Inventory Management Methods: Choosing the Right Approach

Have you ever walked into a store looking for something specific, only to find an empty shelf? Or maybe you have seen a warehouse overflowing with boxes that look like they have been gathering dust for years. Both of these situations are classic symptoms of the same problem. The balance is off. Finding that perfect middle ground where you have exactly what you need without drowning in extra stock is what we are talking about today. If you have been searching for the right inventory management methods to fix your business or just to understand the industry better, you are in the right place.

We get it. The world of supply chain management can feel like a maze of acronyms and complex math. You might feel overwhelmed by the sheer number of systems out there. It is easy to think that you need a massive team or a million dollar budget to get this right. The reality is quite different. Most of the time, the best approach is about picking a few smart strategies and using them consistently. We have looked into how the biggest players and the most agile startups handle their stock, and we want to share that with you in a way that actually makes sense.

This guide is designed to be your ultimate resource. We are going to start with the foundational concepts that every manager needs to know. From there, we will move into specific stock control techniques like FIFO, LIFO, and the ever important ABC analysis. We will even talk about the technology that makes it all possible. By the time you finish reading, you will have a clear roadmap for optimizing your own inventory. Let us break this down and see how we can turn your inventory from a headache into a competitive advantage.

What is Inventory Management Really About?

At its simplest level, inventory management is the process of ordering, storing, and using a company’s goods. This includes everything from the raw materials used to build a product to the finished items that land on a customer’s doorstep. But if we are being honest, it is about much more than just “stuff.” It is about cash. Every item sitting on a shelf represents money that you cannot spend on marketing, hiring, or expansion. That is why getting this right is so critical for your bottom line.

The main goal is to ensure you have the right products available at the right time. We want to avoid stockouts because losing a sale is painful. At the same time, we want to minimize the total cost of holding that inventory. This includes the cost of the warehouse space, insurance, and the risk that the items might break or go out of style. It is a delicate balancing act. When we manage inventory well, we improve our cash flow and make our whole operation run like a well oiled machine.

The Different Faces of Inventory

Before we can manage it, we have to know what we are looking at. Not all inventory is created equal. Most businesses deal with a few specific types, and each one requires a slightly different touch. Here is what you will usually encounter in the wild.

- Raw Materials: These are the basic components used to manufacture your goods. Think of flour for a bakery or steel for a car manufacturer.

- Work in Process (WIP): These are items that are currently being worked on. They are not raw anymore, but they are not ready to be sold yet either.

- Finished Goods: These are the products that are ready for your customers to buy. This is usually what people think of when they hear the word “inventory.”

- MRO Supplies: This stands for Maintenance, Repair, and Operations. These are things like light bulbs, cleaning supplies, or tools that keep the business running but are not sold to customers.

- Transit Stock: This is inventory that is currently moving between locations, like on a truck or a ship.

What we found is that many businesses struggle because they try to treat all these types the same way. In reality, your strategy for raw materials might be completely different from how you handle your finished goods. Understanding these distinctions is the first step toward true optimization.

The Foundations of Inventory Flow and Valuation

How do you decide which items to sell first? And how do you put a dollar value on the items left on your shelf? These might sound like questions for an accountant, but they have huge implications for your daily operations. The way you flow your inventory determines your waste levels, while the way you value it affects your taxes and profit reports. Let us look at the most common methods used today.

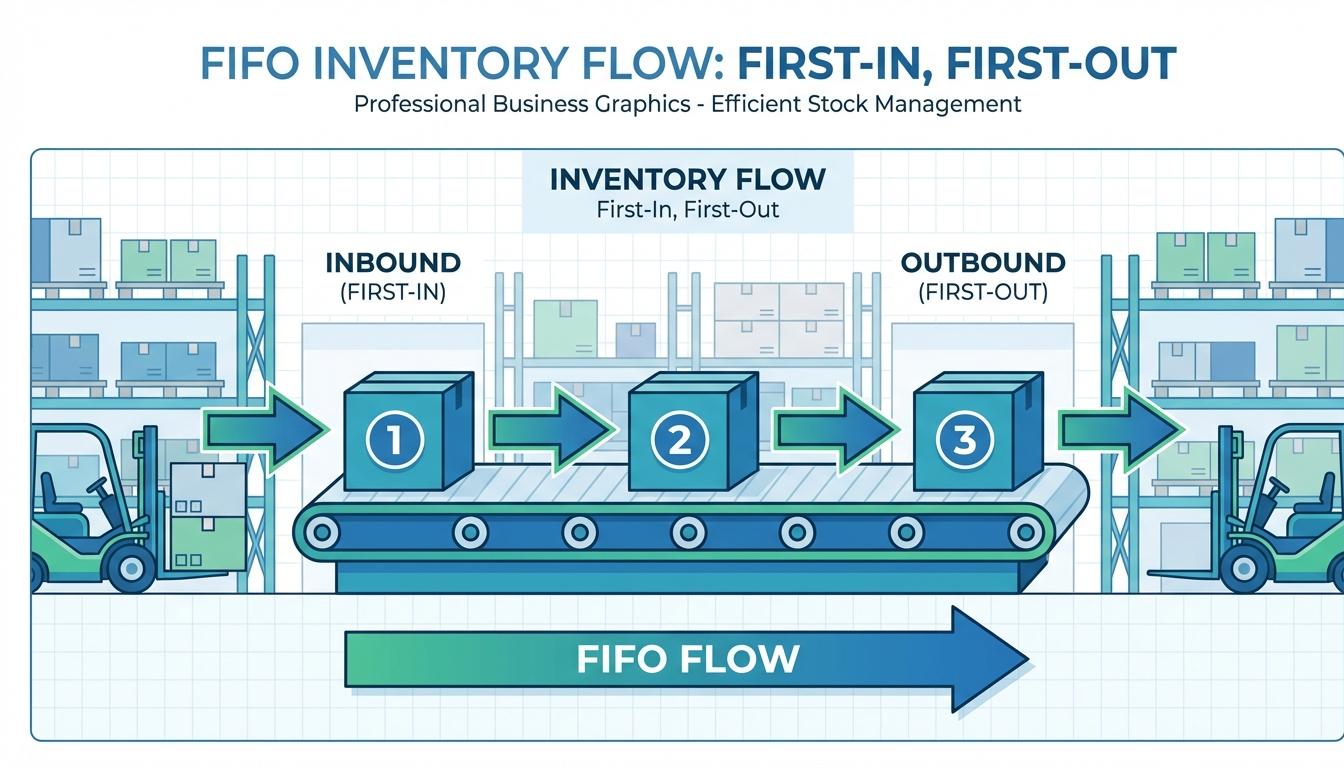

FIFO (First-In, First-Out)

This is exactly what it sounds like. The oldest items in your inventory are the ones you sell or use first. If you are dealing with anything that can expire, like food, medicine, or even high tech electronics that might become obsolete, FIFO is usually your best friend. It keeps your stock fresh and reduces the chance that you will have to throw money away because of spoilage.

From an accounting perspective, FIFO is very popular. When prices are rising, FIFO shows a higher ending inventory value and higher profits. Why? Because the items you are selling are the older, cheaper ones you bought a while ago. This makes your balance sheet look great, but it might mean you pay a bit more in taxes. Most businesses find the physical benefits of FIFO outweigh the tax implications.

LIFO (Last-In, First-Out)

LIFO is the rebel of the inventory world. It assumes that the items you bought most recently are the ones you sell first. In a warehouse, this would be like taking the box off the very top of the stack. While this is rarely used as a physical way to handle goods, it is sometimes used for accounting in the United States under GAAP rules. However, international standards usually do not allow it.

The logic behind LIFO is often about taxes. In times of inflation, the most recent items you bought are the most expensive. By “selling” those first on paper, your cost of goods sold goes up, and your taxable income goes down. Here is the practical takeaway. Unless you have a very specific accounting reason to use LIFO, you should probably stick with FIFO for your physical stock management. It is more natural and much less risky.

Weighted Average Cost

Sometimes, it is impossible to track every single unit. If you are selling thousands of identical bolts or gallons of chemicals, trying to figure out which “batch” a specific item came from is a nightmare. This is where weighted average cost comes in. You simply take the total cost of all the items you have and divide it by the total number of units. It provides a steady, middle of the road value that smooths out price fluctuations. It is simple, effective, and keeps your hair from turning gray.

Replenishment Strategies: When to Order More

This is the part of inventory management where most people get confused. How do you know exactly when to pick up the phone and call your supplier? If you order too early, you run out of space. If you order too late, you have angry customers. The good news is that there are proven formulas and methods to take the guesswork out of this process.

The Reorder Point (ROP) Method

Think of the Reorder Point as your “line in the sand.” It is a specific inventory level that, once reached, triggers a new order. To calculate this, you need to know how much you sell on average every day and how long it takes for a new shipment to arrive. This time between ordering and receiving is called “lead time.”

The formula is usually: (Average Daily Sales x Lead Time) + Safety Stock. This ensures that while you are waiting for the new truck to arrive, you still have enough on the shelves to keep selling. It is a proactive approach that works beautifully for items with steady demand. If you want to dive deeper into how to protect yourself from surprises, check out our guide on safety stock calculation formulas.

Economic Order Quantity (EOQ)

While the Reorder Point tells you when to order, the Economic Order Quantity tells you how much to order. Every time you place an order, it costs you money in shipping and administrative time. But every item you keep in the warehouse also costs you money in holding fees. EOQ is the mathematical sweet spot where these two costs are at their lowest.

It is a bit of a classic model, and while it assumes things like constant demand and stable prices, it is a fantastic starting point for any business. It keeps you from making the mistake of ordering huge amounts just to get a small discount, only to realize you have no place to put it all. For the full breakdown of the math behind this, you can read our economic order quantity guide.

Periodic Review Method

Not every business wants to monitor every item every second of the day. Some find it easier to check their stock at fixed intervals, like every Monday morning or the first of the month. This is the periodic review method. You check what you have, and you order enough to get back up to your “target” level. This is great for small businesses or for products that are always delivered on a specific schedule by a vendor.

Advanced Strategies: Lean and Collaborative Inventory

Once you have the basics down, you might want to look at how the world’s most efficient supply chains operate. These strategies are less about formulas and more about the philosophy of how you run your business. They require more trust and better communication, but the rewards are massive.

Just-in-Time (JIT) Inventory

JIT is the ultimate goal for many manufacturing and retail companies. The idea is to have inventory arrive exactly when it is needed for production or a sale, and not a moment sooner. It was famously developed and refined by Toyota and has since changed the world. When JIT works, it is beautiful. You have almost no money tied up in stock, and your warehouse can be much smaller.

However, we have to be real here. JIT is risky. If a supplier is late or a ship gets stuck in a canal, you have zero “buffer” to protect you. Your whole operation could grind to a halt. In recent years, many companies have moved away from “pure” JIT toward a “just in case” model that keeps a little more safety stock on hand. It is all about your personal risk tolerance and how much you trust your supply chain.

Vendor-Managed Inventory (VMI)

Imagine if your supplier was responsible for making sure you never ran out of stock. That is Vendor-Managed Inventory. You share your sales data with your supplier, and they decide when to send more. This sounds like a dream for many business owners because it takes the task of ordering off your plate. It also helps the supplier because they can plan their production better based on your actual needs.

The catch? You have to be willing to be an open book. You need to share real time data and have a very strong relationship with your vendors. According to research by industry experts, companies that use VMI often see a significant reduction in stockouts and lower overall inventory levels. It is a partnership in the truest sense of the word.

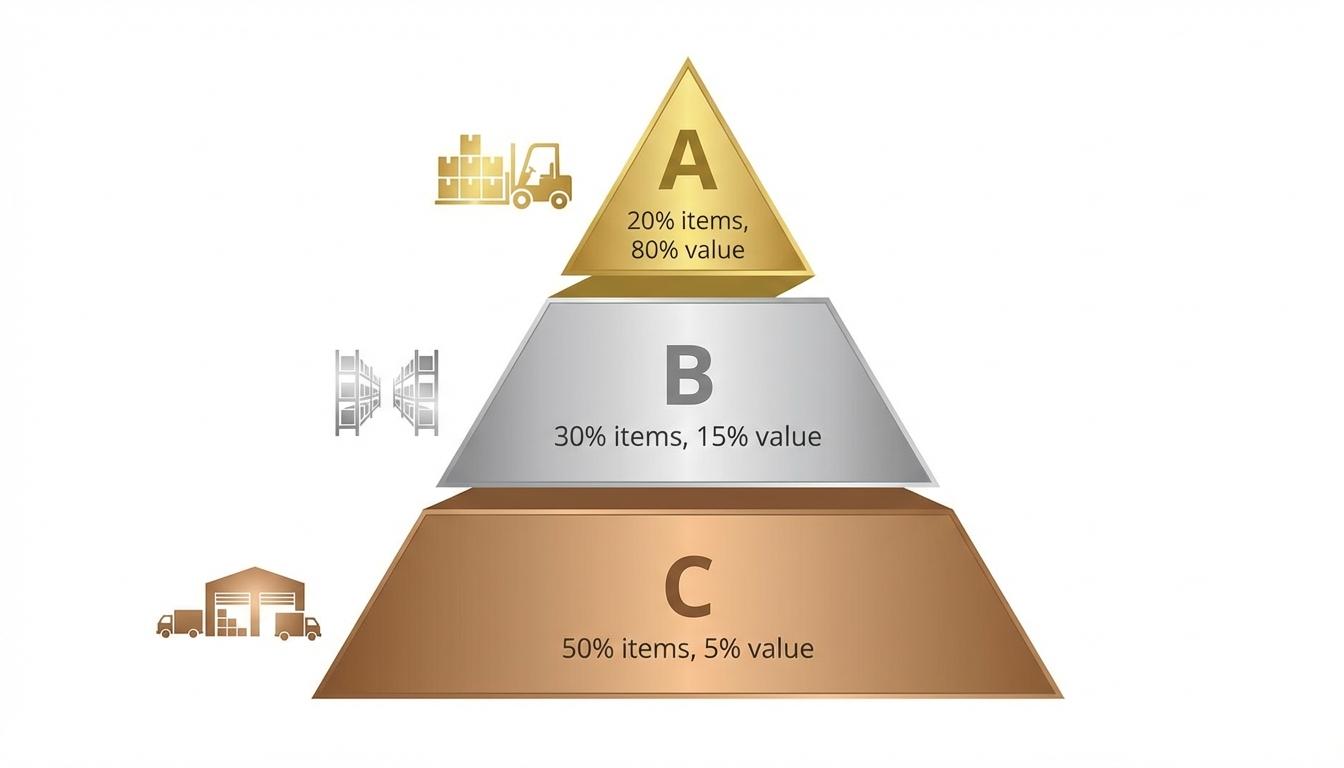

Prioritizing Your Efforts with ABC Analysis

Here is something most guides do not mention. You should not be spending the same amount of time managing every item in your warehouse. Some items are worth much more than others, and some sell way faster. If you treat a pack of paperclips the same way you treat a high end laptop, you are wasting your time. This is where ABC analysis comes in.

ABC analysis is based on the Pareto Principle, which says that 80 percent of your results usually come from 20 percent of your efforts. In inventory terms, about 20 percent of your items usually account for 80 percent of your total value. We categorize items like this:

- A-Items: These are your VIPs. They are high value or high priority. They need tight control, frequent counts, and very accurate records.

- B-Items: These are your middle class. They are important, but they do not need the same level of obsessive attention as A-items. Standard automated rules usually work fine here.

- C-Items: These are the “tail” of your inventory. They are low value and easy to replace. You can afford to keep more of them on hand and check them less often because the cost of holding them is low.

By using this method, you focus your brainpower where it actually makes a difference. To see how to set this up for your own warehouse, take a look at our ABC inventory classification guide. It is one of the fastest ways to see an immediate improvement in your efficiency.

Maintaining Accuracy: Perpetual vs. Periodic Systems

You can have the best strategy in the world, but if your data is wrong, your strategy will fail. Keeping your “on-hand” numbers accurate is one of the hardest parts of inventory management. There are two main ways to handle this, and the choice usually depends on your technology and the size of your business.

The Perpetual Inventory System

In a perpetual system, your inventory records are updated in real time. Every time a barcode is scanned at a register or a warehouse worker picks an item, the system instantly subtracts it from your totals. This gives you a “god’s eye view” of your stock levels at any given moment. This is what most modern businesses use today. It is essential for ecommerce because you never want to sell an item online that you don’t actually have in the warehouse.

The good news is that this technology has become very affordable. Even small Shopify or Amazon sellers can use perpetual systems. The challenge is that it requires discipline. If someone moves a box without scanning it, your system is now “lying” to you. That is why we still need physical checks.

The Periodic Inventory System

A periodic system is much more old school. You don’t track every sale in real time. Instead, you wait until the end of a period, like a week or a month, and you go out and count everything by hand. You use that count to figure out your cost of goods sold and your ending inventory. It is simple and requires almost no technology, but it is very reactive. You might not realize you are out of stock until you go to do your count. For most growing businesses, this is not enough.

Cycle Counting: The Secret to High Accuracy

If you are using a perpetual system, you might think you never need to count your stock by hand. Unfortunately, that is not true. Small errors happen. Cycle counting is the solution. Instead of shutting down the whole warehouse once a year for a massive “physical inventory” count, you count a small portion of your items every single day. Over the course of a few months, you end up counting everything. It keeps your data clean without the headache of a massive annual shutdown.

The Role of Technology and Systems

We live in an era where you don’t have to do all this math on a napkin. Modern inventory control systems handle the heavy lifting for you. Whether you are using a simple app or a massive Enterprise Resource Planning (ERP) system, the software should be doing a few key things for you.

First, it should provide visibility. You should know what you have and where it is across all your locations. Second, it should automate your reordering. A good system will tell you exactly when you hit your reorder point and can even generate the purchase order for you. Third, it should integrate with your other tools. Your inventory software needs to talk to your accounting software and your sales platforms.

We are also seeing some incredible advancements in automation. Technologies like RFID (Radio Frequency Identification) allow you to scan an entire pallet of goods in seconds without opening a single box. IoT sensors can monitor the temperature of perishable goods and alert you before they spoil. While you might not need these on day one, it is exciting to see where the industry is heading. According to Gartner, AI and machine learning are increasingly being used to predict demand more accurately than any human ever could.

How to Choose the Right Method for Your Business

At this point, you might be thinking, “This all sounds great, but which one do I actually pick?” The truth is that most successful companies use a hybrid approach. They don’t just pick one method and call it a day. They combine them based on their specific needs. Here is how you might think about it.

If you are a manufacturer, you will likely lean heavily on JIT and Lean principles to keep your production line moving. You will use a perpetual system to track raw materials and finished goods, and you will probably use ABC analysis to make sure your most critical components never run out.

If you are in retail or ecommerce, your focus will be on perpetual tracking and reorder points. You have to manage many different SKUs (Stock Keeping Units), so automation is your best friend. You will want to use FIFO to keep your stock fresh and avoid obsolescence. Collaborative tools like VMI might be useful for your top selling items.

For those in wholesale or distribution, the name of the game is service level. You are the middleman, so your customers expect you to have what they need immediately. You will likely focus on EOQ to keep your shipping costs down and use sophisticated forecasting tools to stay ahead of demand trends.

The bottom line is that your inventory strategy should grow with you. What worked when you were shipping out of a garage won’t work when you have three warehouses. Start with the basics, get your data clean, and then start layering on more advanced techniques like safety stock optimization and vendor collaboration.

Frequently Asked Questions

What is the best inventory management method for a small ecommerce business?

For most small ecommerce businesses, we recommend a combination of a perpetual inventory system and the Reorder Point (ROP) method. This ensures you have real time visibility into your stock across multiple sales channels and automates the replenishment process so you don’t have to manually check shelves. Adding a basic ABC analysis will also help you focus your time on the 20 percent of products that drive most of your sales.

How often should I do a physical count of my inventory?

While an annual full count is often required for tax purposes, we strongly suggest implementing cycle counting. By counting a few items every day, you can maintain much higher accuracy throughout the year. Most high performing warehouses aim to count their “A-items” at least once a quarter, while “C-items” might only be counted once or twice a year.

Is JIT (Just-in-Time) too risky for a small business?

It can be. JIT requires a very high level of coordination and extremely reliable suppliers. For a small business, a single delayed shipment can be devastating. We usually suggest a “Lean” approach instead, which aims to reduce waste but still keeps a healthy amount of safety stock on hand to protect against supply chain disruptions.

What is the difference between an SKU and a barcode?

This is a common point of confusion. An SKU (Stock Keeping Unit) is an internal alphanumeric code that you create to identify your products. A barcode is the machine readable pattern used to track that item. You can have your own SKU for a product, but that product might have a universal barcode (like a UPC) that is used by every store that sells it.

Can I manage my inventory using just Excel?

You can, but we usually don’t recommend it once you move past a handful of items. Excel is prone to human error, it doesn’t update in real time, and it doesn’t easily talk to your online store or shipping software. There are many affordable, dedicated inventory tools that will save you hours of manual work and prevent costly mistakes.

What are carrying costs and why do they matter?

Carrying costs are the hidden expenses of holding inventory. This includes the cost of the warehouse space, insurance, labor to move the items, and the “opportunity cost” of the money tied up in the stock. Typically, carrying costs are often estimated in the range of 20 percent to 30 percent of the total value of your inventory per year. Reducing these costs is one of the fastest ways to improve your business’s profitability.

Final Thoughts on Mastering Your Stock

We have covered a lot of ground today. From the foundational logic of FIFO to the high tech world of automated tracking, it is clear that inventory management methods are the heartbeat of any successful product based business. It is easy to look at all these formulas and feel like it is too much to take on at once. But remember, you don’t have to be perfect on day one. The most important thing is to start moving in the right direction.

Begin by getting a clear picture of what you have right now. Implement a perpetual tracking system if you haven’t already. Use ABC analysis to identify your most important items and give them the attention they deserve. Once you have the basics under control, you can start experimenting with things like EOQ or exploring collaborative partnerships with your vendors. You will be surprised at how much stress disappears when you finally trust your numbers.

The goal isn’t just to have a tidy warehouse. The goal is to have a business that is resilient, profitable, and ready to grow. When you master your inventory, you free up the cash and the time you need to focus on what you really love doing. You have the tools and the knowledge now. The next step is simply to take action. You have got this.

If you found this guide helpful, why not share it with someone else who might be struggling with their stock? And if you have questions we didn’t answer here, feel free to explore our other resources on supply chain optimization. There is always more to learn on this journey.