The Pick Pack Ship Process: Streamlining Order Fulfillment

Are you looking for the exact breakdown of the pick pack ship process? You have come to the right place. While general guides cover the basics of logistics, you need the specific details that actually help you speed up delivery and reduce errors. We are going to get straight into what works, what does not, and exactly what you should do to master this workflow. Let us get specific.

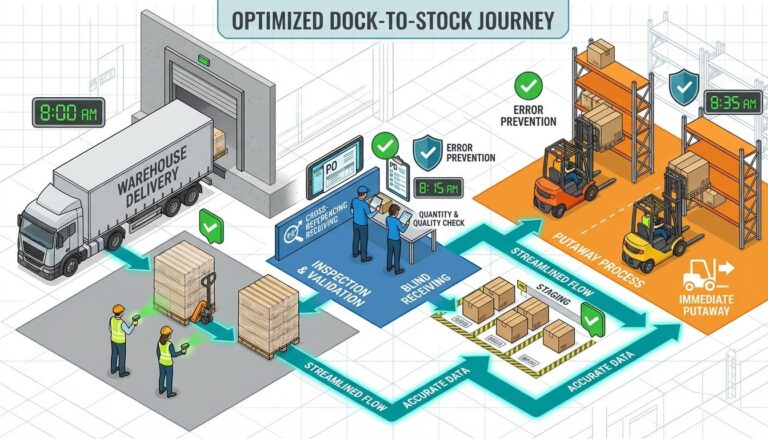

If you are reading this, you probably already know the basics of running a warehouse. You are looking for the specific answer to how these three steps connect to create a seamless fulfillment engine. This is the detailed breakdown you have been searching for. Before a single item can move toward a customer, it must first be brought into the building correctly. For a complete overview of how that initial stage works, check out our main guide on the warehouse receiving process. Once those goods are on the shelves, the real work of the pick pack ship process begins.

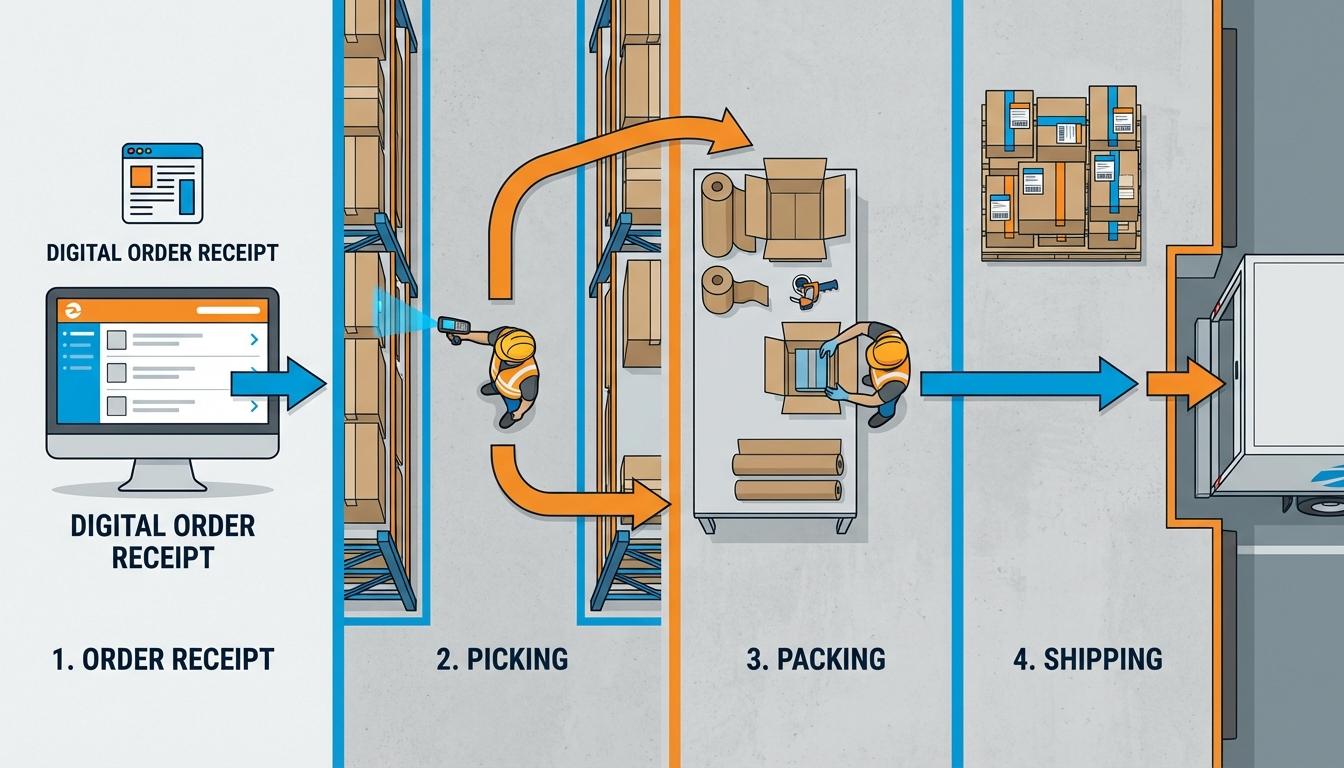

The Transition from Order Receipt to the Warehouse Floor

The pick pack ship process does not start when a worker grabs a box. It starts the millisecond a customer clicks the buy button. In a modern operation, your Warehouse Management System (WMS) or Order Management System (OMS) acts as the brain. This system receives the order and immediately checks inventory levels. It ensures you are not selling stock you do not have. This is the detail that changes everything for your customer service team. No one wants to send an out of stock email two days after an order was placed.

Once the order is verified, the system generates two critical pieces of paper or digital files. These are the pick list and the packing slip. The pick list tells your team what to grab and where it is located. The packing slip stays with the order to tell the customer what is inside. Many operations now use digital versions of these to reduce paper waste and improve speed. The real question is how you prioritize these orders. Your best move here is to queue orders based on shipping deadlines. If a customer paid for overnight shipping, that order should jump to the front of the picking line immediately.

Here is what that actually looks like in practice. Your system should automatically group orders to minimize travel time for your staff. If ten different customers all ordered the same SKU, your system should flag those for a single trip to that shelf. This is the first step in moving from a slow, manual process to a high-speed fulfillment machine.

Mastering the Picking Process: Speed and Accuracy

When it comes to picking, the goal is simple. You want the highest accuracy with the lowest travel time. In most warehouses, travel time accounts for 50 percent or more of a picker’s total shift. That is a lot of wasted movement. To fix this, you need a strategy that matches your order volume. Let us look at this closely.

Single Order vs. Batch Picking

Single order picking, also known as discrete picking, is where one person picks one order at a time. This is easy to learn but very inefficient for high volume. If you are just starting out, this works. However, once you hit a certain scale, batch picking is the superior choice. In batch picking, a worker picks items for multiple orders at once. This works best when you have many orders with the same SKUs. It cuts down on repetitive trips to the same bin. Your next step is to analyze your order data. If your customers frequently buy the same items, batch picking will save you hours every week.

Zone and Wave Picking

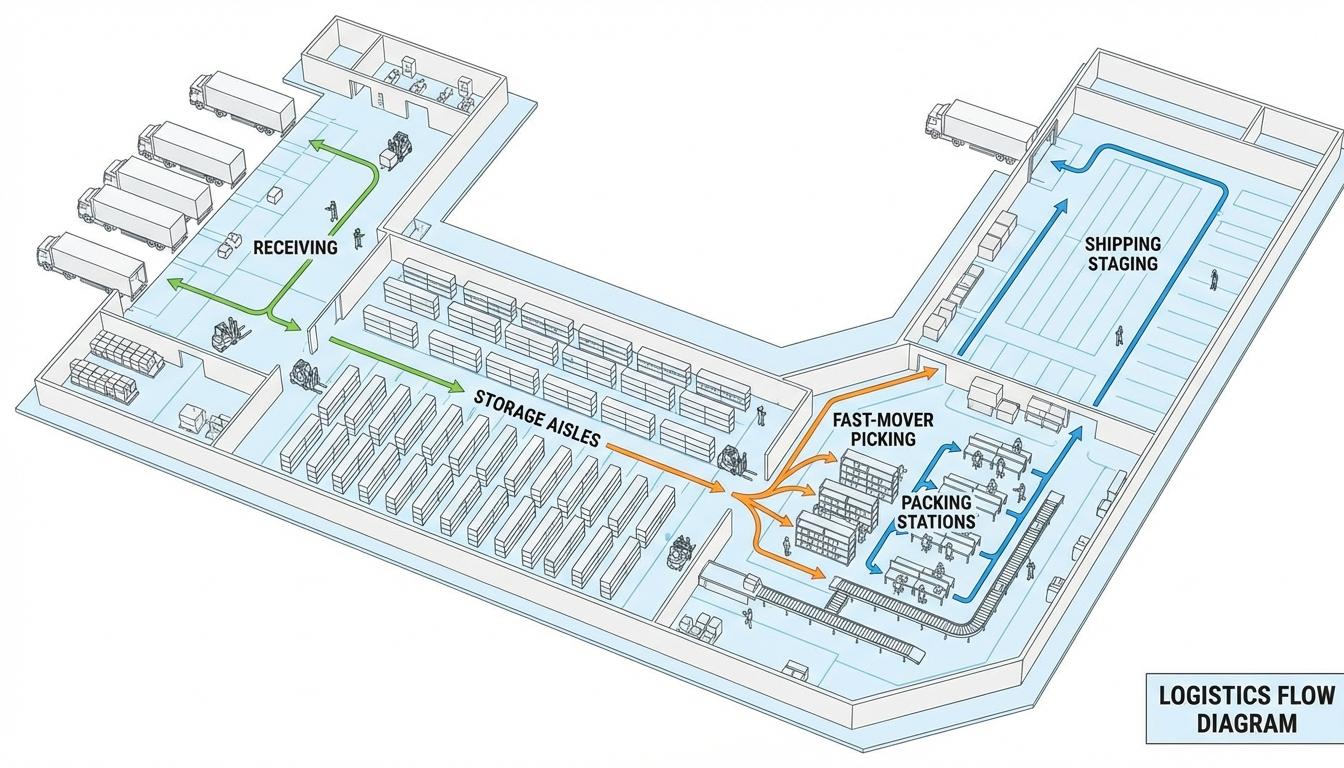

For larger warehouses, zone picking is often the answer. Think of this like an assembly line. Each picker is assigned to a specific area, or zone. They only pick items located in that zone. The order container moves from zone to zone until it is complete. This keeps workers specialized and reduces long walks across the building. Wave picking is slightly different. It aligns picking with shipping schedules. You might pick all orders going out via UPS in one wave, then all FedEx orders in the next. This ensures you never miss a carrier pickup deadline.

To make any of these methods work, you must have an organized warehouse. If your fast moving items are hidden in the back, your picking speed will suffer. You should implement a strategy where high velocity items are placed in the most accessible spots. For a deeper look at how to arrange your inventory for maximum efficiency, see our warehouse slotting guide. The practical takeaway is that your layout dictates your speed.

The Packing Operation: Protection and Verification

Packing is more than just putting items in a box. It is the final quality control check before the product leaves your sight. This is where most errors are caught, or unfortunately, where they are sent out to the customer. We have seen this stage get rushed constantly, which leads to high return rates and damaged goods. Let us get into the details of a professional packing station.

Every packing station should start with a verification scan. The packer scans the item barcode and the packing slip barcode. If they do not match, the system should throw a red flag. This simple step can virtually eliminate wrong-item shipments. Once verified, the packer chooses the container. Here is the thing most people miss. Using a box that is too large does not just waste money on packing peanuts. It costs you more in shipping. Carriers use dimensional weight (DIM weight) to charge based on the size of the box, not just the weight. According to FedEx packaging guidelines, choosing the right sized container and using proper cushioning is essential for both cost control and damage prevention.

The action item here is simple. Provide your packers with a variety of box sizes and mailers. Train them to select the smallest container that safely fits the order. Use sustainable void fill, like recycled paper or air pillows, to prevent shifting. This protects your brand reputation. A customer who opens a box to find a broken item is a customer you might lose forever. This is one of those areas where getting it right makes a real difference.

The Shipping Workflow: The Final Hand-off

The shipping workflow is the final leg of the internal process. This is where the packed box becomes a labeled parcel ready for the carrier. The key difference between a good shipping process and a great one is automation. If your team is manually typing addresses into a carrier website, you are losing money every single minute.

Modern shipping software integrates directly with your WMS. As soon as the packer finishes, the software should automatically weigh the package and calculate the best rate. This is called rate shopping. It compares prices between UPS, USPS, FedEx, and regional carriers in real time. Your best move here is to set rules within your software. For example, any package under one pound should automatically go via USPS Ground Advantage. This removes the guesswork for your staff and ensures you always get the best price.

Once the label is printed and applied, the order is staged for pickup. Most warehouses use a staging area near the loading dock. You should separate these by carrier to make the driver’s job easier. When the carrier arrives, they scan a manifest. This single scan accepts all the packages into their system at once. This triggers an automated email to the customer with their tracking number. The real goal is transparency. Customers want to know exactly where their package is the moment it leaves your dock.

Optimizing the Physical Flow of Goods

Even the best software cannot fix a warehouse that is physically disorganized. The pick pack ship process relies on a logical flow. Items should move in a straight line or a U-shape from the receiving dock to the shipping dock. If your pickers are constantly crossing paths with your packers, you have a bottleneck. Quick reality check here. When was the last time you walked your warehouse floor and looked for traffic jams?

Your packing stations should be located immediately adjacent to the picking zones. This reduces the distance the “picked” goods have to travel. Similarly, the shipping scale and label printers should be right at the packing station or a few steps away. Every step you save adds up. In a high volume environment, saving five steps per order can save miles of walking over a month. To truly optimize this flow, you might need to rethink your entire floor plan. You can find detailed strategies for this in our guide on warehouse layout optimization. The goal is a frictionless movement of goods from point A to point B.

Quick Reference: Pick Pack Ship at a Glance

- Picking: Use batch or zone picking to reduce travel time and use barcode scanners to ensure SKU accuracy.

- Verification: Always scan the item against the packing slip at the packing station to catch mis-picks.

- Packing: Use right-sized boxes to avoid unnecessary dimensional weight charges and reduce waste.

- Void Fill: Use enough protection to prevent movement, but do not overstuff the box.

- Shipping Software: Automate label printing and rate shopping to find the cheapest, fastest carrier.

- Staging: Organize outbound parcels by carrier near the dock to speed up the hand-off.

- Tracking: Ensure your system automatically pushes tracking data to the customer immediately.

Common Questions About the Pick Pack Ship Process

What is the most common cause of errors in pick pack ship?

The answer is almost always manual data entry or lack of barcode scanning. When humans have to read numbers and type them into a system, mistakes happen. Using handheld scanners at both the picking and packing stages is the most effective way to eliminate these errors and reach near 100 percent accuracy.

Should I use a 3PL for my pick and pack operations?

It depends on your scale and your expertise. If you find that fulfillment is taking up all your time and preventing you from growing the business, a third-party logistics (3PL) provider is a great move. They specialize in this exact process and can often get better shipping rates than you can on your own. However, you will lose some control over the personal touch of your packaging.

How do I measure the success of my fulfillment process?

You should track three main Key Performance Indicators (KPIs). First is the order accuracy rate. Second is the cost per order shipped. Third is the cycle time, which is how long it takes from order receipt to carrier pickup. If these numbers are improving month over month, your process is healthy.

What is the difference between pick and pack and order fulfillment?

Pick and pack refers specifically to the physical warehouse steps of selecting and boxing items. Order fulfillment is a much broader term. It includes everything from the moment the customer places the order to the final delivery and even the management of any returns. Pick and pack is the heart of fulfillment, but not the whole thing.

The pick pack ship process is a cycle that rewards attention to detail. Every small improvement you make in picking speed or packing accuracy has a massive ripple effect. When your warehouse runs like a well-oiled machine, your customers get their orders faster and your costs go down. Ready for the specifics of your next move? Start by auditing your current packing station. Is it cluttered? Is the tape dispenser in a weird spot? Fix those small physical hurdles first.

Your next step is to look at your data and see where the bottlenecks are. Are your pickers waiting for packers to catch up? Or are your packers waiting for labels to print? Identify that one point of friction and solve it this week. This is exactly how you build a world class fulfillment operation. If you ever feel overwhelmed by the complexity of the warehouse, remember that it all comes back to these three core steps done with excellence. You have the tools and the information. Now it is time to get to work.