Delivery Route Optimization: Strategies for Faster Deliveries

When you are managing a fleet, the pressure to perform is constant. You are likely dealing with tight margins, rising fuel prices, and customers who expect their packages to arrive exactly when promised. This is where delivery route optimization becomes your most valuable tool. It is not just about drawing lines on a map. It is the sophisticated process of using math and data to find the most efficient path for your drivers to take while balancing dozens of real-world restrictions.

If you have ever felt like your dispatchers are playing a never-ending game of Tetris with driver schedules and stop sequences, you are not alone. Most of us start with basic tools, but those manual methods quickly fall apart as the business grows. We are here to help you move beyond the basics. This guide covers the specific, high-level strategies needed to master your routing and keep your operations lean. For a broader look at the industry, you can check out our guide on last-mile delivery challenges and solutions to see how routing fits into the bigger picture.

So what does this mean for you? It means moving from a reactive state to a proactive one. We want to get you to a place where your routes are so tight that you are saving money on every single mile driven. Let us get into the details.

The Core Mechanics of Route Optimization

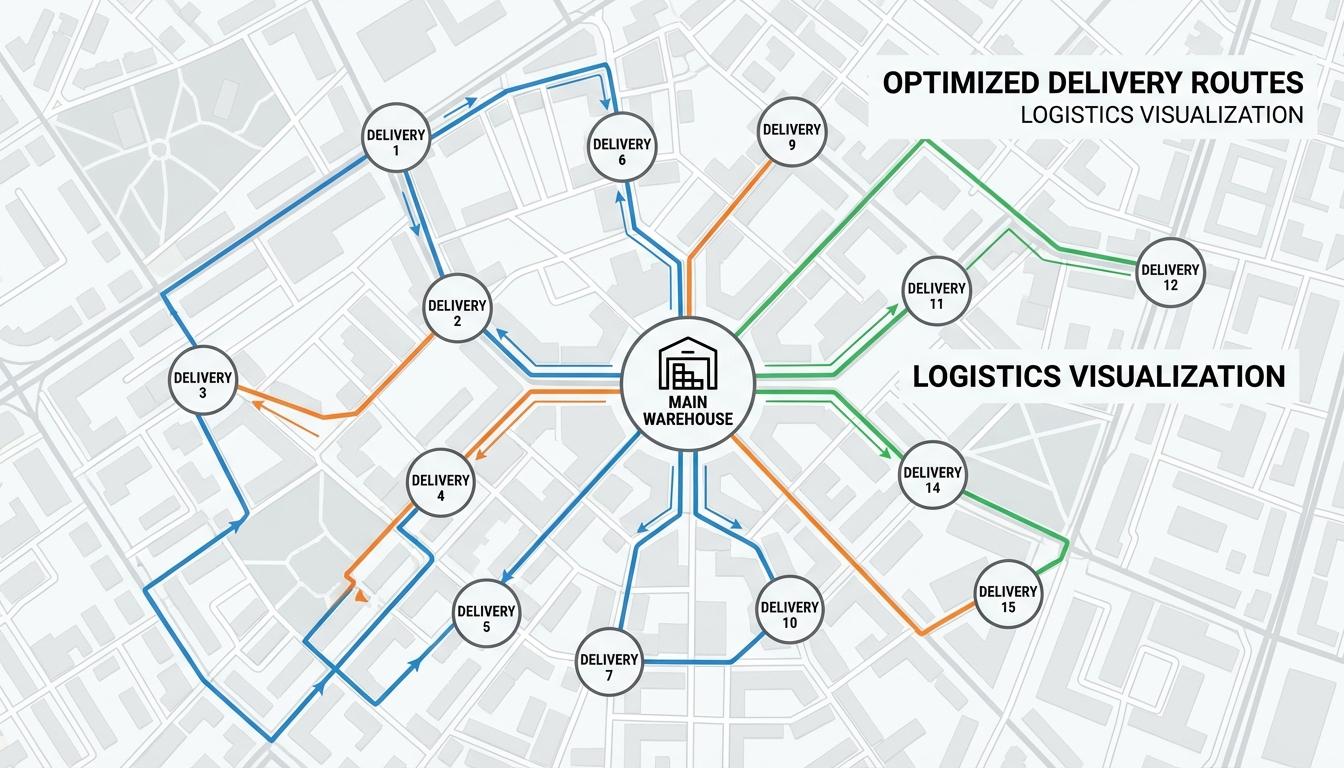

There is a reason this specific aspect confuses people. Many people use the terms route planning and route optimization interchangeably, but they are fundamentally different. Route planning is simply deciding how to get from point A to point B. Optimization is much more aggressive. It looks at the entire fleet and asks how we can serve 500 customers with 10 vehicles in the least amount of time, using the least amount of fuel, while honoring every customer’s 2-hour delivery window.

This is a specialized form of multi stop route planning. It relies on solving what mathematicians call the Vehicle Routing Problem (VRP). The first algorithmic solution to this was proposed back in 1959 by George Dantzig and John Ramser. They paved the way for modern delivery routing software to process billions of possible stop combinations in seconds. Without this technology, a human dispatcher is essentially guessing at the best sequence.

When it comes to vehicle routing, the software considers several critical inputs:

- Customer time windows and service-level agreements

- Vehicle capacity limits including weight and volume

- Driver working hours and required break times

- Road restrictions like bridge heights or weight limits

- Historical and real-time traffic patterns

The practical takeaway is that optimization seeks the “global” best for your fleet, not just the “local” best for one driver. Your best move here is to stop relying on driver intuition for stop sequencing. Even the most experienced driver cannot calculate the ripple effect that one delay has on twenty other stops. Let the algorithms do the heavy lifting so your drivers can focus on the road.

How Dynamic Routing Solves Real-World Chaos

Here is the specific situation where static planning fails. You send a driver out with a perfect morning plan. By 10:00 AM, there is a massive accident on the highway, two customers have cancelled their orders, and a new “emergency” pickup has been added to the queue. In a static environment, your plan is now useless. This is where dynamic routing saves the day.

Dynamic routing is the ability to adjust your active routes in real-time based on live data. Modern systems use GPS and mobile connectivity to feed information back to the central hub. If a vehicle is delayed by traffic, the system can autonomously reroute other drivers to cover the remaining stops. This level of route efficiency ensures that your commitments to the customer remain intact even when the day goes sideways.

The real question is, how does this impact your bottom line? When you can react to disruptions instantly, you significantly decrease the likelihood of missed windows. Reducing these errors is a key part of failed delivery reduction, as it prevents the costly “return to depot” scenarios that eat your profits. Ready for the specifics on how this works?

Integrating Real-Time Traffic Data

We are no longer limited to historical averages. Today, we pull live feeds from thousands of sensors and GPS units. According to research from the Institute for Operations Research and the Management Sciences (INFORMS), using real-time data can reduce total travel time by up to 15 percent in congested urban areas. This is the detail that changes everything for high-density delivery operations.

Handling Last-Minute Changes

The short version is that your software should be able to “insert” a new stop into an existing route without blowing up the schedule. It calculates the marginal cost and time of adding that stop to every available vehicle and picks the one with the lowest impact. This is exactly what you need to know if you are trying to offer same-day or on-demand services.

The Impact of AI and Machine Learning on Routing

Let us look at this closely. Traditional algorithms are great at following rules, but they struggle with nuances. This is where Artificial Intelligence (AI) and Machine Learning (ML) come into play. Instead of just looking at the distance between two points, AI analyzes historical data to see how long a delivery actually takes at a specific apartment complex at 3:00 PM on a Friday.

Machine learning models identify patterns that humans often miss. For example, a specific driver might consistently be faster at certain types of deliveries, or a specific loading dock might always have a twenty-minute wait. By feeding this data back into the delivery route optimization engine, the ETAs become incredibly accurate. This level of precision builds immense trust with your customers.

The action item here is simple. If you are shopping for software, ask if the system uses machine learning to refine its travel time estimates over time. A static system will stay exactly as accurate as it was on day one. An AI-driven system gets smarter and more efficient with every mile your drivers travel. This is how you stay ahead of the competition.

AI also helps with predictive analytics for demand forecasting. If you know that a certain neighborhood sees a 30 percent spike in volume every Tuesday, you can pre-emptively shift your fleet capacity. It moves you away from “putting out fires” and into a state of operational excellence. You want the real answer, not the surface-level stuff, and the answer is that data-driven routing is the only way to scale effectively.

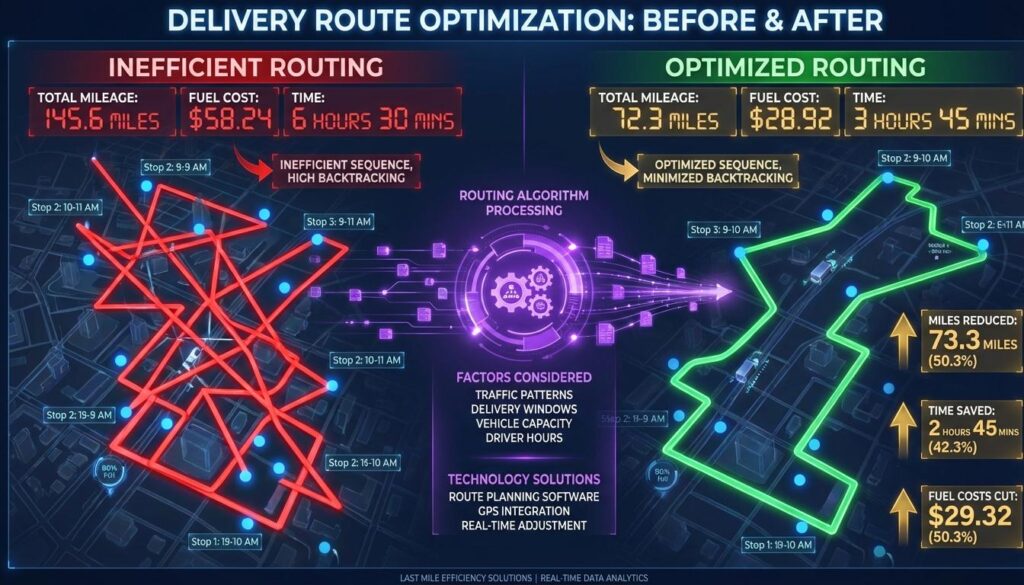

Reducing Operational Costs Through Route Efficiency

Let us cut to what matters. You are in business to make money, and route efficiency is the fastest way to lower your overhead. Every mile you do not drive is money back in your pocket. This is not just about fuel, though fuel is a massive part of it. It is about the wear and tear on your vehicles and the labor costs associated with every hour a driver is on the clock.

When we optimize routes, we are aiming for higher drop density. This means more stops per mile. According to the U.S. Environmental Protection Agency (EPA), reducing idling and optimizing routes are primary ways for fleets to lower their carbon footprint while simultaneously cutting costs. It is one of those rare situations where the green choice is also the most profitable choice.

Consider the following ways optimization saves you money:

- Reduced Fuel Consumption: Shorter paths and less time spent idling in traffic.

- Lower Maintenance Costs: Fewer miles means longer intervals between oil changes, tire replacements, and brake jobs.

- Optimized Labor: Drivers can finish their routes faster, reducing overtime pay or allowing them to take on more deliveries per shift.

- Fleet Right-Sizing: Often, businesses find they can complete the same number of deliveries with one or two fewer vehicles once their routes are truly optimized.

Here is what works and what does not. Trying to save money by cutting corners on driver safety or vehicle maintenance is a losing game. However, saving money by simply driving smarter is a sustainable, long-term strategy. Your next step is to audit your current mileage and compare it to the theoretical minimums provided by an optimization tool. The gap between those two numbers is your potential profit.

Best Practices for Implementing Optimization Strategies

Now for the part you actually came here for. How do you actually put this into practice? Transitioning from manual planning to high-level delivery routing software requires a clear strategy. You cannot just flip a switch and expect everything to be perfect. You need to manage the human element as much as the technical one.

First, ensure your data is clean. If your customer addresses are incorrect or your vehicle capacities are wrong, the software will produce “optimized” routes that are impossible to complete. The phrase “garbage in, garbage out” has never been more true than in the world of logistics. Before you start, spend time cleaning up your database.

Second, get your drivers on board. Drivers are often skeptical of new technology, especially if it changes the routes they have been driving for years. Show them how the software makes their day easier by reducing stress and ensuring they get home on time. When they see that they are no longer fighting impossible schedules, their buy-in will increase significantly.

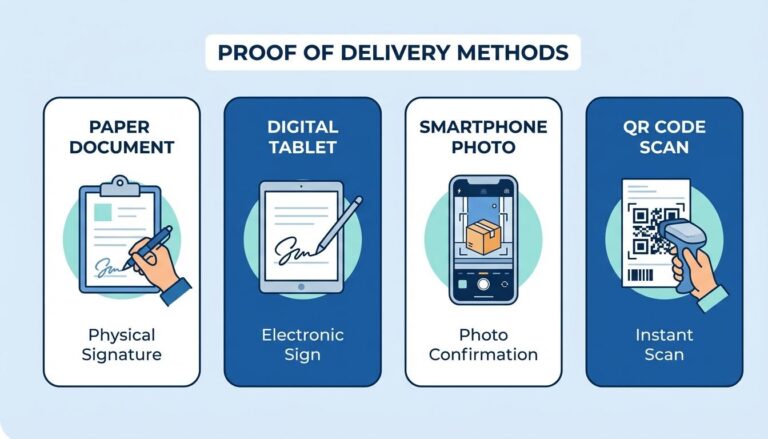

Finally, you must close the loop on your data. This is where proof of delivery methods become essential. By capturing data at the point of delivery, you can verify if the optimized plan was actually followed. This feedback loop allows you to refine your constraints and make the next day’s plan even better. Here is the step-by-step breakdown for a successful rollout:

- Baseline your current performance: Record your miles per stop, cost per delivery, and on-time percentage.

- Clean your data: Verify addresses, time windows, and vehicle specs.

- Run a pilot: Test the optimization on a small portion of your fleet first.

- Gather feedback: Listen to your dispatchers and drivers about where the system succeeds or fails.

- Adjust and scale: Tweak your constraints based on pilot results and roll it out to the full fleet.

Quick Reference: Route Optimization at a Glance

- Core Goal: Minimize time, distance, and cost while meeting all constraints.

- Key Technology: Algorithms solving the Vehicle Routing Problem (VRP).

- Dynamic Elements: Real-time traffic data and last-minute order adjustments.

- AI Integration: Using historical data to improve ETA accuracy and predict demand.

- Primary Benefit: Higher drop density and significantly lower operational overhead.

- Sustainability: Lower CO2 emissions through reduced mileage and idling.

- Success Factor: Clean data and driver buy-in are required for implementation.

Common Questions About Delivery Route Optimization

How is optimization different from Google Maps?

The answer is scale and constraints. Google Maps finds the best way for one person to get from point A to point B. Optimization finds the best way for 20 drivers to visit 500 points while considering vehicle size, customer hours, and driver shifts. Google Maps is for navigation, while optimization is for fleet management.

Do small fleets really need this software?

Yes, and here is why. Even with just two or three vehicles, the number of possible routes is in the thousands. Manual planning is time-consuming and prone to human bias. Small businesses often benefit most from optimization because they have less room for error in their margins.

Can route optimization handle refrigerated or specialized goods?

Absolutely. You can set specific constraints for vehicle types, such as “refrigerated only” for certain orders. The software will ensure that temperature-sensitive items are only assigned to the correct trucks and prioritized to minimize time in transit.

How much can I expect to save?

While every business is different, most operations see a 10 to 20 percent reduction in mileage and fuel costs within the first few months. This often pays for the software subscription many times over. The direct answer is that the ROI is usually very fast.

When it comes to delivery route optimization, the details matter. It is a powerful lever that can transform your logistics from a cost center into a competitive advantage. By embracing dynamic routing, leveraging AI, and focusing on route efficiency, you are setting your business up for long-term success. The technology is here, and it is more accessible than ever. Your best move is to start looking at your data today and see where those hidden efficiencies are waiting to be found.