensive energy management strategy.

Quick Reference: Warehouse Efficiency at a Glance

- Lighting: Switch to LEDs with motion sensors for up to 75% energy reduction.

- Building Envelope: Use high-albedo “cool roofs” and seal all loading docks.

- HVAC: Implement destratification fans and demand-controlled ventilation.

- Refrigeration: Use robotics in cold zones to minimize door openings and human heat load.

- Operations: Optimize travel routes to reduce forklift and conveyor run time.

- Solar: Aim to cover 50% of your roof to reach near-zero energy status.

- Management: Use sub-metering to track exactly where your power is going.

Common Questions About Warehouse Energy Efficiency

What is the most effective first step for energy reduction?

The answer is almost always a lighting retrofit combined with smart controls. Because lighting accounts for a massive chunk of dry warehouse energy use, and LED technology is so efficient, this provides the fastest return on investment and the most noticeable change in your utility bills.

How does automation affect energy use?

Automation shifts the load. You will use more energy on material-handling equipment but significantly less on HVAC and lighting. In many cases, especially in extreme climates, the net result is a significant decrease in total energy consumption because robots can work in environments humans cannot.

Can an older warehouse really become net-zero?

Yes, and it is easier than you might think. Because warehouses are low-rise buildings with large roofs, they have a very high “solar-to-floor-area” ratio. When you combine standard efficiency upgrades like insulation and LEDs with rooftop solar, reaching a net-zero balance is a very realistic goal for existing structures.

Why is sub-metering important?

The short version is that you cannot manage what you do not measure. Most warehouses only have one main meter. By installing sub-meters on your HVAC, lighting, and specialized equipment, you can identify “energy vampires” and see exactly which upgrades are working. This data is essential for justifying future capital investments.

When it comes to warehouse energy efficiency, the details truly matter. We have seen that a combination of building design, smart lighting, and optimized operations can cut energy use by 5 to 20 percent almost immediately. For larger investments like solar or advanced automation, the payoffs extend far beyond just the utility bill. They improve your brand value, your worker comfort, and your long-term operational resilience. The practical takeaway is that every square foot of your warehouse is an opportunity to save money and reduce your carbon footprint. Start with an audit, pick the high-ROI projects like LED lighting, and build a roadmap toward a more sustainable and profitable future.