Cold Storage Warehouse Design: Key Considerations

Looking for the exact breakdown of how to handle cold storage warehouse design? You have come to the right place. While general guides cover the basics of warehousing, you need the specific details that actually help you maintain a precise environment for perishables. We are going to get straight into what works, what does not, and exactly what you should do to ensure your facility remains efficient and compliant. Let us get specific.

If you are reading this, you probably already know the basics of storage, but you are looking for the detailed breakdown of thermal management and specialized engineering. This is one of those areas where getting it right makes a real difference. A single degree of temperature deviation can lead to massive inventory loss. We have seen this question come up constantly, so let us settle the best practices for building and laying out these complex environments. For a complete overview of the broader industry movement, check out our main cold chain logistics guide for additional context.

The Foundations of Site Selection and Planning

When it comes to cold storage warehouse design, the first step happens before you ever break ground. You are looking for a site that supports massive power needs and offers enough room for specialized dock operations. The real question is, does your site choice help or hinder your refrigeration efficiency? Most people look at logistics costs first, but in the cold world, utility access is just as important.

Your site must accommodate the high electricity demands of industrial-scale cooling. We recommend looking for industrial zoning that provides redundant power grids. If the grid fails, your inventory is on a timer. Site orientation is also a factor. If you can orient the building to minimize direct sun exposure on the loading docks, you reduce the heat load on the refrigeration system from the very start. This is the detail that changes everything for long-term operational costs.

The practical takeaway is to prioritize proximity to transportation networks. You want to minimize the time goods spend in transit between the facility and a refrigerated truck types guide to ensure the thermal bridge remains as short as possible. Efficient distribution is the goal, but it should not come at the expense of energy stability.

- Utility Access: High-voltage power and consistent water supply for cooling towers.

- Building Orientation: Minimize southern sun exposure to reduce cooling loads.

- Future Expansion: Cold storage is expensive to build, so ensure the site allows for modular additions.

- Environmental Compliance: Check for local regulations regarding refrigerants and wastewater.

Mastering the Building Envelope and Insulation

The building envelope is the single most critical component of an insulated warehouse. Here is the specific answer for anyone wondering how to keep the cold in and the heat out: it is all about continuous thermal barriers. Any gap in your insulation is a thermal bridge that invites frost, condensation, and mold. This is where most projects fail by trying to cut costs on installation quality.

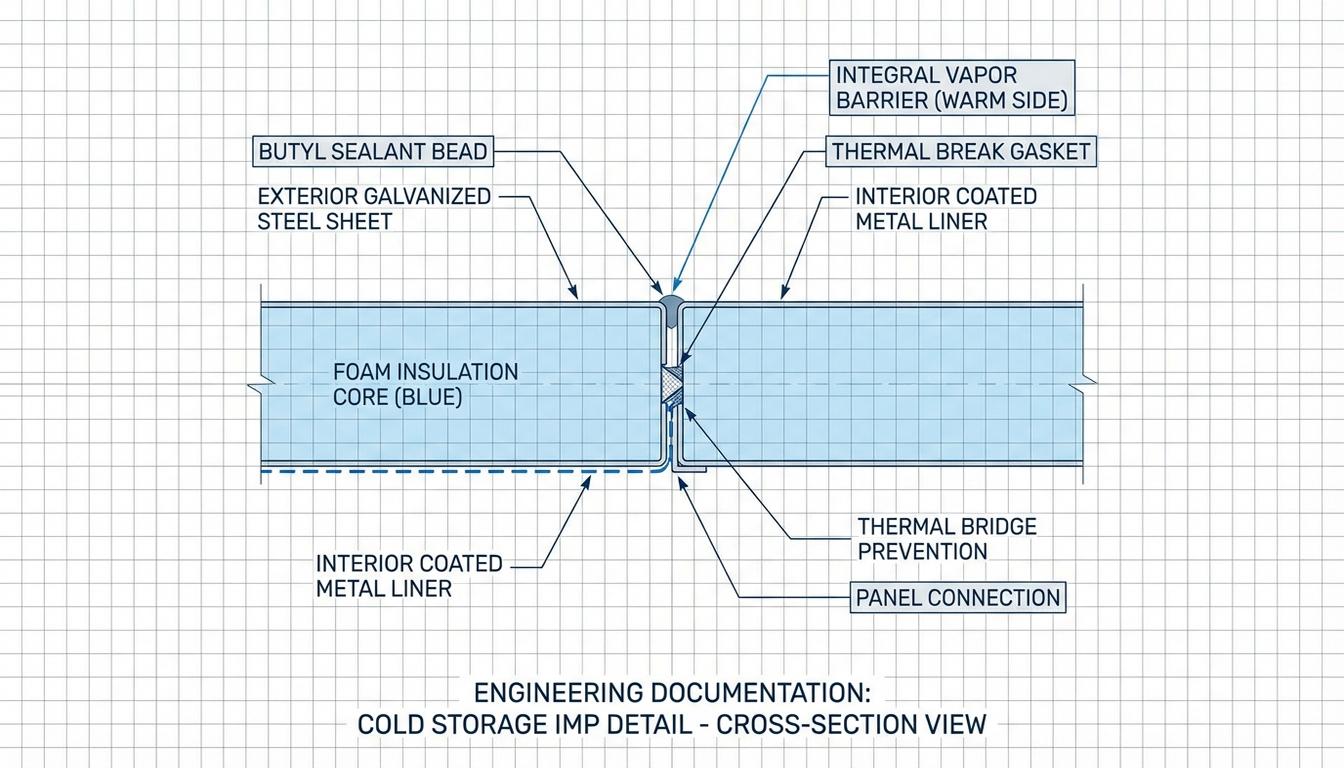

We suggest using high-quality Insulated Metal Panels (IMPs). These panels serve as the wall, the insulation, and the vapor barrier all in one. They provide a continuous thermal seal when installed correctly. Let us look at this closely. The panels must be interlocked perfectly with specialized sealants at every joint. If air can move, moisture will follow, and once ice starts forming inside a wall, the structural integrity is at risk.

Do not forget the floor. Many designers overlook the fact that the ground can freeze and heave under a freezer warehouse. Your best move here is to install a sub-floor heating system, often using glycol-filled pipes or electric heat mats, to prevent the soil from freezing. On top of that, you need high-density floor insulation and a heavy-duty vapor barrier to keep moisture from migrating upward. According to the Global Cold Chain Alliance, thermal integrity is the leading factor in energy cost management for modern facilities.

Critical Insulation Components

- Insulated Metal Panels (IMPs): Provide high R-values and quick installation.

- Vapor Barriers: Essential for preventing condensation within the wall assembly.

- Roof Insulation: Needs to be thicker than standard warehouses to combat solar gain.

- Sub-floor Heating: Prevents ground heaving in freezer environments.

Optimizing the Refrigerated Warehouse Layout

Designing a refrigerated warehouse layout requires a balance between storage density and airflow. If you pack the room too tightly, the cold air cannot reach the center of the pallets. If you leave too much open space, you are paying to cool empty air. So which approach works best? The answer is a layout designed for multi-temperature zoning.

Here is what that actually looks like in practice. You divide the facility into distinct zones: frozen (below -18°C), chilled (0°C to 4°C), and ambient. Use modular, insulated partitions that can be moved as your inventory needs change. This flexibility allows you to expand your freezer space during peak seasons without rebuilding the entire facility. This is exactly what you need to know if you handle a variety of product types like produce and pharmaceuticals simultaneously.

Traffic flow is another area where efficiency is won or lost. You want to minimize the time doors are open. Use high-speed doors and airlocks at every entrance. The layout should guide forklifts through a staging area or “anteroom” that is kept at an intermediate temperature. This acts as a buffer zone, preventing a direct rush of warm, humid air into the freezer. To manage this effectively, many operators integrate cold-chain temperature monitoring systems that alert staff if a door is left open too long or if a zone begins to drift.

The practical takeaway is to keep your highest-volume items closest to the loading docks but within a temperature-controlled staging zone. This reduces travel time and keeps the deep-freeze doors closed as much as possible.

Choosing the Right Refrigeration System

When it comes to cold room design, the heart of the operation is the refrigeration plant. You have a choice between centralized and decentralized systems. The short version is that centralized systems (using a large central ammonia plant) are often more energy-efficient for massive facilities, while decentralized units (multiple smaller units) offer better redundancy and easier maintenance for smaller operations. Let us get into the details.

Ammonia is the gold standard for large industrial cold storage because of its incredible efficiency. However, it requires strict safety protocols and specialized training for staff. For smaller footprints or urban areas, CO2 systems are becoming increasingly popular. CO2 is non-toxic and has a very low global warming potential compared to synthetic refrigerants. Ready for the specifics? Your choice of refrigerant will dictate your insurance costs and regulatory compliance requirements.

Smart monitoring is no longer optional. Modern systems use real-time controls to adjust compressor speeds based on current demand. They can detect a refrigerant leak or a failing motor long before it becomes a catastrophe. In practice, this means you should invest in a system that offers remote access and predictive maintenance alerts. This is the detail that changes everything when you are managing a facility 24/7.

Common Refrigerants in Cold Storage

- Ammonia (R-717): Highly efficient, cost-effective for large scale, but requires safety management.

- Carbon Dioxide (R-744): Environmentally friendly, excellent for low temperatures, but operates at high pressure.

- Synthetic Refrigerants (HFOs/HFCs): Used in smaller systems, though increasingly regulated due to environmental impact.

Automation and Space Utilization

Building “up” instead of “out” is the most effective way to manage costs in cold storage warehouse design. Why? Because the most expensive part of your facility is the roof and the floor. By increasing the height of your building, you minimize the footprint that needs to be insulated and cooled. This is where automation, specifically Automated Storage and Retrieval Systems (AS/RS), becomes a game-changer.

An automated freezer warehouse can be built significantly taller than a traditional one—sometimes over 100 feet. Automation thrives in the cold because it eliminates the need for human-centric design elements like wide aisles for forklifts or high-intensity lighting. Robots do not mind the dark, and they do not need to take “warm-up” breaks. This can reduce your facility’s square footage by up to one-third while maintaining the same storage capacity.

Now for the part you actually came here for: the cost-benefit reality check. Automation is a massive upfront investment. However, when you factor in the reduced energy costs (smaller footprint to cool) and the lower labor costs (fewer people working in harsh conditions), the ROI often makes sense for long-term operations. If you are building a new temperature controlled facility from scratch, you should at least design the slab and structure to support future automation, even if you do not install it on day one.

Your next step is to evaluate your product turnover. If you have high-volume, uniform pallets, automation is a perfect fit. If you have highly variable, small-order picking, a semi-automated system with high-density racking might be a better move.

Quick Reference: Cold Storage Design at a Glance

- Insulation: Use R-32 or higher for walls and R-40 to R-60 for roofs.

- Vapor Barrier: Must be on the “warm” side of the insulation to prevent internal frosting.

- Doors: High-speed, insulated roll-up doors are mandatory for energy conservation.

- Docks: Sealed dock pits prevent outdoor air from leaking in during loading.

- Flooring: Include a heated sub-slab to prevent frost heave.

- Zoning: Use adjustable partitions to manage frozen, chilled, and ambient products.

- Lighting: Use LEDs that are rated for low temperatures to reduce heat output and energy use.

Regulatory Compliance and Safety

You cannot design a cold storage facility without addressing the legal side of things. If you are storing food, you must comply with FDA HACCP principles and FSMA regulations. This means your design must allow for easy cleaning, pest control, and precise temperature logging. This is the detail that changes everything during a health inspection.

Safety is also a major design factor. Working in a freezer warehouse is physically demanding and potentially dangerous. Your design must include emergency exits that remain operable even if they frost over. Specialized fire suppression systems, like pre-action sprinklers or air-sampling smoke detectors, are necessary because standard water-filled pipes would freeze and burst. Let us get specific here: a fire in a cold storage facility is surprisingly common due to the low humidity and high volume of packaging materials. Your suppression system must be designed for the specific temperature of the room.

The action item here is simple. Consult with a fire safety engineer who specializes in cold environments early in the design phase. Do not leave this until the end of the project, or you may find yourself retrofitting expensive systems into a finished building.

Common Questions About Cold Storage Warehouse Design

What is the most energy-efficient temperature for a cold warehouse?

The direct answer is that there is no single “most efficient” temperature, as it depends entirely on the product requirements. However, the most efficient way to run a facility is to maintain the highest possible temperature that is still safe for the product. Every degree lower you go increases energy costs by roughly 2 to 3 percent.

Can I convert a dry warehouse into a cold storage facility?

Yes, but it is not as simple as adding a big AC unit. You must install a “box-in-a-box,” where you build insulated walls and a ceiling inside the existing structure. The real challenge is the floor. Without a heated sub-slab, a converted dry warehouse will eventually suffer from floor heaving, which can destroy the building’s foundation.

How do airlocks and vestibules actually save money?

The answer is moisture control. Every time a door opens, warm air enters. That air carries humidity, which turns into frost on your evaporators and ice on your floors. This makes your refrigeration system work harder to defrost. Vestibules act as a trap, catching that moisture before it enters the main storage area, which significantly lowers your OPEX.

What type of flooring is best for a freezer?

Your best move here is a monolithic concrete slab with very few joints. The concrete should be a specialized mix designed for low temperatures to prevent cracking. Below that, you need a high-compressive strength insulation layer and a heating system to prevent the ground from freezing. This setup ensures the floor remains level for forklift operations.

Getting your cold storage warehouse design right is a matter of focusing on the details that others ignore. From the glycol loops under your feet to the interlock of the IMPs above your head, every component must work together to fight the constant influx of heat and moisture. When it comes to cold storage, you are not just building a warehouse; you are building a giant, high-performance machine. Focus on the thermal envelope first, the refrigeration efficiency second, and the operational flow third. If you nail those three, you will have a facility that stands the test of time and keeps your overhead manageable. For more information on how this fits into the larger picture of moving goods, revisit our cold chain logistics guide to see how design impacts the entire supply chain. Your next move is to find a design partner who understands these specialized requirements and can help you turn these principles into a reality.