Safety Stock Calculation: Methods and Formulas Explained

Looking for the exact breakdown of a safety stock calculation? You have come to the right place. While general guides cover the basics, you need the specific details that actually help you maintain service levels without overstocking your warehouse. We are going to get straight into what works, what does not, and exactly what you should do. For a broader look at how these buffers fit into your overall operation, you can explore our guide on the best inventory management methods. Let us get specific.

If you are reading this, you probably already know that running out of product is expensive. You are likely searching for a more precise way to manage your safety inventory than just “guessing” a number. We have seen this question come up constantly, so let us settle it. This is the detailed breakdown you have been searching for, designed to help you balance customer satisfaction with your actual working capital.

The Core Logic of Safety Stock

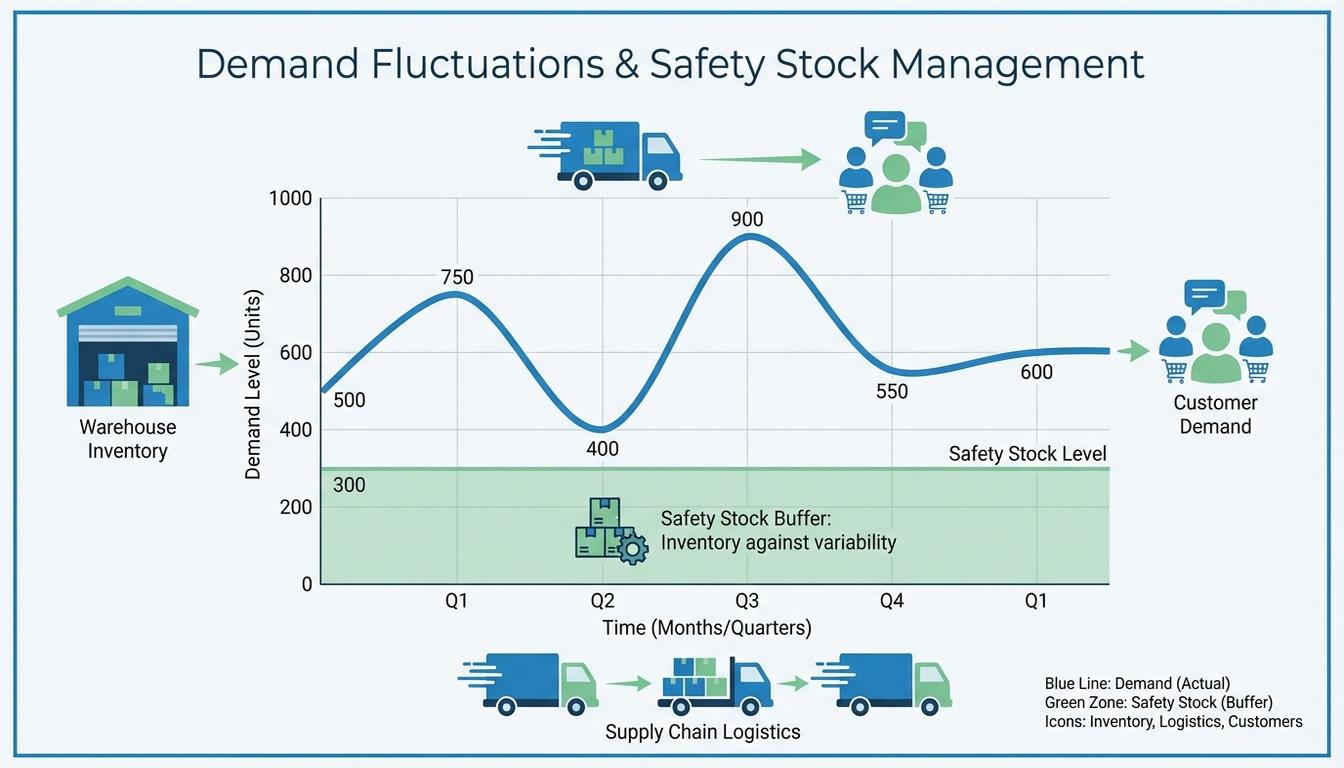

At its heart, safety stock is your demand variability buffer. It exists because the real world is messy. Suppliers are late. Customers buy more than they promised. Forecasts are almost always wrong. We hold safety stock specifically to cover the deviations from the average demand, not the average demand itself. That is the job of cycle stock.

The goal is simple. We want to achieve a target service level at the minimum total cost. If you hold too much safety inventory, you tie up cash in products that might become obsolete. If you hold too little, you lose sales and frustrate customers. The key is to find that mathematical “sweet spot” where your stock buffer calculation protects you against most likely scenarios without bloating your balance sheet.

Your best move here is to stop treating safety stock as a static number. In practice, this means you should view it as a strategic lever. When lead times grow or demand becomes volatile, your safety stock levels must move in response. Let us look at this closely and see how to quantify that movement.

Basic Formulas for Quick Estimates

Sometimes you need a fast answer. You might not have the historical data required for complex statistics. Or perhaps you are managing low-value items where a “good enough” number is fine. In these cases, we use rule-based safety stock formulas.

The Safety Days Method

This is the most intuitive approach. You simply decide how many days of “cushion” you want. If your average daily sales are 50 units and you want a 4 day buffer, you hold 200 units of safety stock. It is straightforward. It works well for stable environments where demand rarely spikes.

The practical takeaway is that this method relies entirely on your intuition. It does not actually account for how much your demand fluctuates. If you have a highly volatile product, 4 days of stock might not be enough. If demand is perfectly flat, 4 days is far too much. Use this only when data maturity is low.

The Max-Average Method

This is a widely taught rule. It looks at your worst-case scenario versus your typical scenario. The formula is:

(Maximum Daily Usage x Maximum Lead Time) – (Average Daily Usage x Average Lead Time)

Here is what that actually looks like. Imagine you usually sell 100 units a day with a 7 day lead time. In the worst case, you sell 150 units a day and the supplier takes 10 days. Your calculation would be (150 x 10) – (100 x 7), which equals 800 units. The action item here is simple. Use this formula if you have clear visibility into your worst-case delays, but be careful. It is sensitive to outliers. One massive spike can inflate your buffer for the rest of the year.

Statistical Calculations for Precision

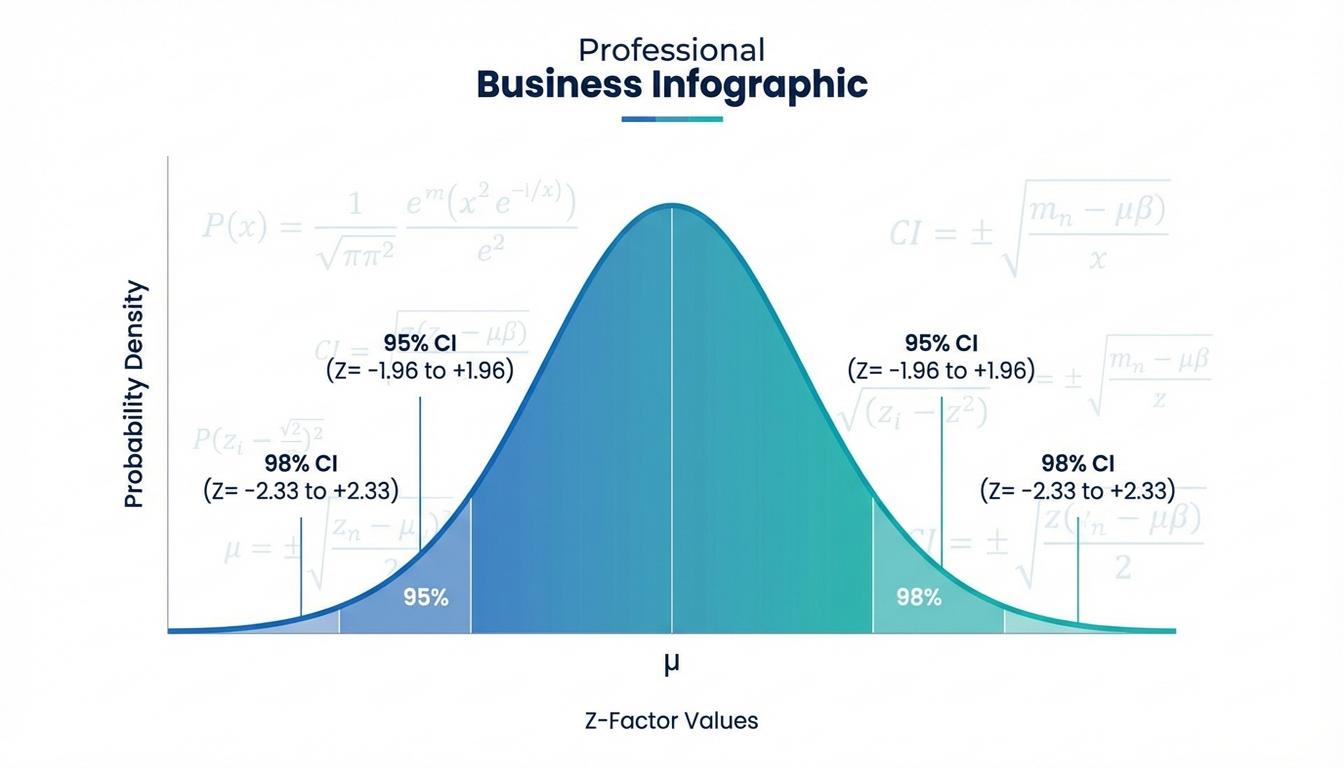

This is where we get into the details that change everything. Statistical safety stock calculation uses probability to give you a specific service level, such as 95% or 98%. Most professional supply chains use these methods because they are more economical. They ensure you are only holding as much stock as the math says you actually need.

The Normal Distribution and the Z-Factor

To use these formulas, we need to understand the Z-factor. Think of this as your “confidence score.” If you want to be 95% sure you won’t stock out, you use a Z-factor of 1.65. If you want 98% certainty, you use 2.05. According to inventory analysis from MIT, these statistical approaches are the most effective way to prevent stockouts while managing capital.

The Standard Formula (Uncertain Demand, Constant Lead Time)

If your supplier is perfectly reliable but your customers are unpredictable, use this formula:

Safety Stock = Z x Standard Deviation of Demand x Square Root of Lead Time

Let us get specific here. If your daily demand has a standard deviation of 10 units, your lead time is 9 days, and you want a 95% service level (Z = 1.65), the math is 1.65 x 10 x 3. That equals 49.5 units. You would round up to 50. This formula is the workhorse of inventory management. It is exactly what you need to know for most retail or e-commerce situations.

Calculating Both Demand and Lead Time Uncertainty

What happens when the supplier is just as unpredictable as the customer? This is the specific situation where the basic formulas fail. If your lead times fluctuate, you need a formula that captures both sources of variability. This is one of those areas where getting it right makes a real difference in your bottom line.

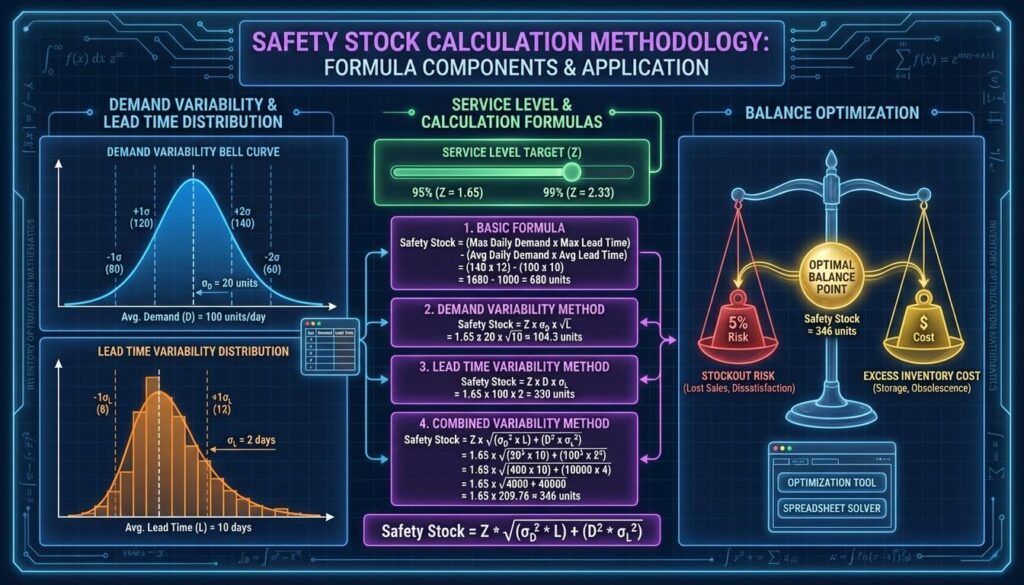

The formula looks intimidating, but the logic is sound. We calculate the variance of demand and the variance of lead time, then combine them. Here is the step-by-step breakdown:

- Calculate the average demand (D) and average lead time (L).

- Calculate the standard deviation of demand (σD) and standard deviation of lead time (σL).

- Use the formula: Z x Square Root of [(L x σD^2) + (D x σL^2)].

The first part of the formula covers demand spikes. The second part covers supplier delays. By combining them, you create a robust buffer stock that protects you on both fronts. This is the gold standard for global supply chains where shipping delays are common. If you are dealing with overseas manufacturers, this is your best move.

Safety Stock in Periodic Review Systems

Not every business checks inventory continuously. If you only place orders every Monday, or once a month, you are using a periodic review system. In this case, your safety stock must cover a longer period. Specifically, it must protect you during the review period plus the lead time.

The formula changes slightly to: Z x σD x Square Root of (Review Period + Lead Time). Because the window of uncertainty is wider, your safety stock will naturally be higher. Ready for the specifics? If you review every 7 days and the lead time is 7 days, you need enough buffer to survive 14 days of unexpected demand spikes. This is why continuous review systems are often more inventory-efficient, though they require more advanced software to track stock levels in real-time.

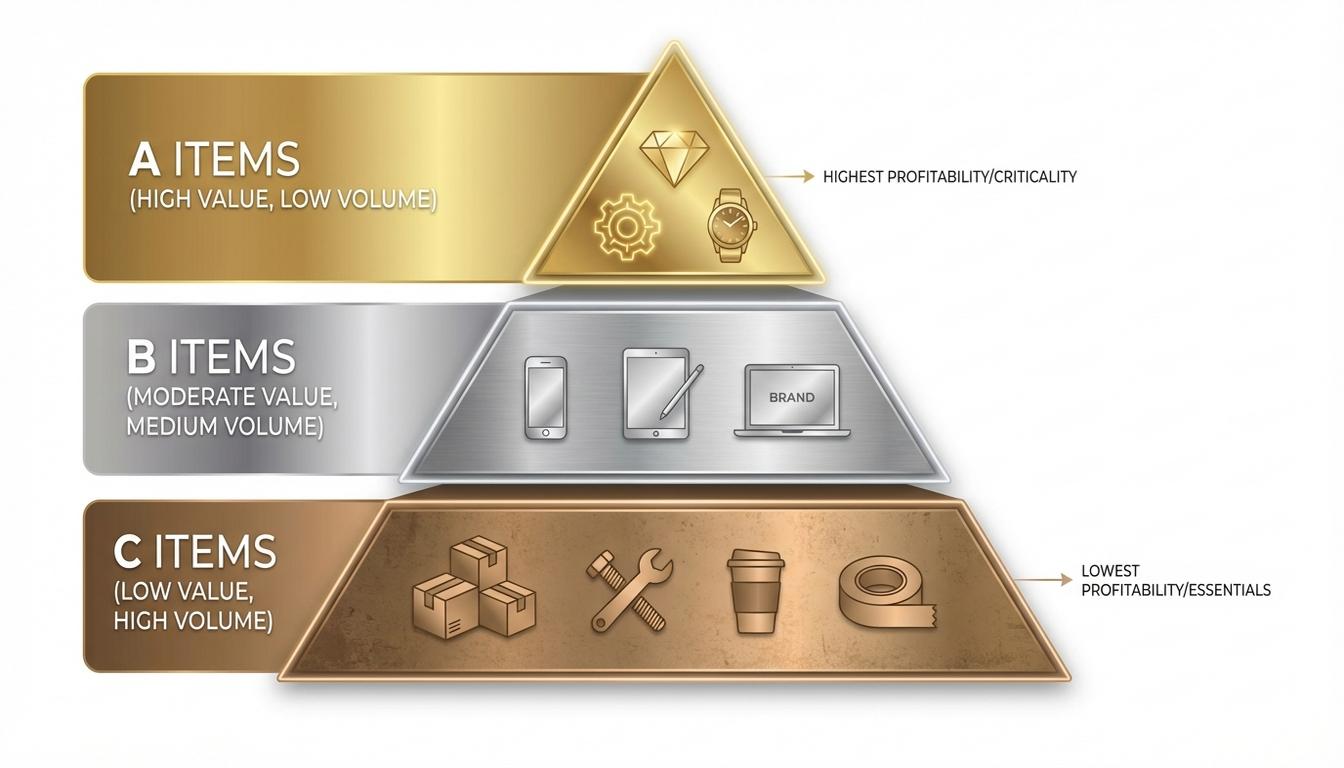

Strategic Implementation and ABC Analysis

You should not apply the same safety stock calculation to every item in your warehouse. That is a mistake that leads to “lazy” inventory. Some items are high-value and critical. Others are slow-moving accessories. This is where abc inventory classification becomes your most powerful tool.

Your “A” items, which generate most of your revenue, deserve higher service levels (98% or higher). They need the full statistical treatment. “C” items are often the long tail. For these, you can use the simpler Max-Average method or even zero safety stock if the item is easily replaceable. Segmenting your approach allows you to focus your cash where it generates the most protection.

Once you have determined your safety stock levels, you can integrate them into your reorder point. The reorder point is simply the average demand during lead time plus your safety stock. When your inventory hits this number, you place a new order. To find the most cost-effective amount to order at that time, you might want to look into our economic order quantity guide. Combining EOQ with statistical safety stock creates a highly optimized replenishment cycle.

Quick Reference: Safety Stock Formulas at a Glance

- Safety Days: (Average Daily Demand) x (Desired Days of Buffer). Best for low-data maturity.

- Max-Average: (Max Usage x Max Lead Time) – (Avg Usage x Avg Lead Time). Best for visible worst-case scenarios.

- Statistical (Demand Only): Z x σD x √Lead Time. Best for reliable suppliers and variable demand.

- Statistical (Combined): Z x √[(L x σD^2) + (D x σL^2)]. Best for high-uncertainty global supply chains.

- Periodic Review: Z x σD x √(Review Period + Lead Time). Best for fixed-interval ordering schedules.

Your next step is to gather your historical data. You need at least 6 to 12 months of daily sales and supplier delivery dates to calculate accurate standard deviations. Without good data, the most advanced formula in the world is just a guess. Research from the Association for Supply Chain Management suggests that data-driven methods consistently outperform “gut feel” by 15% to 30% in inventory cost reduction.

Common Questions About Safety Stock Calculation

How often should I recalculate my safety stock?

The answer is that it depends on your volatility. For most businesses, a quarterly review is sufficient. However, if you are experiencing rapid growth or supply chain disruptions, a monthly recalculation is better. Dynamic safety stock systems can even automate this daily.

Can safety stock be zero?

Yes, and for some items, it should be. If you have a product with perfectly predictable demand and a local supplier who delivers in hours, you don’t need a buffer. Similarly, obsolete items or custom made-to-order products should have zero safety stock to avoid waste.

What is a good service level for safety stock?

There is no one-size-fits-all answer. Most retail businesses aim for 95%. Critical industries like medical supplies or aerospace might aim for 99.9%. The real question is how much you are willing to pay for that extra percentage, as the cost of inventory rises exponentially as you approach 100%.

Why does lead time variability matter so much?

Lead time variability is often more dangerous than demand variability. If a customer buys 10 extra units, it is a minor spike. If a supplier is two weeks late on a shipment of 1,000 units, your entire operation stops. This is why the combined statistical formula is so vital for global operations.

Let us get to the bottom line. Safety stock is not a “set it and forget it” number. It is a living part of your operation. When it comes to safety stock calculation, the details matter. By moving away from simple percentages and toward statistical variability, you protect your cash flow and your customers simultaneously. Start with your “A” items, run the numbers for 95% service levels, and adjust based on real-world performance. That is the most direct path to a resilient supply chain.