Cold Chain Temperature Monitoring: Systems and Best Practices

Are you looking for the exact breakdown of how cold chain temperature monitoring works in a modern supply chain? You have come to the right place. While general guides cover the basics of logistics, you need the specific details that actually help you maintain product integrity and stay compliant with strict regulations. We are going to get straight into what works, what does not, and exactly what you should do to protect your temperature sensitive shipments. Let us get specific.

Most logistics professionals understand that keeping things cold is important. You likely already know the basic temperature ranges, such as 2 to 8 degrees Celsius for refrigerated goods or -20 degrees Celsius for frozen products. However, the difference between a successful operation and a total loss often comes down to the granularity of your data. This is the detailed breakdown you have been searching for to move beyond basic cooling and into true environmental visibility. We are moving from “is the fridge on?” to “what is the exact thermal history of this specific pallet?”

What Cold Chain Temperature Monitoring Actually Accomplishes

Cold chain temperature monitoring is the continuous measurement, recording, and control of temperatures for sensitive products like pharmaceuticals, biologics, and fresh food. It is not just about a thermometer on a wall. It is a set of devices, processes, and systems designed to ensure the chain remains unbroken from the point of production to the point of use. When we talk about monitoring, we are talking about creating a tamper evident record of every minute a product spends in transit or storage.

The core goals are simple but difficult to execute. We want to maintain product safety, prevent spoilage, and provide the documentation required by auditors. If a vaccine loses potency because it sat on a hot tarmac for twenty minutes, you cannot see that damage with the naked eye. Only accurate, continuous records can prove the product is still safe for the patient. Here is what that actually looks like in practice. We use sensors to track not just the air temperature, but often humidity, light exposure, and even physical shock. These factors can all impact the shelf life and safety of high value goods.

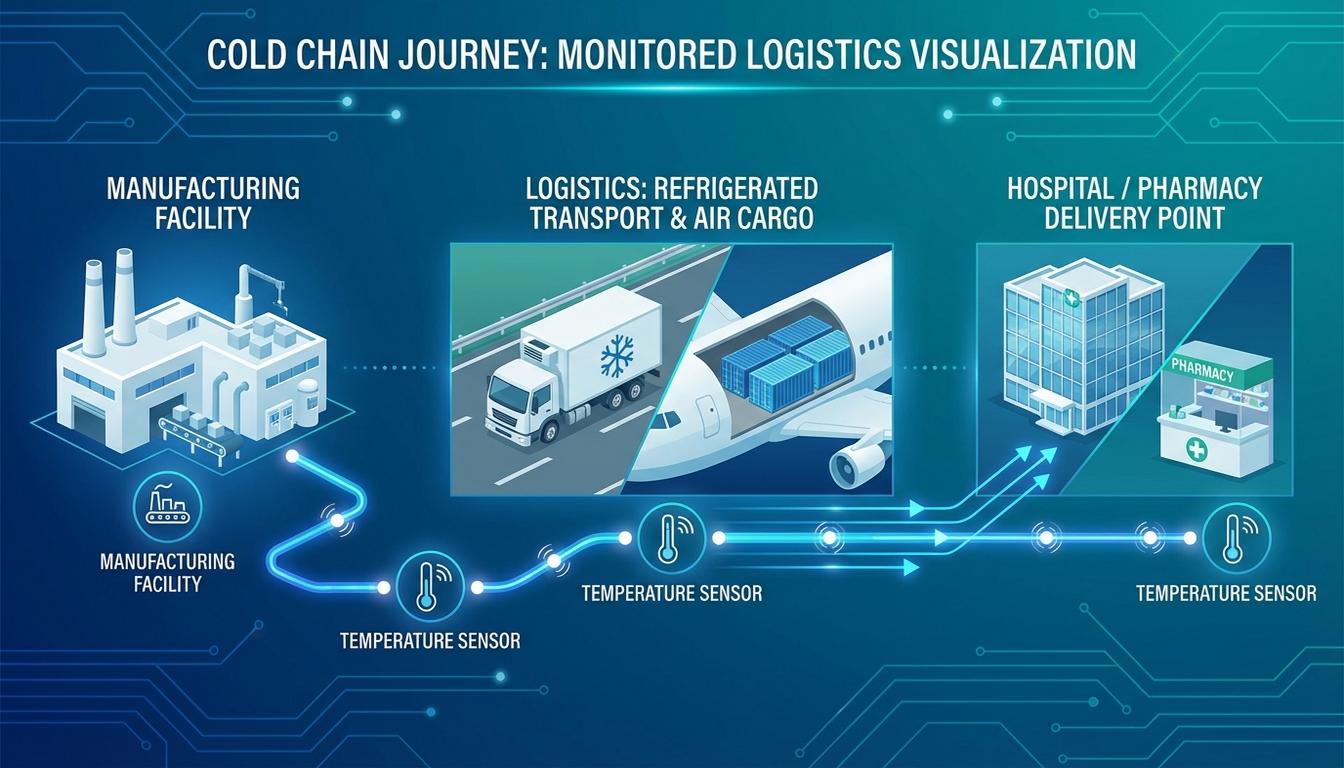

The scope of this monitoring is massive. It covers everything from the manufacturing plant and the warehouse to the various transport modes like trucks, air freight, and ocean containers. The real question is how you bridge the gaps between these handoff points. Each time a product moves from a truck to a loading dock, the risk of a temperature excursion increases. Monitoring systems act as the safety net that catches these deviations before they become disasters.

The practical takeaway is this. Monitoring is your insurance policy against the invisible risks of the supply chain. Your next step is to evaluate which of the following monitoring methods fits your specific risk profile and budget.

Comparing Data Loggers and Real Time Monitoring

When it comes to cold chain temperature monitoring, you generally have two main paths to choose from. Let us look at this closely. You can either use traditional temperature data loggers or invest in real time monitoring systems. Both have their place, but they serve very different operational needs. The choice you make determines whether you are reacting to problems after they happen or preventing them as they occur.

Traditional Temperature Data Loggers

These are standalone electronic devices that measure and store temperature data at defined intervals. They are incredibly common because they are simple and cost effective. You place a logger in a shipment, and it records the data for the duration of the trip. Once the shipment arrives, someone has to physically retrieve the device and download the data via USB or Bluetooth to see if any excursions occurred.

- Pros: Low cost, high reliability, and no need for constant cellular or Wi-Fi connectivity.

- Cons: You only find out about a problem after the shipment has already arrived. This is retrospective monitoring.

- Best Use Case: Routine pharmaceutical shipments or food exports where the risk is manageable and the cost of real time hardware is not justified.

Real Time Temperature Monitoring

This is where the industry is moving. Real time systems use IoT temperature sensors that transmit data continuously via cellular, Wi-Fi, or satellite networks. If the temperature drifts outside of the allowed range, the system sends an immediate alert via SMS or email to your team. This allows for immediate intervention, such as calling a driver to check a reefer setting or rerouting a truck to a nearby cold storage facility. In many cases, these sensors are integrated into the transport equipment itself. To understand more about the vehicles used in these scenarios, you can read our guide on refrigerated truck types.

- Pros: Immediate visibility, proactive risk management, and integrated GPS tracking.

- Cons: Higher hardware costs, ongoing subscription fees, and dependence on network coverage.

- Best Use Case: High value biologics, clinical trial materials, and vaccines where even a single excursion results in a total loss.

So which approach works best? The answer depends on your tolerance for risk. If you are moving millions of dollars in life saving medicine, the cost of a real time system is a drop in the bucket compared to the cost of a lost load. If you are moving shelf stable produce that is just being chilled for quality, data loggers are usually sufficient.

IoT Temperature Sensors and Wireless Networks

Let us get into the details of the technology powering modern systems. IoT temperature sensors are the backbone of what we call cold chain visibility. These devices are much more than just thermometers. They are networked nodes that form a smart ecosystem. By using technologies like Bluetooth Low Energy (BLE), LoRaWAN, and cellular IoT, we can now track conditions at a level of detail that was impossible a decade ago.

One of the most effective setups for large facilities involves a wireless sensor network. In this scenario, dozens or even hundreds of small BLE sensors are placed throughout a warehouse or distribution center. These sensors talk to central gateways, which then push the data to a cloud platform. This eliminates the need for manual temperature checks. Instead of a staff member walking around with a clipboard, you have a live dashboard that updates every few minutes. This is one of those areas where getting it right makes a real difference in labor costs and accuracy.

RFID temperature sensors also play a specialized role here. These are often used for automated inventory tracking. When a pallet passes through an RFID portal at a loading dock, the system can automatically read the temperature history stored on the tag. It is a seamless way to integrate quality control into the flow of goods. Here is a quick reality check. While these technologies are powerful, they require a robust IT infrastructure and clear protocols for how to handle the massive amount of data they generate.

Your best move here is to start with a pilot program. Don’t try to outfit your entire global fleet at once. Pick a high risk route, deploy IoT sensors, and see how the real time data changes your decision making. The action item here is to identify your most vulnerable “blind spots” in the supply chain and target those first with wireless solutions.

Hardware Placement and the Science of Mapping

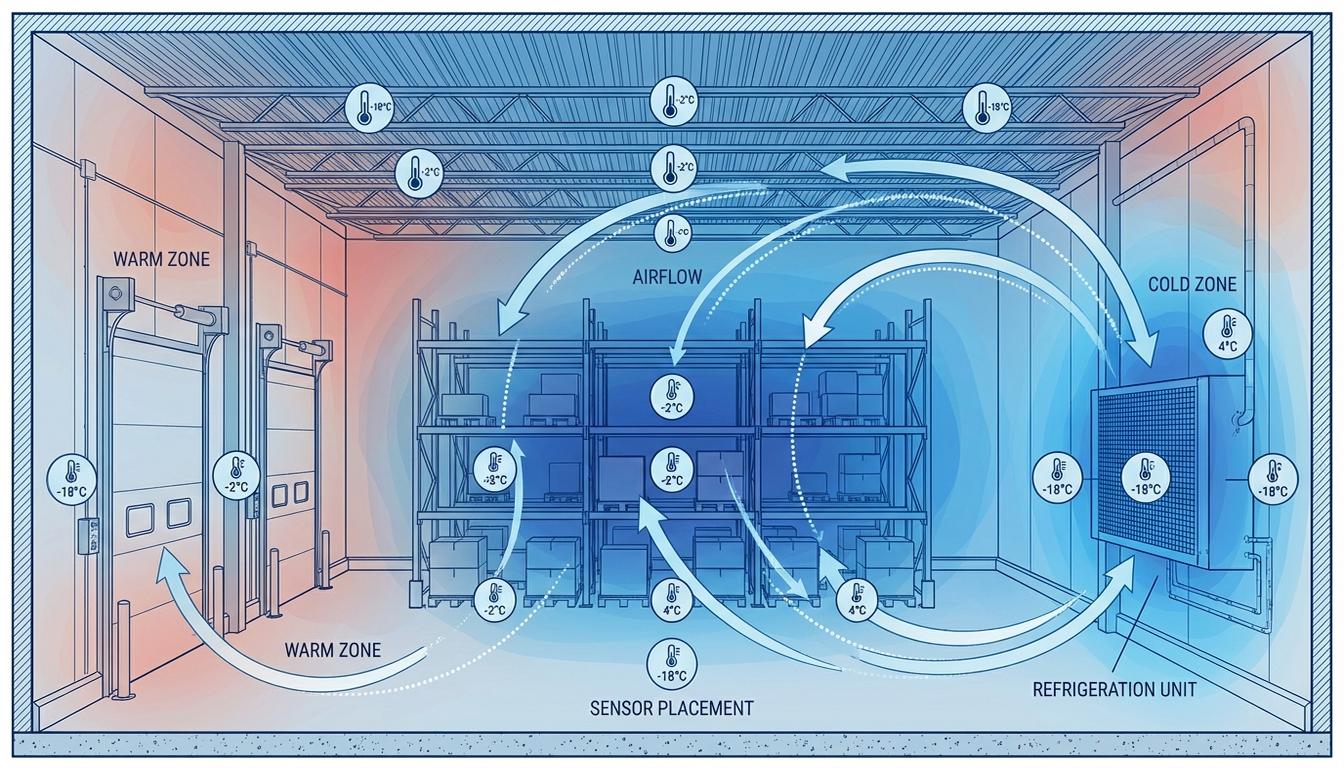

This is the part you actually came here for. Even the most expensive sensor is useless if you put it in the wrong place. We see this mistake constantly. People put a single sensor near the door of a cold room and assume the whole room is fine. In reality, temperatures vary significantly based on airflow, proximity to cooling units, and how the inventory is stacked. This is where we need to distinguish between cold chain monitoring and temperature mapping.

Temperature mapping is a validation activity. It is a study you perform over a set period, usually several days, to identify the “hot spots” and “cold spots” in a specific space. According to the World Health Organization (WHO), mapping should be done for any new storage area and repeated periodically. You can find their technical recommendations in the WHO cold chain management resources. Once you have identified these spots, you place your permanent monitoring sensors in the areas most likely to experience a deviation. Usually, this means the warmest spot (near a door or high on a shelf) and the coldest spot (directly in front of the cooling fan).

When it comes to warehouses, the physical layout dictates your sensor strategy. Proper airflow is everything. If you are currently designing or optimizing a facility, understanding the interaction between storage racks and cooling is vital. For more on this, check out our insights on cold storage warehouse design to see how layout impacts thermal stability.

Practical rules for sensor placement include:

- Place sensors at different heights to account for heat rising.

- Keep sensors away from direct contact with walls, as they can act as heat sinks or cold bridges.

- Ensure sensors are placed within the “product zone” rather than just in empty air.

- In trailers, place sensors near the rear doors where heat ingress is most likely.

In practice, this means you should always lead with a mapping study before you finalize your monitoring plan. The direct answer is that monitoring tells you what is happening today, but mapping tells you where you need to look.

Software Platforms and Predictive Analytics

Collecting data is only half the battle. The other half is what you do with it. Modern cold chain temperature monitoring relies on cloud based platforms that centralize data from every sensor in your network. These platforms provide the “single source of truth” that managers need to oversee complex operations. But we are seeing a shift from simple dashboards to active analytics.

Advanced platforms now use AI driven predictive analytics. Instead of just telling you that a refrigerator is currently at 9 degrees, the system can analyze the temperature trend and predict that the unit will fail within the next four hours. This gives your maintenance team a head start. It turns a potential disaster into a routine repair. These systems can also identify systemic issues, such as a specific delivery route that consistently has more excursions than others due to traffic delays or poor driver habits.

Another critical feature of software is compliance documentation. For industries like pharmaceuticals, you need to provide tamper evident reports that prove the product stayed within spec. Manual spreadsheets are no longer enough. The software should automatically generate these reports, including any “Corrective and Preventive Action” (CAPA) logs that explain what was done when an excursion occurred. This is the detail that changes everything during a regulatory audit.

Your next step is to look for a platform that offers “exception based reporting.” You do not want to spend your day looking at thousands of “normal” readings. You want a system that only flags the anomalies so you can focus your attention where it is actually needed.

Regulatory Context and Compliance Standards

If you are in the food or pharmaceutical business, you aren’t just monitoring for quality. You are monitoring because the law requires it. Regulations from the FDA and European Medicines Agency (EMA) are very clear about the need for documented temperature control. For example, the FDA’s Food Safety Modernization Act (FSMA) places heavy emphasis on the transportation of perishables. You can review the specifics of these rules on the FDA official FSMA page.

In the pharmaceutical world, we follow Good Distribution Practice (GDP). These guidelines require a fully validated cold chain. This means you must prove that your equipment is capable of maintaining the required temperatures, your staff is trained to handle the products, and your monitoring system is accurate and reliable. Auditors will look for your calibration records for every sensor you use. If you cannot prove your sensors were calibrated recently, your data is essentially worthless in their eyes.

Key regulatory expectations include:

- Continuous records for the entire duration of storage and transit.

- Validated software that complies with 21 CFR Part 11 (for electronic signatures and records).

- Clear Standard Operating Procedures (SOPs) for responding to alarms.

- Regular calibration of all thermal monitoring hardware.

When it comes to global logistics, the complexity grows. You may be dealing with different regulations in every country your product touches. This is why having a standardized, global monitoring platform is so important. It ensures that everyone in your supply chain is playing by the same rules and using the same data standards.

Quick Reference: Cold Chain Monitoring at a Glance

- Core Technology: Combination of hardware sensors (Data loggers, IoT, RFID) and cloud software.

- Primary Goal: Protecting product safety and ensuring regulatory compliance through continuous records.

- Key Ranges: Refrigerated (2–8°C), Frozen (-20°C), Ultra-cold (-80°C).

- Real-Time Benefit: Allows for immediate intervention and proactive risk management.

- Validation: Temperature mapping is required to find hot and cold spots before placing sensors.

- Compliance: Must meet FDA, WHO, and GDP standards for documented proof of control.

- Future Trend: AI and predictive analytics to anticipate equipment failure before it happens.

Common Questions About Cold Chain Temperature Monitoring

Is real time monitoring always better than using data loggers?

The answer is no, not always. While real time systems offer better visibility, they are more expensive and require cellular coverage. For low risk shipments or routes with poor connectivity, a high quality data logger is often a more reliable and cost effective choice. It really depends on whether you have the operational capacity to act on real time alerts.

How often should sensors be calibrated?

Most industry standards, including GDP, recommend annual calibration for all temperature monitoring devices. However, if you are working with ultra cold shipments or highly sensitive biologics, you might choose to calibrate every six months to ensure maximum accuracy. Always follow the manufacturer’s recommendations and your own internal quality standards.

What is the most common cause of temperature excursions?

Surprisingly, it is often human error rather than equipment failure. Common issues include leaving loading dock doors open too long, failing to pre-condition insulated shippers, or drivers turning off reefer units to save fuel. This is why staff training and clear SOPs are just as important as the sensors themselves.

Can I use Wi-Fi sensors in a refrigerated truck?

Generally, Wi-Fi is not the best choice for a moving vehicle because it loses connection as soon as the truck leaves the warehouse. For transit, cellular IoT or satellite based systems are the standard. Wi-Fi sensors are excellent for fixed locations like warehouses or hospital pharmacies where a stable network is already in place.

Moving Forward with Your Monitoring Strategy

We have covered a lot of ground, from the hardware specifics of BLE sensors to the regulatory requirements of GDP. The most important thing to remember is that cold chain temperature monitoring is a process, not just a product. It requires the right technology, but it also requires the right people and protocols to make that technology effective. You cannot just “set it and forget it.”

The practical takeaway is that visibility is your greatest tool for efficiency. When you know exactly where your products are and what conditions they are facing, you can make better decisions that save money and, more importantly, save lives. If you are just starting to build out your thermal monitoring program, your first step should be a thorough risk assessment of your current lanes. Look for the gaps where data is missing and fill them with the appropriate level of technology.

For a complete overview of how these monitoring systems fit into the bigger picture of moving goods safely, check out our main guide on cold chain logistics. It will help you connect the dots between monitoring, transport, and storage strategy. Your next action is simple. Review your last three months of temperature data and look for patterns. If you see recurring issues in the same locations, it is time to perform a new mapping study and upgrade your sensors. Stay focused on the details, and your cold chain will remain strong.