Supply Chain vs Value Chain: Understanding the Key Differences

Looking for the exact breakdown of supply chain vs value chain? You have come to the right place. While general guides often blur these two terms, you need the specific details that actually help you distinguish between operational efficiency and strategic value. We are going to get straight into what works, what does not, and exactly how these two concepts interact to drive your business forward. Let us get specific.

If you are reading this, you probably already know that both terms involve moving products to customers. However, you are looking for the detailed breakdown, not the surface-level overview.

The Core Definitions: Supply Chain and Value Chain

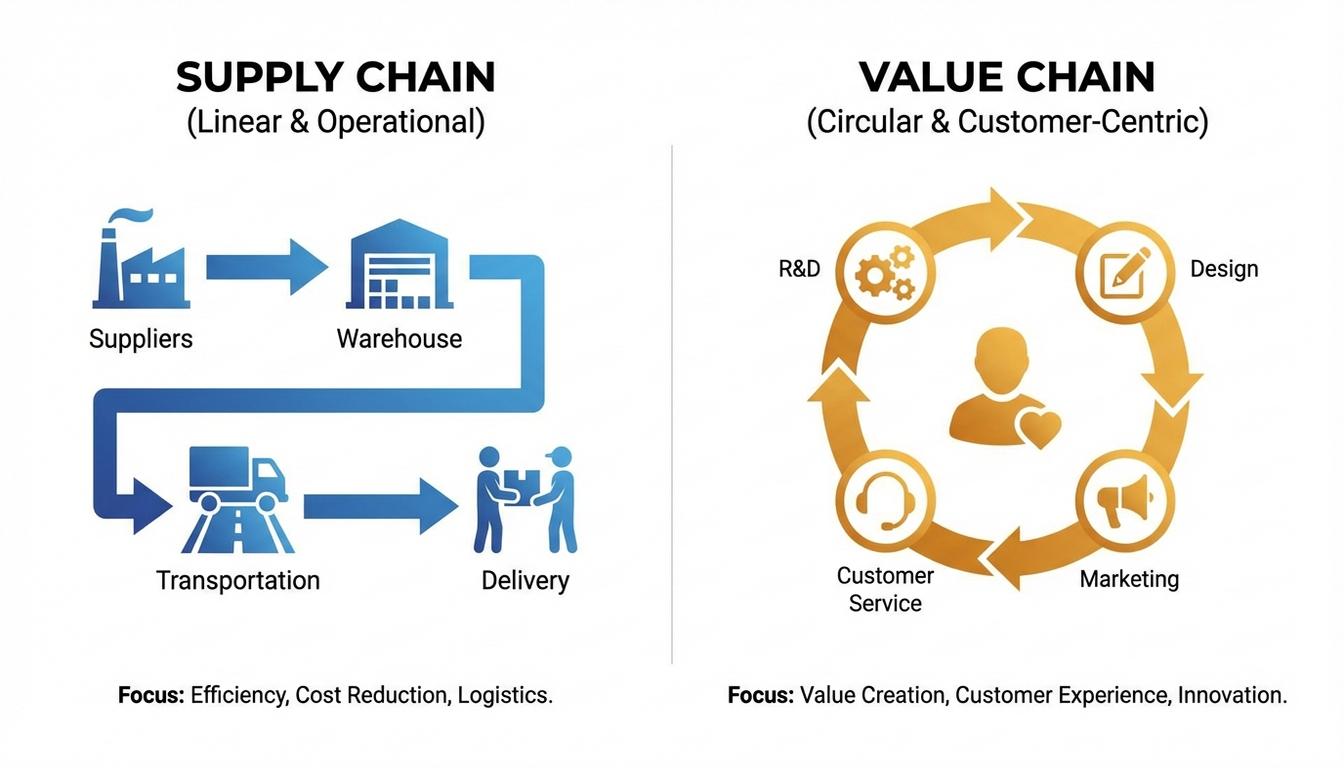

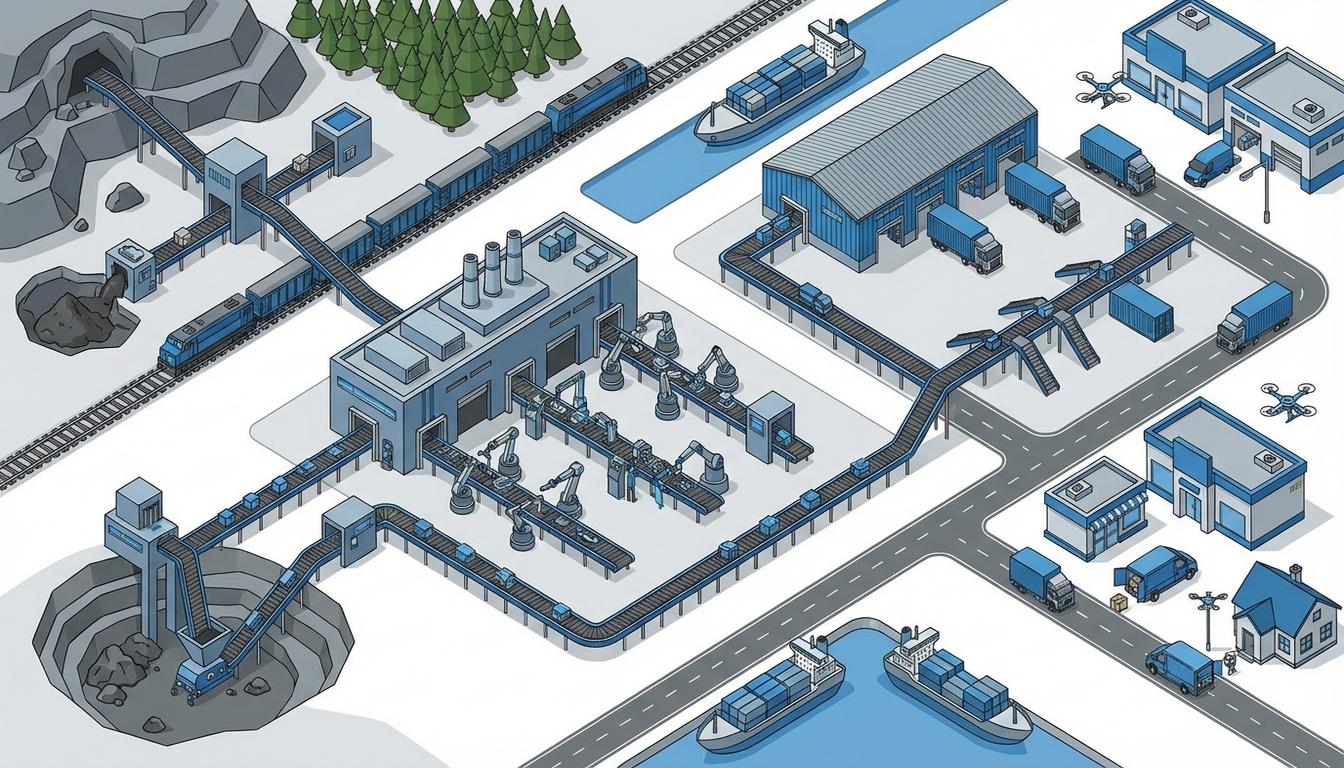

To understand the difference, we have to start with the fundamental purpose of each concept. A supply chain is the network of organizations, people, and resources involved in moving a product from raw materials to the final customer. It is a physical and tangible process. When we talk about supply chains, we are talking about sourcing, manufacturing, warehousing, and transportation. The goal is efficiency. We want to minimize cost, ensure reliable availability, and optimize lead times. It is essentially about the how of building and moving the product.

The value chain is different. It is a series of activities a company performs to design, produce, market, deliver, and support its products with the aim of creating value for customers. Michael Porter formalized this concept in his 1985 book, Competitive Advantage. He framed it as a tool for analyzing how each activity contributes to a firm’s overall margin. While the supply chain focuses on the flow of materials, the value chain focuses on the creation of a competitive advantage. It asks how we can make the customer more willing to pay for what we offer.

The direct answer is that one is about cost and the other is about value. Supply chains are modeled from the suppliers forward. Value chains conceptually start with the customer and work backward. Here is the specific situation where this applies. If you are trying to cut costs in your warehouse, you are looking at your supply chain. If you are trying to figure out why a customer chooses your brand over a competitor, you are looking at your value chain.

Key Differences: Scope, Focus, and Objectives

When it comes to supply chain vs value chain, the details matter. Most people get them confused because they overlap in the middle. But their scopes are actually quite different. Let us get into the details of these distinctions.

Operational Execution vs. Strategic Value Creation

The supply chain is focused on operational execution. We are looking for the most efficient way to get a box from point A to point B. This involves managing supply chain visibility strategies to ensure we know where our inventory is at all times. The focus is on physical flows. We monitor assets, facilities, and transport. If the trucks are moving and the shelves are full, the supply chain is doing its job.

The value chain is strategic. It covers all activities that create value, including Research and Development (R&D), product design, branding, and customer experience. It is not just about logistics. It is about how the design of the product makes it more desirable. It is about how the marketing makes the product feel premium. The value chain is an analytical framework used to evaluate how activities build a brand. This is one of those areas where getting it right makes a real difference.

Starting Points and Flow Directions

The supply chain usually starts with raw materials. We look at the supplier, then the manufacturer, then the distributor. It is a forward-moving process. We are pushing materials through a system to reach an end point. Efficiency here is measured by how quickly and cheaply we can complete that push. Your best move here is to focus on reducing friction in the flow of goods.

The value chain starts with the market. We ask what the customer needs and what they value. Then we work backward to see which activities can provide that value. Does the customer want faster delivery? Does the customer want sustainable materials? Once we know the answer, we adjust our activities to meet those needs. This backward-looking approach ensures that every step we take adds something that the customer is actually willing to pay for.

Primary Objectives and Metrics

What is the actual answer to how we measure success? For the supply chain, the primary objectives are lowering total cost and reducing waste. We look at specific supply chain KPIs such as cost per unit, fill rate, and inventory turnover. These metrics tell us if our logistics network is lean and reliable. We are looking for operational perfection.

For the value chain, the objectives are differentiation and margin. We want to increase the perceived value of the product. Metrics here include customer retention, brand equity, and Net Promoter Score (NPS). We are not just asking if the product arrived on time. We are asking if the customer was delighted by the experience. Here is the step-by-step breakdown of how these metrics differ:

- Supply Chain: Focuses on cost per order, lead time, and capacity utilization.

- Value Chain: Focuses on product margin, brand awareness, and customer lifetime value.

The practical takeaway is that you cannot manage a value chain with supply chain metrics alone. You need both to see the full picture of your business performance.

How Supply Chains and Value Chains Work Together

Are they independent systems? Not at all. Most modern organizations treat them as interdependent and complementary. A resilient supply chain is necessary for the value chain to function. If your supply chain fails to deliver, it does not matter how good your marketing is. You have destroyed the value you promised to the customer. This is exactly what you need to know about their relationship.

Supply chains provide the capabilities and reliability required to produce and deliver. The value chain defines where and how to add value. For instance, a company might decide to use sustainable, ethically sourced materials as a value chain strategy. To make this a reality, the supply chain must find those suppliers and ensure the materials are handled correctly. Without the supply chain, the value strategy is just an idea. Without the value strategy, the supply chain is just a utility.

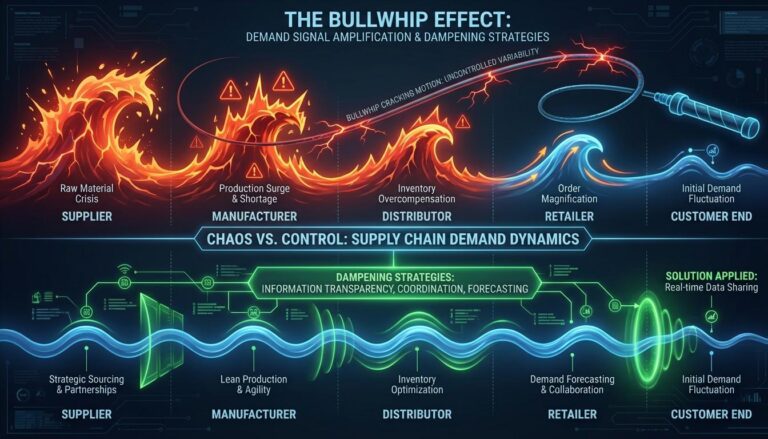

Consider the bullwhip effect in the supply chain. This phenomenon occurs when small fluctuations in demand cause large swings in inventory levels upstream. From a supply chain perspective, this is a logistics nightmare that increases costs. From a value chain perspective, it represents a failure to accurately capture and respond to customer needs. By integrating both views, you can create a system that is both efficient and highly responsive to the market.

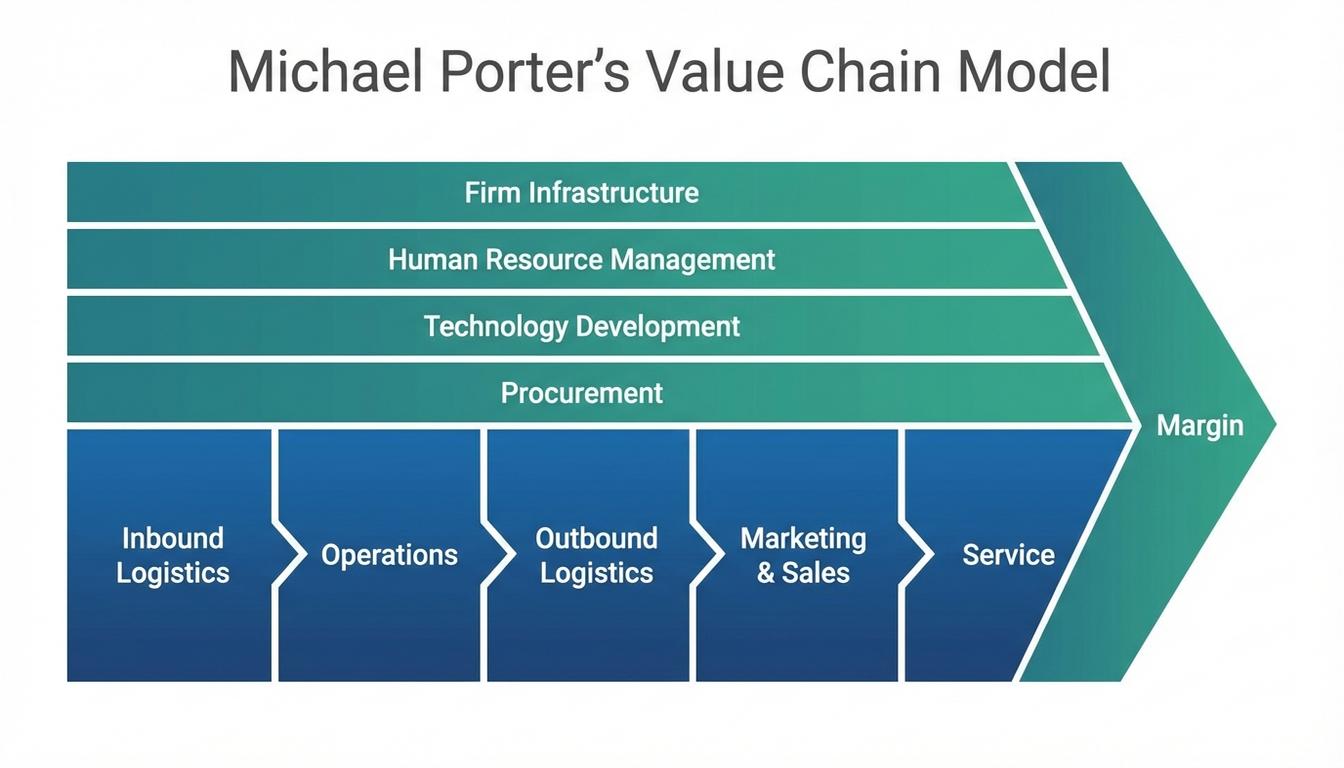

The Michael Porter Value Chain Model

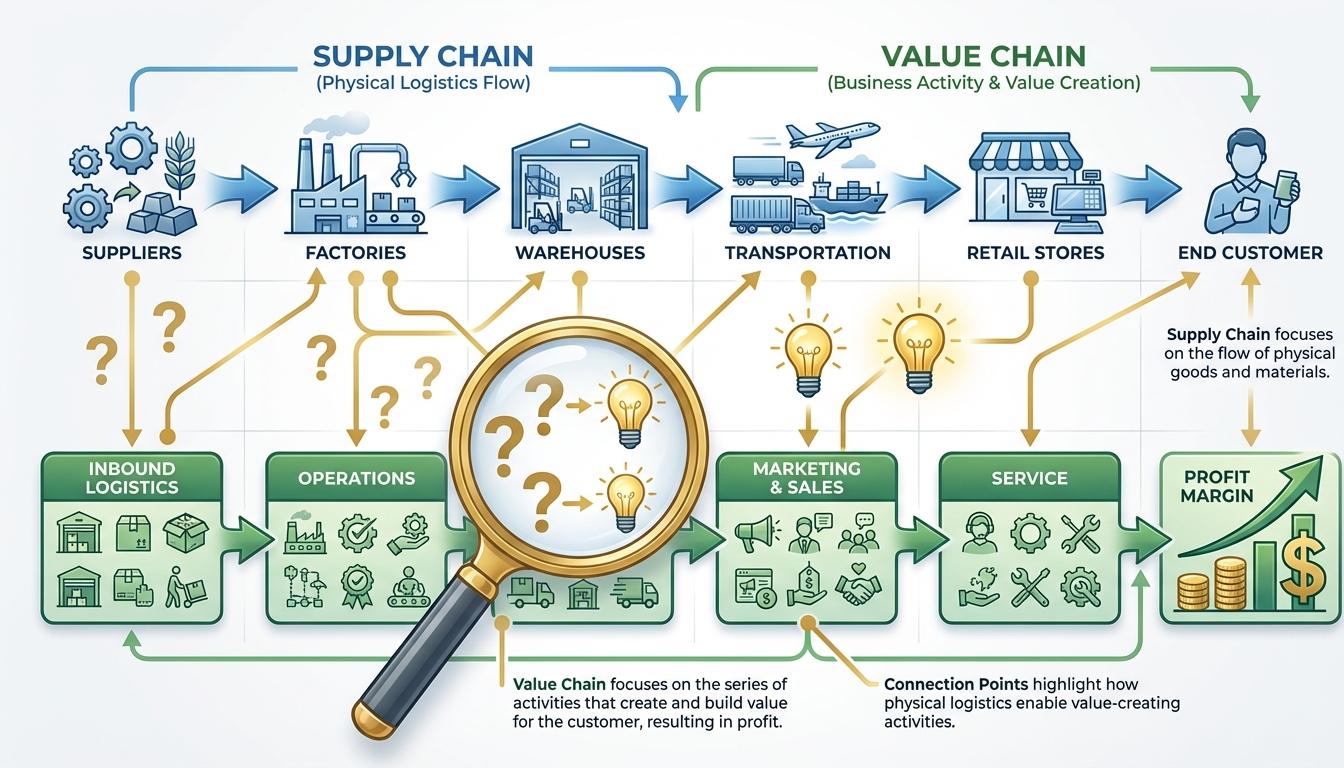

Let us look at this closely. Michael Porter’s model is the standard for value chain analysis. He divides activities into two categories: Primary and Support. Understanding these categories helps you see where the supply chain fits into the bigger picture. This is the detail that changes everything for your strategic planning.

Primary Activities

These are the activities directly involved in the creation and sale of the product. They include:

- Inbound Logistics: Receiving, storing, and distributing inputs. This is a core supply chain function.

- Operations: Transforming those inputs into the final product.

- Outbound Logistics: Collecting, storing, and distributing the product to buyers.

- Marketing and Sales: Activities that make the customer aware of the product and provide a reason to buy.

- Service: Activities that maintain the value of the product after it is sold, such as installation or repairs.

Support Activities

These activities provide the infrastructure that allows the primary activities to take place. They are often overlooked but are critical for competitive advantage. According to research from the Harvard Business Review, these support functions are where many modern firms find their edge. They include:

- Firm Infrastructure: Finance, legal, and general management.

- Human Resource Management: Recruiting, training, and development.

- Technology Development: R&D, process automation, and design.

- Procurement: The strategic sourcing of all inputs used in the value chain.

The action item here is simple. Use this model to map out your own organization. Identify which activities are purely about moving goods (supply chain) and which ones are about making those goods more valuable to the customer.

Real-World Examples of the Differences

To make this practical, let us look at two different industries. This will show you how the focus shifts depending on the business model. Ready for the specifics?

Example 1: A Premium Electronics Brand

For a high-end smartphone manufacturer, the supply chain tasks involve sourcing microchips globally and managing contract manufacturers in Asia. The goal is to keep costs down and ensure the phones are available for the global launch date. However, the value chain activities are what allow them to charge $1,000 for a phone. This includes the industrial design, the proprietary software ecosystem, and the premium retail experience in their flagship stores. The supply chain enables availability, but the value chain explains why customers wait in line for hours.

Example 2: A Large Grocery Retailer

In the grocery business, margins are thin. The supply chain is the hero here. The tasks involve purchasing from thousands of farmers, managing cold chain logistics for perishables, and delivering to hundreds of stores daily. Success is measured by reducing waste and keeping shelf prices low. On the value chain side, the retailer might focus on private-label strategies or a highly functional online ordering app. The supply chain yields lower prices, while the value chain design drives store loyalty and larger basket sizes.

When to Prioritize Supply Chain vs Value Chain

So which approach works best? It depends on your market. If you are in a highly competitive, low-margin sector like commodity manufacturing, your priority should be supply chain optimization. You need to be the most efficient player in the room. In this case, your strategy is built on cost leadership. You win by being faster and cheaper than the other guy.

If you are in a market where brand, innovation, and customer experience are the main drivers, you must focus on the value chain. This applies to technology, fashion, and luxury goods. You still need a solid supply chain, but it exists to serve your value goals. For example, you might choose a more expensive shipping method because it improves the unboxing experience for the customer. In this scenario, the value gained outweighs the supply chain cost. This is the real answer to how you should allocate your resources.

Quick Reference: Supply Chain vs Value Chain at a Glance

- Primary Focus: Supply chain is about flow and cost. Value chain is about margin and perceived value.

- Starting Point: Supply chain starts with suppliers. Value chain starts with customers.

- Core Goal: Supply chain aims for efficiency. Value chain aims for competitive advantage.

- Scope: Supply chain covers physical logistics. Value chain covers every activity from R&D to support.

- Key Framework: Supply chain uses SCM (Supply Chain Management). Value chain uses VCA (Value Chain Analysis).

- Common Metrics: Supply chain tracks lead times and inventory. Value chain tracks customer satisfaction and brand equity.

Common Questions About Supply Chain vs Value Chain

What is the main difference between a supply chain and a value chain?

The answer is simple. A supply chain focuses on the efficient movement of products from raw materials to the customer. A value chain focuses on the strategic activities that add value to those products, making them more desirable and profitable.

Is the supply chain part of the value chain?

Yes, most experts view the supply chain as a critical subset of the broader value chain. Activities like inbound and outbound logistics are part of the primary activities that Porter identified in his value chain model.

Why does the value chain start with the customer?

It starts with the customer because value is subjective. To create competitive advantage, a company must first understand what the customer is willing to pay for. Only then can they design their activities to meet those specific needs.

Can a company have a great supply chain but a poor value chain?

Absolutely. A company can be incredibly efficient at making and moving a product that nobody wants. This happens when a firm optimizes for cost but fails to innovate or brand effectively. They deliver efficiently but fail to capture margin.

Moving from Theory to Action

Now you have the specific answer you came for. The key point is that the supply chain and value chain are two sides of the same coin. One ensures you can deliver, while the other ensures you have something worth delivering. We have seen this question come up constantly, and the solution is to stop viewing them as separate departments. They are integrated functions that must align with your overall business goals.

Your next step is to evaluate your current operations. Are you measuring your logistics team solely on cost, or are you looking at how their performance affects the customer’s perceived value? For the bigger picture on how to align these elements, our complete guide on supply chain strategy covers everything else you need to know. The practical takeaway is to use supply chain optimization to build your foundation and value chain analysis to build your profit. Start by mapping your primary activities today.