How to Build a Supply Chain Strategy That Drives Business Growth

Have you ever felt like your business is constantly firefighting? One day you are dealing with a supplier who cannot deliver. The next day, you are staring at a warehouse full of inventory that nobody wants to buy. It is exhausting. Most leaders we talk to feel this way because they are managing their operations day to day instead of following a clear supply chain strategy. The truth is that a well defined supply chain strategy is often the difference between a company that merely survives and one that dominates its market. We are going to explore why this plan matters so much and how you can build one that actually works.

We get it. The world of logistics and operations can feel like a tangled web of acronyms and complex diagrams. It is easy to feel overwhelmed when you are trying to balance costs, speed, and customer happiness all at once. You might be wondering if there is a simpler way to look at all of this. What we found is that once you strip away the jargon, a supply chain strategy is really just about making smart choices today so you do not have to panic tomorrow. It is the roadmap that tells everyone in your company which way to turn when things get messy.

In this guide, we are going to walk through everything from the basic definitions to the advanced technology that is changing the game. We will look at the different types of strategies you can choose, how to align your team, and what metrics actually move the needle. Whether you are building a strategy from scratch or trying to fix one that is broken, we are here to help you make sense of it all. Let us get into it.

What Exactly Is a Supply Chain Strategy?

When we talk about a supply chain strategy, we are talking about the high level plan that governs how your business moves materials and information. It is the big picture. Think of it as the overarching plan for how a company designs and controls the flow of goods from the very beginning to the very end. It is not just about shipping boxes or buying raw materials. It is about how those activities support your overall business goals.

The Association for Supply Chain Management defines it as an overarching plan for the planning, design, and operation of supply chain activities. You can find more details on their official definition here. In simple terms, your strategy is what determines if you are going to be the fastest in your industry, the cheapest, or the most reliable. Every decision you make, from which suppliers you hire to where you build your warehouses, should flow from this strategy.

The Core Purpose of Having a Plan

Why do we even need a formal strategy? Can we not just hire good people and let them do their jobs? Well, without a strategy, your departments will often work against each other. Your sales team might promise a two day delivery to a customer, while your logistics team is trying to save money by using the slowest shipping method. This creates friction. Here is what a solid strategy actually does for you.

- It translates your business goals into operational reality.

- It helps you make tough trade-offs, like deciding between lower costs or faster speed.

- It coordinates different functions like procurement, production, and sales under one common set of goals.

- It builds resilience so you can handle disruptions without your whole system falling apart.

Here is the bottom line. A supply chain strategy is your competitive advantage in disguise. If you can move goods more efficiently than your competitors, you can offer better prices or better service. That is how businesses grow.

Strategy vs. Management vs. Planning

This is where most people get confused. People often use the terms strategy, management, and planning as if they are the same thing. They are not. If you want to build a world class operation, you need to understand the difference between these three layers. Let us break this down into simple terms that actually make sense.

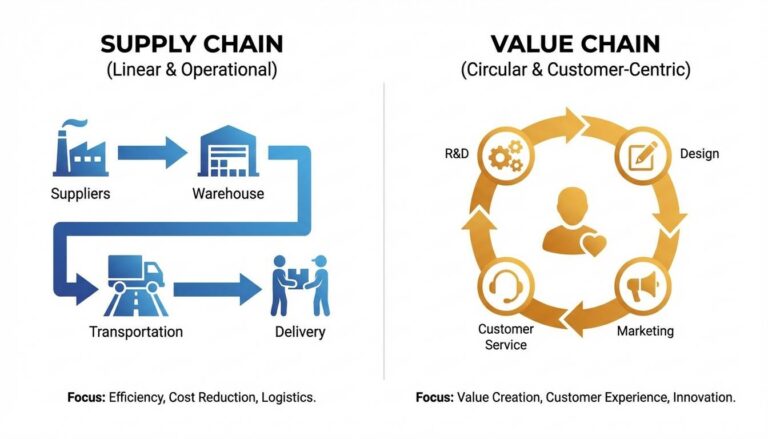

Think of your supply chain strategy as the map for a cross country road trip. It tells you your destination and the general route you will take. Supply chain management is the act of actually driving the car. It is the day to day coordination of activities like sourcing, manufacturing, and shipping. If the strategy says “we are taking the scenic route to save money,” management is the person making sure the tires are inflated and the gas tank is full. For a deeper look at how these roles connect to the bigger picture, check out our guide on supply chain vs value chain.

Where Planning Fits Into the Mix

Then we have supply chain planning. Planning is the bridge that connects your big strategy to your daily management. It is the set of processes that decides what you need to produce, when you need to produce it, and where it needs to go. Planning happens over different time horizons. You have strategic planning that looks years ahead, tactical planning that looks at the next few months, and operational planning that looks at the next few days. When these three layers are aligned, everything runs like clockwork. When they are not, you end up with the “firefighting” we mentioned earlier.

The Essential Components of an End to End Supply Chain Strategy

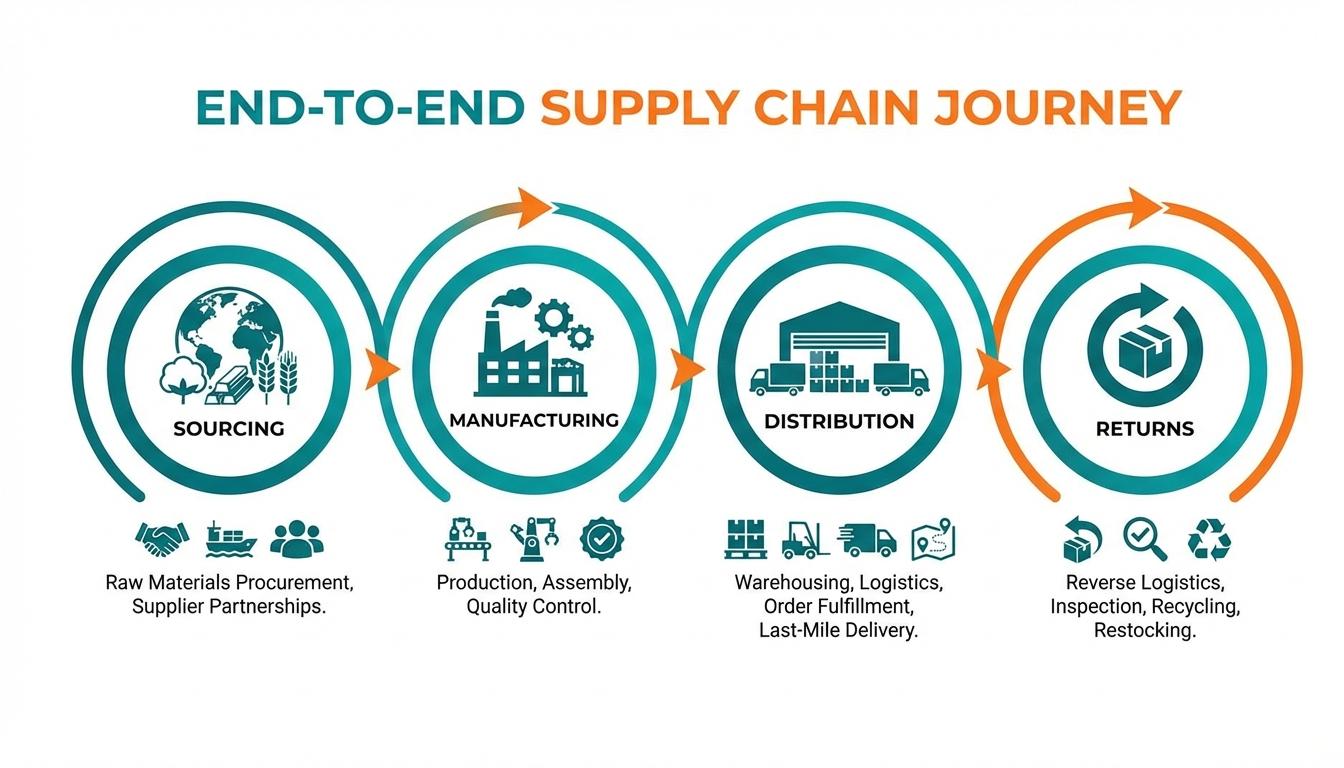

If you are going to build an end to end supply chain strategy, you cannot just look at one part of the business. You have to look at the whole journey. This starts from the moment a raw material is pulled from the ground and ends when the finished product reaches the customer. Here is what actually matters in that journey.

1. Sourcing and Procurement

This is the beginning of the chain. Your sourcing strategy determines who your partners are and where your materials come from. Are you going to use a single supplier to get a better price, or multiple suppliers to reduce risk? We have seen many companies move toward “near-shoring” recently, which means finding suppliers closer to home to avoid long shipping delays. This part of the strategy is about more than just negotiating prices. It is about building relationships that can survive a crisis.

2. Manufacturing and Operations

Once you have the materials, you have to make the product. Your strategy here defines where and how you produce goods. Should you own your own factories or outsource to a partner? Do you make products in large batches to save money, or do you make them to order to reduce waste? These choices have a massive impact on your flexibility and your cash flow. You will want to pay attention to this part because it is where most of your costs are often hidden.

3. Distribution and Logistics

How do your products get to the customer? This involves warehousing, transportation, and order fulfillment. Your strategy here determines your network design. Maybe you need one giant central warehouse, or perhaps twenty smaller ones spread across the country. According to industry leaders at Strategy+Business, how you configure this network is one of the most important drivers of total cost and service levels.

4. Returns and the Circular Economy

Here is something most guides do not mention. What happens when a customer sends something back? In the past, returns were an afterthought. Today, they are a critical part of the strategy. A good “reverse logistics” plan can recover value from returned goods and keep customers happy. It is also becoming a key part of sustainability efforts. If you can refurbish and resell products, you are helping the planet and your bottom line at the same time.

Choosing Your Strategic Archetype

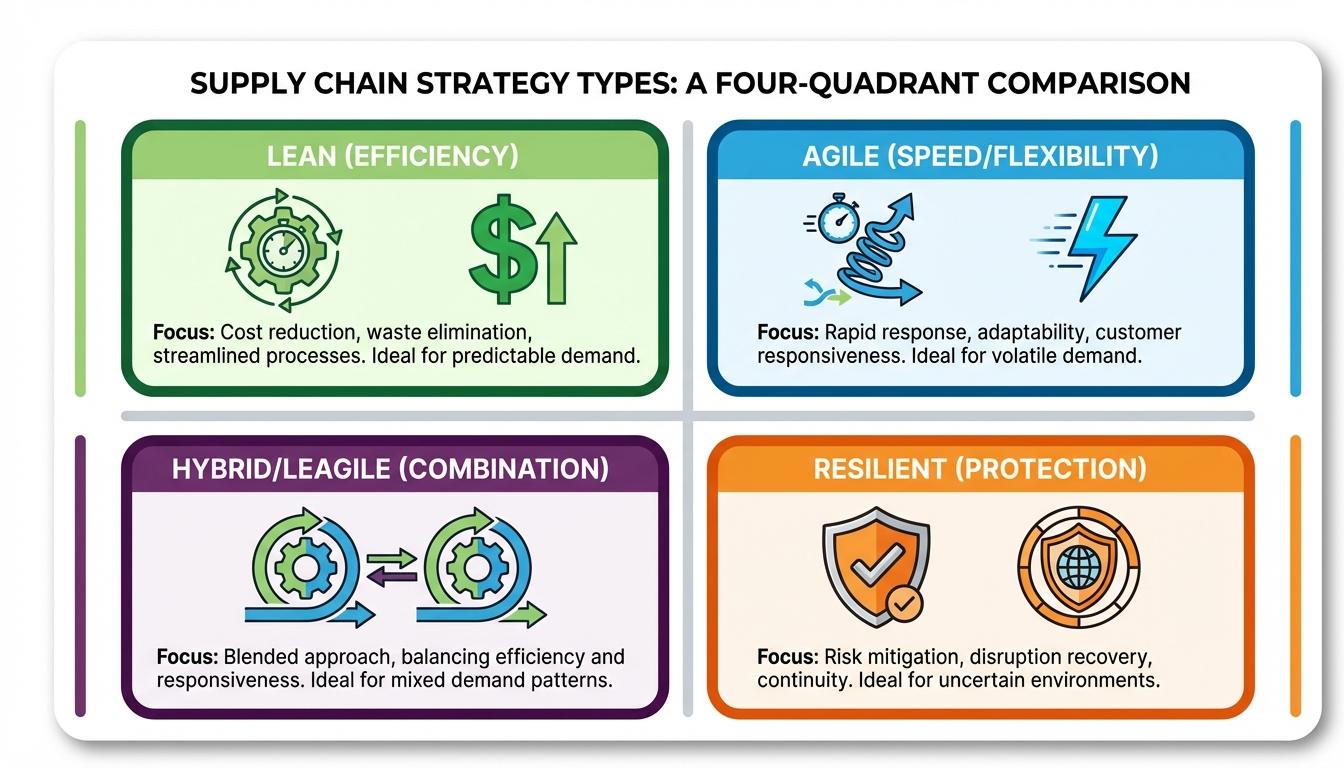

Not every supply chain should look the same. A company that sells high end fashion needs a very different strategy than a company that sells bulk bags of flour. What we found is that most successful strategies fall into a few specific categories. You might be wondering which one is right for you. Let us look at the most common types.

The Lean Strategy (Cost Efficient)

The goal here is simple. Minimize waste and lower costs. This strategy works best for products with stable demand and a lot of competition on price. Think of basic groceries or office supplies. You focus on high volume, standardized products, and tight inventory control. It is efficient, but it can be brittle. If something unexpected happens, a lean chain often lacks the “padding” to absorb the shock.

The Agile Strategy (Responsive)

If your market changes fast, you need an agile strategy. This is common in technology and fashion where product life cycles are short. The goal is speed and flexibility. You might keep extra capacity or use faster transportation methods. You are willing to pay a little more in costs to make sure you never miss a sale. It is about being the first to react when a new trend hits the market.

The Hybrid or “Leagile” Strategy

Most modern businesses actually use a mix. This is where it gets interesting. You might use a lean strategy for the parts of your process that are predictable, and an agile strategy for the parts that are volatile. For example, you might manufacture a generic base product cheaply in large batches (lean) but wait to add the final custom features until a customer places an order (agile). This is often called “postponement,” and it is a brilliant way to get the best of both worlds.

The Resilient Strategy

After the global disruptions of the last few years, resilience has become its own strategy. This approach prioritizes safety over pure efficiency. It involves keeping extra inventory, using multiple suppliers in different regions, and investing heavily in risk management. It might be more expensive in the short term, but it ensures you are the only one still shipping products when a crisis hits. For many companies, this is no longer optional. It is a necessity.

Setting Supply chain Objectives and Choosing KPIs

You cannot manage what you do not measure. This is an old saying, but it is true. However, the problem is that many companies measure the wrong things. They focus on local metrics, like how much a specific warehouse spent on electricity, instead of looking at the big picture. To build an effective strategy, you need to align your objectives with your business goals. For a comprehensive list of what to track, check out our article on supply chain KPIs.

What does this actually mean for you? It means your KPIs should tell a story about your strategy. If your strategy is to be the fastest in the market, your main KPI should be “Order Cycle Time.” If your strategy is to be the most reliable, you should focus on “On-Time In-Full” (OTIF) delivery. Here are some of the most important objectives to consider.

- Total Delivered Cost: Not just the price of the item, but the cost of the whole journey.

- Inventory Turnover: How quickly you are selling what you buy.

- Forecast Accuracy: How well you can predict what customers will want.

- Cash-to-Cash Cycle Time: How long it takes for cash spent on materials to come back as cash from a sale.

Remember, your KPIs are like the dashboard in your car. They should tell you if you are heading in the right direction and if you are running out of fuel. If you have too many metrics, you will get distracted. Pick the five or six that truly define success for your specific strategy.

Alignment: The Secret Sauce of Strategic Success

We have seen many brilliant strategies fail because they were built in a vacuum. A strategy is just a document until the whole company gets behind it. This is what we call supply chain alignment. It is the process of making sure your operations, your sales team, and your finance department are all rowing in the same direction.

Think about it. If your marketing team launches a massive “Buy One Get One Free” sale without telling the supply chain team, you are going to run out of stock. Customers will be angry, and your staff will be stressed. This is a classic lack of alignment. To fix this, many companies use a process called Sales and Operations Planning (S&OP). This is a monthly meeting where leaders from every department sit down and agree on one single plan for the business. It sounds simple, but it is incredibly powerful.

Aligning with External Partners

Your alignment should not stop at your own front door. You also need to align with your suppliers and your logistics providers. Do they know what your goals are? Are you measuring them on the same KPIs that you use to measure yourself? When you treat your suppliers as partners instead of just vendors, you can share data and solve problems together. This collaboration is what creates a truly seamless end to end supply chain.

The Importance of End to End Visibility

Have you ever tried to finish a jigsaw puzzle in the dark? That is what it feels like to manage a supply chain without visibility. You know the pieces are there, but you cannot see how they fit together. End to end visibility means having a near real time view of where your products are, from the raw material stage all the way to the customer’s doorstep.

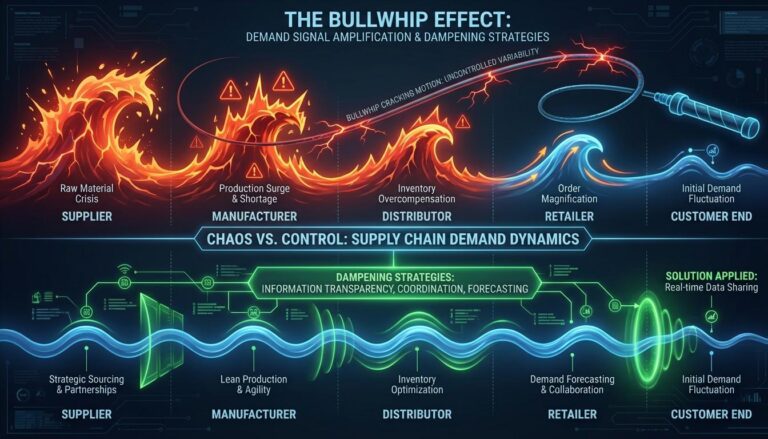

This visibility is essential because it helps you fight the “bullwhip effect.” This is a phenomenon where small changes in customer demand cause massive, erratic swings in inventory levels further up the chain. To understand why this happens and how to stop it, you should read our deep dive on the bullwhip effect in supply chain. When everyone has the same data, the bullwhip effect is minimized, and everyone can operate with less safety stock and lower costs.

Here is something most people miss. Visibility is not just about technology. It is about transparency. It is about being willing to share your demand forecasts with your suppliers so they can prepare. It is about your shipping partners telling you immediately when a truck is delayed instead of waiting until the next day. This level of openness builds trust and makes the whole chain more resilient.

A Step-by-Step Framework for Building Your Strategy

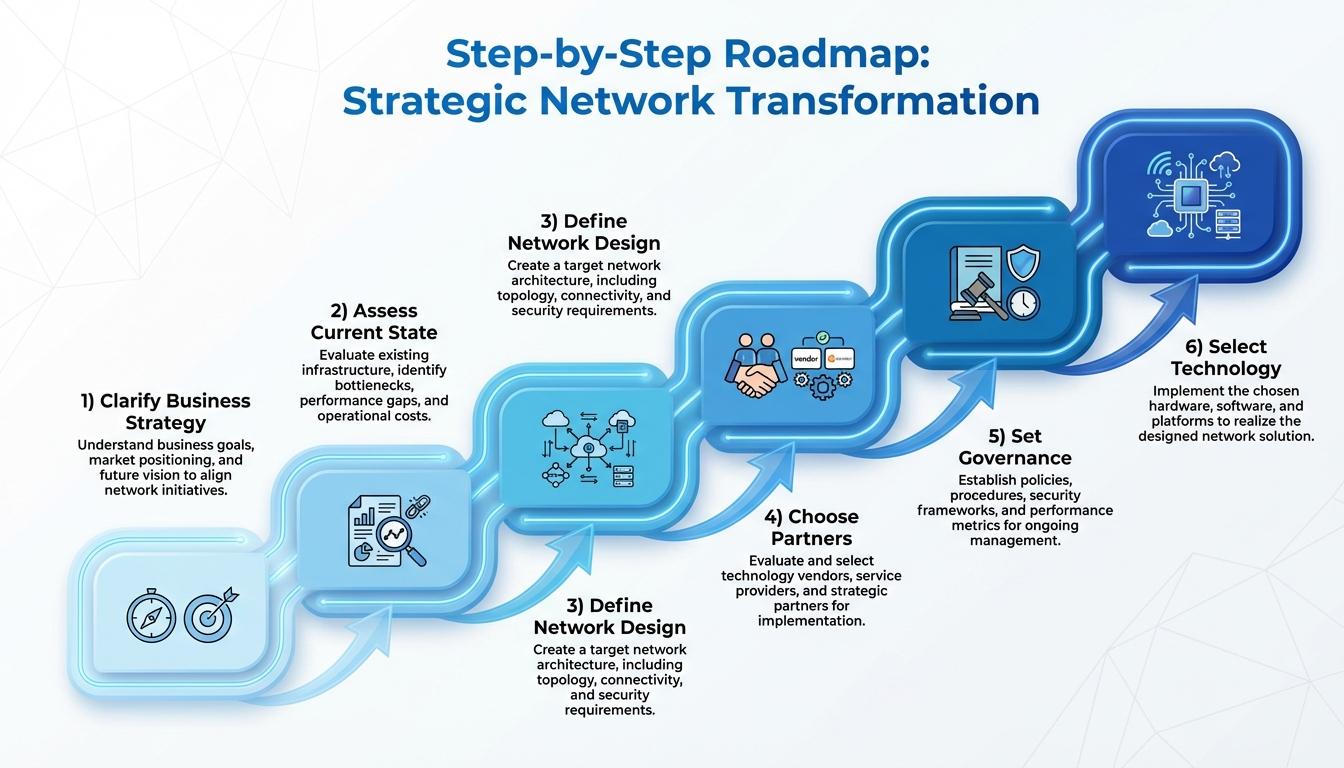

Ready to start building? We have broken the process down into a simple framework you can follow. Do not try to do this all in one day. Take your time to get it right, because this plan will guide your business for years to come.

- Clarify Your Business Strategy: Are you trying to be the lowest cost leader or a premium service provider? You cannot build a supply chain strategy until you know what the business is trying to achieve.

- Assess Your Current State: Be honest about what is working and what is not. Map out your current network, calculate your total costs, and talk to your customers about their frustrations.

- Define Your Network Design: Decide where your “nodes” should be. This includes factories, warehouses, and distribution centers. Use data to find the locations that offer the best balance of cost and service.

- Choose Your Partners: Select suppliers and logistics providers that align with your strategy. If you want to be agile, look for partners who are flexible and tech-savvy.

- Set Your Governance and Metrics: Decide who is responsible for which decisions. Establish your KPIs and a regular schedule for reviewing them.

- Select Your Technology: Invest in the tools that support your specific goals. If visibility is your priority, look for a platform that offers real time tracking.

The good news is that you do not have to be a giant corporation to do this. Even small businesses can benefit from going through these steps. It is all about being intentional instead of reactive.

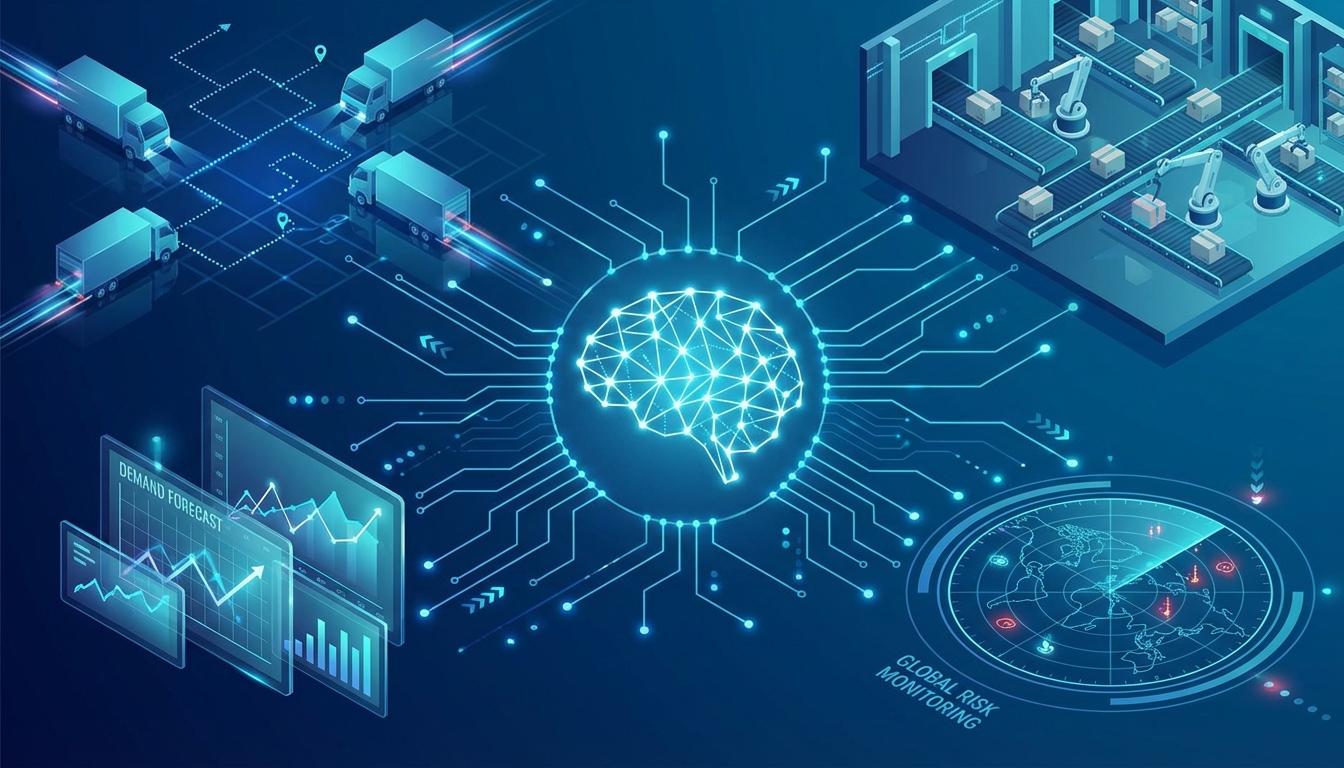

How AI and Technology Are Changing the Game

We cannot talk about supply chain strategy without talking about technology. We are currently seeing a massive shift in how operations are managed, thanks to Artificial Intelligence (AI) and advanced analytics. This is not just about robots in warehouses, although that is part of it. It is about using data to make better decisions.

According to research from Gartner, AI is becoming a core component of modern supply chain planning. Here is how it actually helps in real life.

- Predictive Demand Forecasting: AI can look at weather patterns, social media trends, and economic data to predict what people will buy more accurately than traditional statistical methods alone.

- Route Optimization: Algorithms can find the fastest and most fuel efficient routes for delivery trucks, supporting significant savings in logistics costs.

- Warehouse Automation: Smart systems can organize a warehouse based on which items are sold together, reducing the time it takes to pick and pack orders.

- Risk Monitoring: AI can scan global news and weather reports to alert you to potential disruptions before they even happen.

But here is a word of caution. Technology is a tool, not a strategy. We have seen companies spend millions on fancy software only to find it does not help because their basic processes were broken. Fix your strategy first, then use technology to make that strategy move faster. That is the secret to success.

Best Practices for a Modern Supply Chain Strategy

If you have made it this far, you are already ahead of most people. You understand that a strategy is a living thing that needs constant attention. To wrap things up, we want to share a few best practices that we have observed from the world’s most successful supply chains.

First, stay customer-centric. Every decision you make should ultimately benefit the person who buys your product. If a cost-cutting measure makes the customer’s experience worse, it is probably a bad idea in the long run. Second, be data-driven. Stop making decisions based on “gut feelings” or how things were done ten years ago. Use the data you have to find the truth.

Third, keep it simple. The best strategies are easy to understand and easy to explain. If your employees cannot explain the strategy in two sentences, it is probably too complicated. Finally, stay flexible. The world changes fast. Your strategy should be reviewed at least once a year to make sure it still makes sense in the current market. Resilience is not just about inventory. It is about the ability to change your mind when the facts change.

Frequently Asked Questions

What is the biggest mistake people make with supply chain strategy?

The biggest mistake is focusing solely on cost reduction. While saving money is important, if you cut costs so deeply that you lose the ability to respond to customers or handle disruptions, your business will suffer in the long run. A good strategy balances cost with service and resilience.

How often should we update our strategy?

This comes up a lot, and the answer is that you should do a deep dive review at least once a year. However, you should also be monitoring your KPIs monthly. If you see a major shift in the market or a massive disruption, do not wait for the annual review. Update your plan immediately.

Can a small business have a supply chain strategy?

Absolutely. In fact, small businesses often need one more than large ones because they have less room for error. Your strategy might be as simple as deciding to source from local vendors to ensure quality and speed, or using a third party logistics (3PL) provider to handle your shipping so you can focus on sales.

How does sustainability fit into the strategy?

Sustainability is no longer a “nice to have” part of the plan. It is a core component. This involves choosing ethical suppliers, reducing carbon emissions in transportation, and designing products that are easy to recycle. Modern customers are looking for companies that care about their impact on the world.

Is AI necessary for a good strategy?

AI is a powerful tool, but it is not strictly necessary for every business. If you are a small company with a simple product line, you can build a great strategy using basic data and good relationships. However, as you grow and your complexity increases, AI will become much more valuable for managing the noise.

What is the difference between a lean and an agile supply chain?

The short answer is that lean is about efficiency and cost, while agile is about speed and flexibility. Lean works best for predictable products like toothbrushes, while agile works best for unpredictable products like high fashion or new electronics. Most companies use a hybrid of both.

Final Thoughts on Building Your Strategy

We have covered a lot of ground today. We have looked at what a supply chain strategy is, why it differs from daily management, and the different archetypes you can choose from. We have also explored the importance of alignment, visibility, and the exciting world of AI. It might seem like a lot to take in, but remember that you do not have to do it all at once.

The most important thing you can do right now is to stop and look at your current operations. Are you following a plan, or are you just reacting to the latest crisis? If it is the latter, do not worry. You now have the framework and the tools to start building something better. Start with your business goals, talk to your team, and begin mapping out a journey that leads to growth rather than just survival.

A well built supply chain strategy is more than just a document in a drawer. It is the heartbeat of your business. It is what allows you to keep your promises to your customers while still making a profit. You have got the knowledge. Now it is time to take that first step. What part of your supply chain are you going to focus on first? We are rooting for you.