Building Sustainable Logistics Operations for the Future

Ever look at a delivery truck and wonder about the journey those packages took before arriving at your door? We see the trucks and the boxes, but we rarely see the massive, invisible web of movement happening every second. This web is what we call logistics. For decades, the goal of this system was simple. It was all about moving things as fast and as cheaply as possible. But there is a problem. That old way of doing things is taking a serious toll on our planet and our communities. That is why we are here to talk about sustainable logistics.

If you have been trying to wrap your head around how to make shipping or warehousing more “green,” you are not alone. It can feel like a massive puzzle with too many moving parts. You might be hearing terms like green supply chain or low carbon logistics and wondering if they all mean the same thing. The truth is that while they are related, sustainable logistics is the big umbrella that covers it all. It is not just about being eco friendly. It is about building a system that can last for generations. We want to help you understand every corner of this topic, from the tailpipe emissions to the way workers are treated in a warehouse.

This guide is designed to be your definitive resource. We are going to look at the history of how logistics evolved, why the shift to sustainability is actually a smart business move, and the specific practices that make a difference. We will look at transportation, packaging, and even the “circular economy” that turns waste back into resources. Whether you are a business owner looking to optimize your operations or just someone curious about the future of the industry, we have got you covered. Let us get into it.

What Exactly Is Sustainable Logistics?

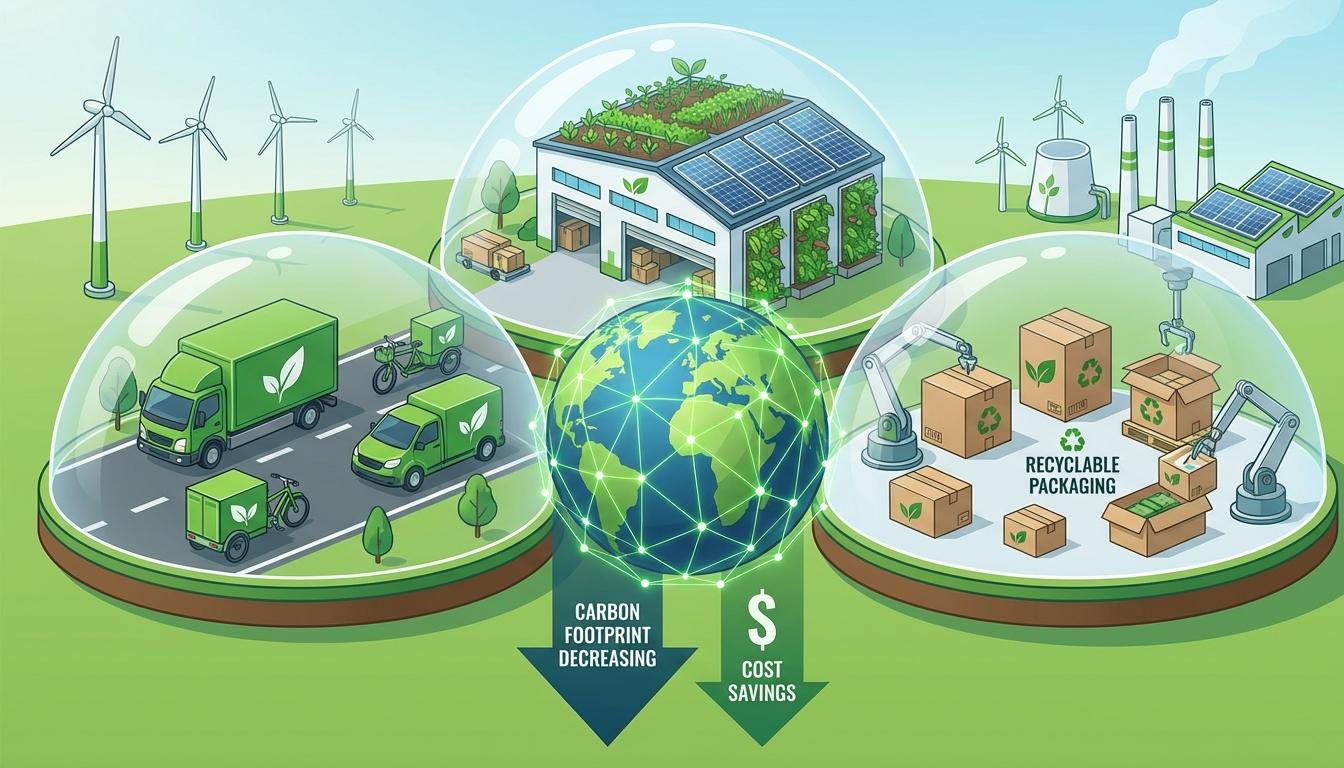

Let us start with the basics. In simple terms, sustainable logistics is the process of planning and moving goods in a way that minimizes damage to the environment and society while still keeping the business profitable. You might hear people call it green logistics or environmental logistics. While those terms often focus specifically on the planet, sustainable logistics goes a step further. It looks at what we call the three pillars of sustainability. These are the environmental, the social, and the economic impacts of doing business.

The environmental pillar is what most people think of first. This is about reducing greenhouse gas emissions, cutting down on waste, and saving energy. It is about making sure that the act of moving a product from point A to point B does not leave a trail of pollution behind it. Then there is the social pillar. This part is often overlooked, but it is just as important. It covers things like fair pay for drivers, safe working conditions in warehouses, and making sure logistics hubs do not ruin the quality of life for local communities. Finally, there is the economic pillar. Here is the bottom line. If a green solution is so expensive that it puts a company out of business, it is not actually sustainable. True sustainability means finding the sweet spot where being “good” also makes financial sense.

What we found is that sustainable logistics is not just a trend. It is a fundamental shift in how we think about the supply chain. In the past, logistics was viewed as a necessary evil or a cost to be cut. Today, it is seen as a way to create value. When we optimize a route to save fuel, we are saving money and the planet at the same time. When we design better packaging, we reduce waste and shipping costs. It is a win-win scenario that more companies are starting to embrace. According to the MIT Center for Transportation and Logistics, integrating these practices is increasingly important for companies that want to remain competitive in a changing global market.

The Evolution of the Industry

To understand where we are going, we have to look at where we started. Traditional logistics actually has its roots in military history. It was all about getting supplies to soldiers as quickly as possible. After World War II, businesses adopted these same principles to move products to consumers. For a long time, the only things that mattered were speed and cost. If a truck was half empty but needed to get somewhere fast, it went. If packaging was bulky but cheap, it was used. Nobody was really thinking about the long term consequences.

Things started to change in the 1970s and 80s. People began noticing things like acid rain and air pollution. This helped spur early discussions of what would later be called “green logistics” in places like Europe and North America. Scholars and policymakers realized that all those trucks and warehouses were contributing significantly to environmental degradation. By the 1990s, the conversation expanded. It was no longer just about the “green” stuff. It was about the entire supply chain. Today, we have moved into an era where climate change, urban congestion, and resource scarcity are driving the conversation. We are no longer just trying to do “less bad.” We are trying to build systems that are inherently better.

Why Does Sustainable Logistics Matter So Much?

You might be wondering why this has become such a hot topic lately. Is it just about PR? Let us be real for a moment. While some companies definitely use sustainability for marketing, the drivers behind this movement are very real and very urgent. Logistics is one of the significant contributors to global energy use and greenhouse gas emissions. If we do not change how we move things, we cannot meet our global climate goals. But beyond the planet, there are major economic and social reasons to make the switch.

First, let us talk about the environment. Freight transport is a heavy hitter when it comes to CO2 emissions. Sustainable practices aim to lower that footprint by using better fuels and smarter routes. We are also looking at reducing waste from packaging and protecting ecosystems from the noise and pollution caused by massive logistics hubs. Here is the practical takeaway. Every gallon of fuel saved is not just less carbon in the air, it is less money spent on overhead. Efficiency is the bridge between being eco friendly and being profitable.

Next, there are the economic drivers. This is the part most people miss. Sustainable logistics actually makes businesses more resilient. When you optimize your network and use different modes of transport, like rail or water instead of just trucks, you are less vulnerable to fuel price spikes or highway closures. Plus, customers are demanding it. People today want to know that the products they buy were delivered responsibly. If you can show that your delivery has a lower impact, you have a competitive advantage. You might even find it easier to comply with new regulations. Governments everywhere are tightening rules on emissions and waste. Getting ahead of those laws now saves you from massive fines later.

The Social and Regulatory Side

We cannot ignore the human element. Logistics happens in our backyards. Massive warehouses bring traffic and noise to neighborhoods. Exhaust from idling trucks affects the health of people living near ports. Sustainable logistics seeks to minimize these negative impacts. It also focuses on the people working within the system. This means ensuring that warehouse workers have safe, ergonomic environments and that drivers are not being pushed to the point of exhaustion. It is about respect and ethics.

From a regulatory standpoint, the pressure is mounting. Many regions are introducing carbon pricing and strict emissions standards. If you are not measuring your impact now, you are flying blind. To get started with understanding your own footprint, you can look into how to measure your logistics carbon footprint. Understanding the data is the first step toward making meaningful changes. Without data, you are just guessing. With it, you can prove your progress to stakeholders and regulators alike.

Core Practices: Sustainable Transportation

Transportation is usually the biggest piece of the logistics emissions pie. It is the most visible part of the process, and it is also the hardest to change. But the good news is that we have more tools than ever to make it cleaner. This is what we often call low carbon logistics or sustainable transportation. The goal here is to move the same amount of goods (or more) while burning less fuel and creating less pollution.

One of the most effective strategies is what we call “mode shifting.” This means moving freight from high emission vehicles, like airplanes or small trucks, to lower emission options like rail or inland waterways. Did you know that moving freight by train can be significantly more efficient than moving it by truck? Of course, you cannot always use a train to get a package to someone’s front door, but for long hauls, it is a game changer. Multimodal transport, which combines different methods, is the secret sauce to a greener fleet.

Another major focus is fleet efficiency and alternative fuels. This is where it gets interesting. We are seeing a surge in electric vehicles (EVs) for local deliveries. For longer hauls, companies are experimenting with hydrogen or biofuels. But even if you can’t buy a whole new fleet of electric trucks today, you can still make an impact. Simply upgrading to more aerodynamic trailers or better tires can save a significant amount of fuel over time. It is about making the most of what you have while planning for the future.

Route and Load Optimization

This is where technology really shines. Have you ever seen a delivery truck driving around half empty? That is a huge waste of resources. Load optimization is the practice of making sure every trip is as full as possible. This involves “backhauling,” where a truck picks up a new load after dropping one off, rather than returning empty. It also involves consolidating shipments from different customers to share the space. Fewer trips means less fuel, less traffic, and less wear and tear on the vehicles.

Then there is route planning. Modern AI and GPS data allow us to plan routes that avoid traffic jams and minimize idling time. We can even plan for “green waves” where trucks hit fewer red lights. In cities, we are seeing “last-mile” innovations like cargo bikes and parcel lockers. These reduce the need for big vans to circle city blocks looking for parking. According to the U.S. Environmental Protection Agency’s SmartWay program, these types of operational improvements can reduce fuel use by up to 20% without even changing the vehicles themselves.

Greening the Warehouse

While trucks get all the attention, warehouses are the silent giants of the logistics world. They use massive amounts of electricity for lighting, heating, and cooling. They also produce a lot of waste from packaging and handling. Sustainable warehousing is about turning these facilities from energy drains into efficient hubs. This is a huge part of logistics sustainability practices because warehouses are often under a company’s direct control.

The first step is usually the building itself. Energy-efficient lighting, like LEDs, is a no-brainer. They last longer and use a fraction of the power. Better insulation and smart HVAC systems can also make a huge difference, especially in climates with extreme temperatures. Some companies are even putting solar panels on their massive warehouse roofs. Since warehouses have so much surface area, they can often generate enough power to run their own operations and even charge their electric delivery fleets. It is a closed loop that saves money and carbon.

Automation and digitalization also play a role. When a warehouse uses a smart Warehouse Management System (WMS), it can optimize the “picking” routes for workers or robots. This means less movement, less energy use, and faster processing times. For more specific ideas on how to cut down on energy bills in your facility, you might want to check out these warehouse energy efficiency tips. Small changes in how you manage your space can lead to big savings over time.

Waste Management in Distribution Centers

Warehouses are also where a lot of waste happens. Think about all the plastic wrap, wooden pallets, and cardboard boxes that move through a facility every day. Sustainable logistics involves managing these “waste streams.” This means having robust recycling programs in place and looking for ways to reuse materials. For example, instead of throwing away damaged pallets, they can be repaired. Instead of single-use plastic wrap, some companies are moving toward reusable bands or wraps.

It is also about inventory management. If you have too much stock sitting in a warehouse, it might eventually become obsolete and end up in a landfill. Better demand forecasting helps companies keep only what they need. This reduces the size of the warehouse required and minimizes the chance of products going to waste. In simple terms, a lean warehouse is a green warehouse.

The Impact of Sustainable Packaging

We have all had that experience where we order a tiny item and it arrives in a massive box filled with plastic air pillows. It is frustrating, right? This is a classic example of inefficient logistics. Packaging is a huge part of the eco friendly logistics equation. It affects how much space a product takes up on a truck, how much it weighs, and what happens to it after the customer opens it.

The first goal of sustainable packaging is material reduction. This is often called “right-sizing.” By using a box that actually fits the product, you use less cardboard and you can fit more boxes on a single pallet. This directly reduces the number of trucks needed on the road. Lightweighting is another strategy. If you can make a bottle or a container thinner without losing its strength, you reduce the total weight of the shipment. This might seem small, but when you are shipping millions of units, those ounces add up to tons of fuel savings.

Then there is the material itself. We are seeing a big shift toward recyclable, biodegradable, or compostable materials. But even better than recycling is reuse. Returnable transport items, like plastic crates or metal containers that can be used hundreds of times, are becoming more common in B2B logistics. If you are curious about the latest innovations in this space, you can dive deeper into our resource on sustainable packaging solutions. It is one of the most visible ways a brand can show its commitment to the planet.

Standardization and Modularity

Here is something most people miss. If all boxes were designed to fit perfectly together like LEGO bricks, we would have almost zero wasted space on our pallets. This is the idea behind packaging standardization. When companies use modular sizes, they maximize every square inch of the shipping container. This means fewer containers, fewer ships, and a much smaller environmental footprint. It is a simple concept, but it requires a lot of coordination across the supply chain.

Reverse Logistics and the Circular Economy

In the old way of doing things, the supply chain was a straight line. You make something, you sell it, the customer uses it, and then it goes in the trash. Sustainable logistics is helping to change that line into a circle. This is what we call the circular economy. The idea is to keep materials and products in use for as long as possible. To do that, we need a system for things to move backward. This is called reverse logistics.

Reverse logistics handles everything that comes back from the consumer. This includes returns of unwanted items, but it also covers products that need to be repaired, refurbished, or recycled. If a company is good at reverse logistics, they can capture the value of those “old” products. Maybe they can fix them and sell them at a discount. Maybe they can harvest the parts. At the very least, they can make sure the materials are properly recycled rather than ending up in a hole in the ground.

This is a critical component of sustainable logistics because it requires a whole different kind of thinking. Traditional logistics is all about moving large quantities of the same thing to many locations. Reverse logistics is about picking up small quantities of different things from many locations and bringing them back to a central point. It is complex and can be expensive, but it is one important way to close the loop and reduce our reliance on raw materials. The United Nations Sustainable Development Goals highlight this move toward responsible consumption and production as a key priority.

Closed-Loop Supply Chains

A “closed-loop” system is the gold standard of sustainability. This is when a company designs a product with its eventual return in mind. Think of a printer manufacturer that provides a prepaid label for you to send back your old ink cartridges. They take those cartridges, clean them, refill them, and sell them again. Logistics is the engine that makes this possible. Without an efficient way to get those cartridges back, the whole system falls apart. This is why logistics experts are now sitting at the table when products are being designed. They need to figure out how to get the product back before it is even made.

Navigating the Challenges and Barriers

If sustainable logistics is so great, why isn’t everyone doing it perfectly yet? Let us be honest here. It is hard. There are real obstacles that make this transition difficult for many companies. If you are feeling overwhelmed by the prospect of changing your operations, you are in good company. Understanding these barriers is the first step toward overcoming them.

The most obvious hurdle is the upfront cost. Buying electric trucks or installing solar panels requires a lot of capital. Even if these things save money in the long run, the initial price tag can be scary. There is also the issue of infrastructure. You might want to buy 50 electric vans, but does your warehouse have the power capacity to charge them all at once? Are there enough charging stations on the routes your drivers take? In many parts of the world, the infrastructure just isn’t there yet. This is a classic “chicken and egg” problem that requires cooperation between businesses and governments.

Then there is the complexity. Most logistics networks have been built over decades. They are full of long term contracts, legacy IT systems, and established ways of doing things. Changing a route or switching a packaging material can have ripple effects that are hard to predict. There is also a lack of standardized data. It is often difficult to compare the emissions of one carrier against another because they might use different ways of measuring. This uncertainty can make it hard for managers to justify the “green” choice to their bosses.

Overcoming the Resistance

So how do we move forward? What we found is that the most successful companies start small. They run pilot programs. They test one electric van in one city. They switch the packaging for one product line. This allows them to gather data and prove the concept before scaling it up. They also collaborate. Sustainability is not a solo sport. Companies are working with their suppliers, their customers, and even their competitors to share assets and best practices. By working together, they can build the infrastructure and the standards that everyone needs.

Future Trends to Watch

The world of sustainable logistics is moving fast. Things that seemed like science fiction five years ago are now becoming reality. As we look ahead, there are a few key trends that are going to define the next decade of the industry. You will want to pay attention to these if you want to stay ahead of the curve.

- Digital Twins: Companies are creating virtual replicas of their entire logistics network. This allows them to run “what-if” scenarios to see how different changes will affect their carbon footprint and their costs without risking any real-world disruptions.

- Micro-fulfillment Centers: To solve the last-mile problem, we are seeing small warehouses pop up in the middle of cities. These are often automated and allow for deliveries to be made by foot, bike, or small EV, cutting down on urban congestion.

- AI-Driven Orchestration: We are moving beyond simple route planning. AI is now being used to coordinate entire global networks, predicting weather patterns, port delays, and demand spikes to keep everything moving as efficiently as possible.

- The Rise of Green Hydrogen: While batteries are widely seen as well suited for smaller vehicles and shorter routes, hydrogen is being explored as a promising option for long-haul shipping and heavy trucking. It has a higher gravimetric energy density than current battery technologies and can be refueled quickly.

These technologies are exciting, but they are just tools. The real change is the shift in mindset. We are moving from a world where we “take, make, and waste” to a world where we “reduce, reuse, and recycle.” Logistics is the glue that holds that new world together. It is an exciting time to be in this field because the work you do has a direct, measurable impact on the future of our planet.

Frequently Asked Questions

What is the difference between sustainable logistics and traditional logistics?

Traditional logistics focuses almost entirely on the “bottom line” of cost, speed, and reliability. It is about getting things from point A to point B as efficiently as possible for the business. Sustainable logistics takes that same goal but adds two more layers. It considers the environmental impact (emissions, waste) and the social impact (worker safety, community health). In short, it is about being efficient for the business, the planet, and the people all at once.

Is sustainable logistics more expensive for businesses?

This is a great question. In the short term, there can be higher costs for things like new technology or eco friendly materials. However, many sustainable practices actually save money right away. For example, route optimization reduces fuel costs, and right-sized packaging reduces shipping fees. Over the long term, sustainability can protect companies from rising fuel prices and expensive environmental regulations, often making it the more profitable choice.

How does sustainable logistics relate to the circular economy?

Logistics is the “how” of the circular economy. For a circular economy to work, products and materials need to move back and forth between consumers and producers. Sustainable logistics provides the systems, like reverse logistics and closed-loop supply chains, that make this possible. Without an efficient way to collect, transport, and process old products, the circle never closes.

What are some easy ways for a small business to start with sustainable logistics?

You don’t need a fleet of electric trucks to start. Small businesses can begin by auditing their packaging to see if they can use less material or switch to recyclable options. They can also work with carriers that participate in green freight programs. Another easy win is “consolidating” shipments so you are sending one full box instead of three half-empty ones. It is all about starting with what you can control.

Why is transparency important in sustainable logistics?

Transparency is everything because you can’t improve what you don’t measure. Customers and regulators want to see the data behind a company’s “green” claims. By being transparent about your carbon footprint and your supply chain practices, you build trust with your audience. It also allows you to identify the specific parts of your operation that need the most work, helping you spend your sustainability budget more effectively.

Summary of Key Takeaways

We have covered a lot of ground today. If you take nothing else away from this guide, remember these three things. First, sustainable logistics is a holistic approach that balances the environment, society, and the economy. It is not just about “being green,” it is about being smart. Second, transportation and warehousing are the two biggest areas where you can make an impact. Whether it is through mode shifting, better route planning, or energy-efficient buildings, the opportunities for improvement are massive. Third, the transition isn’t always easy, but it is necessary.

The good news is that you don’t have to do everything at once. Small, incremental changes in how you pack, ship, and manage your inventory can add up to a huge difference over time. The industry is changing, and the tools we have to make a difference are getting better every day. You are asking the right questions just by being here and learning about this. The next step is to look at your own operations and find that first “easy win.” Whether that is measuring your footprint or trying out a new packaging material, every step counts. You have got this, and we are here to help you along the way. Ready to start making your logistics more sustainable?