Warehouse Slotting: Strategies for Faster Picking

Are your pickers spending more time walking through aisles than actually grabbing items? If the answer is yes, you are likely dealing with a layout that has not been optimized for your current inventory flow. This is where warehouse slotting comes into play. It is the strategic science of assigning every SKU to its most efficient storage location to cut down on travel time and boost productivity. While it sounds straightforward, the execution is where most operations either win big or lose thousands in labor costs every month.

You might already know that putting fast movers near the front is a good idea. That is basic common sense. But we are here to go much deeper than the basics. This is the detailed breakdown of how you turn a chaotic floor into a high-speed fulfillment machine. We are going to look at specific data points, the nuances of SKU slotting, and how to maintain this efficiency as your business changes. Let us get specific about how you can transform your operations.

The Core Mechanics of Warehouse Slotting

At its heart, warehouse slotting is about reducing “touches” and travel distance. In a typical manual picking environment, travel time often accounts for 40 to 60 percent of a picker’s total labor time. That is a massive amount of paid time spent simply moving from point A to point B. By implementing a rigorous slotting strategy, you are essentially shortening those paths. For a complete overview of how this fits into your broader fulfillment strategy, check out our main guide on the pick pack ship process.

The process involves two main levels: macro and micro slotting. Macro slotting looks at the big picture. It determines which zones should hold pallets versus which should hold individual bins. Micro slotting is the granular work. It is the specific slot assignment of a SKU to a specific bin or shelf level within those zones. When you get both levels right, your warehouse operates with a level of fluidity that feels effortless to the staff on the floor.

Why does this matter so much right now? Because space is expensive. Efficient slotting maximizes your “cube utilization.” This means you are using every inch of available space, from the floor to the rafters. Good slotting can often delay or even eliminate the need for a costly facility expansion by making your current footprint work harder for you. It is about working smarter, not just bigger.

Velocity Based Slotting: The ABC Method

The most common and effective way to start is through velocity based slotting. This approach categorizes your inventory based on pick frequency rather than just how many units you sell. A SKU that sells 1,000 units once a month is actually a “slow mover” compared to an item that sells one unit 1,000 times a month. The latter requires 1,000 trips to the shelf, making it a high-velocity item.

Here is the specific answer to how you should categorize these items using the ABC method:

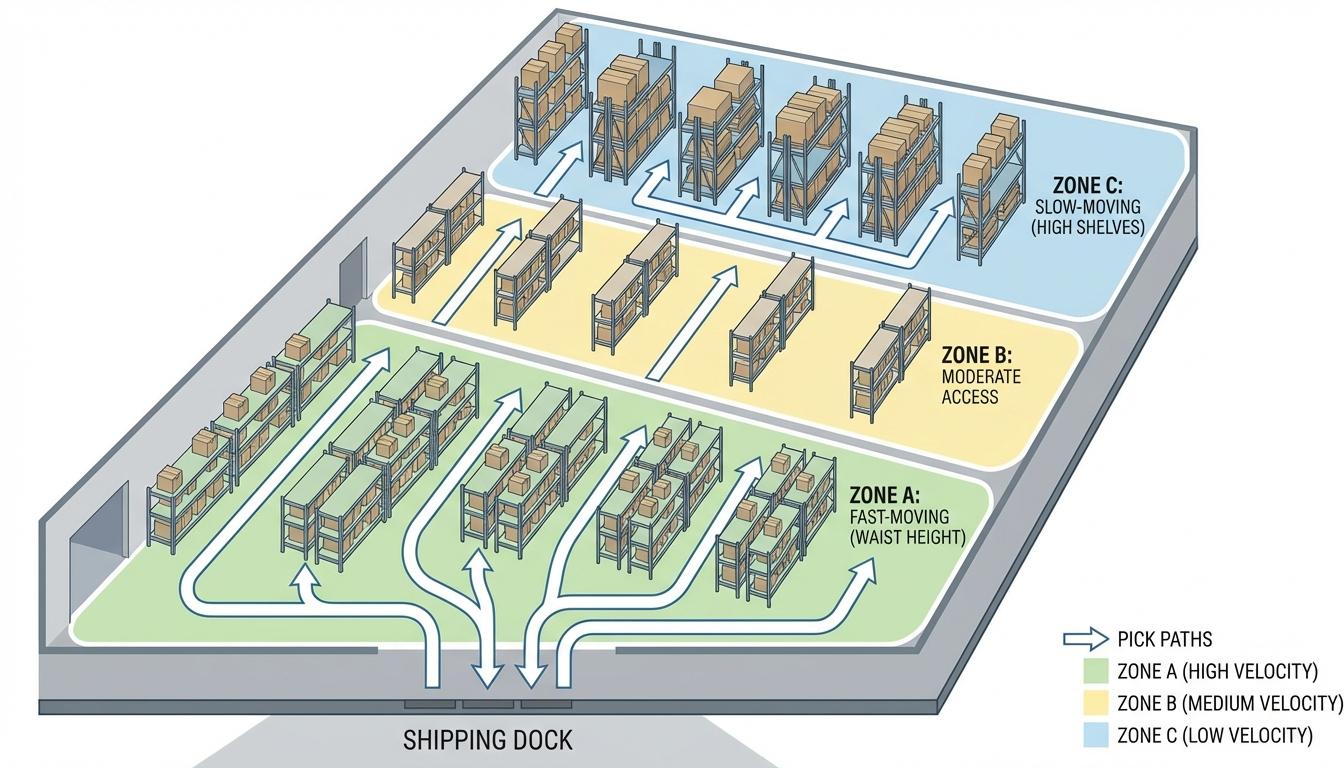

- A-Items: These are your rockstars. They represent a small percentage of your SKUs but a huge majority of your picks. These belong in “prime real estate” near the shipping docks and at waist-to-shoulder height to minimize reaching or bending.

- B-Items: These move at a moderate pace. They should be stored in accessible areas but can be placed slightly further away than your A-items or on shelves just above or below the ergonomic “golden zone.”

- C-Items: These are your slow movers. Since they are rarely touched, they can be stored in the back of the warehouse, on high shelves that require a ladder or lift, or in deep storage areas.

The practical takeaway is that your pickers should spend 80 percent of their time in 20 percent of your warehouse space. If your A-items are scattered across the entire facility, you are literally throwing money away on every single shift. Your best move here is to run a velocity report for the last 90 days and see where your “A” picks are currently located.

Optimizing Product Placement for Safety and Speed

When it comes to product placement warehouse strategies, you cannot ignore the physical reality of the items. Velocity is important, but weight and size are the hard constraints. If you place your heaviest fast-movers on a top shelf, you are creating a massive safety hazard and slowing down the picking process. Ergonomics should always be a primary factor in your slotting rules.

Let us look at this closely. Heavy items should always be slotted at “knee-to-waist” height. This allows pickers to use their legs and core to lift, rather than straining their backs or shoulders. Extremely light items, even if they move quickly, are better suited for higher shelves where they can be grabbed without significant physical strain. This focus on ergonomics does more than just prevent injuries. It keeps pickers from getting fatigued, which maintains a consistent pick rate throughout a ten-hour shift.

Another layer of pick location optimization involves “order affinity.” This is the practice of storing items together that are frequently bought together. Think of it like a grocery store putting chips right next to the salsa. If your data shows that customers who buy a specific camera always buy a specific memory card, those two SKUs should be slotted next to each other. This turns two separate trips into one single stop, effectively doubling your picking efficiency for those orders.

For more details on how to set up your facility for success before the items even hit the shelves, you might want to explore our insights on warehouse layout optimization.

The Technical Side: SKU Slotting and Data Inputs

You cannot guess your way to a perfectly slotted warehouse. It is a data-driven discipline. To perform effective SKU slotting, you need a “clean” item master file. If your system thinks a box is 10 inches wide but it is actually 12, your slotting plan will fail the moment you try to put the product away. Accuracy at the start of the process is the detail that changes everything.

Here is the step-by-step breakdown of the data you need to collect:

- Physical Dimensions: Length, width, height, and weight for every SKU, including the packaging.

- Historical Order Data: At least 3-6 months of pick history to identify trends and seasonal spikes.

- Storage Medium: What type of racking or shelving is available? Is it pallet rack, carton flow, or static shelving?

- Handling Requirements: Does the item need temperature control? Is it a hazardous material? Is it fragile?

Once you have this data, you can begin the slotting optimization process. Many modern Warehouse Management Systems (WMS) have built-in modules that can do this for you. They use algorithms to compare your SKU data against your available bin locations to suggest the most efficient map. If you are doing this manually, the real question is whether you have the time to keep up with it. Manual slotting is often a one-time project, but real optimization is a continuous cycle.

The implementation phase is where things get tricky. You cannot shut down your warehouse for three days to move every item. Instead, we recommend a “wave” approach. Start with your top 100 A-items. Move them into their new, optimal slots over a weekend or during a slow shift. Measure the impact, then move on to the next group of SKUs. This minimizes disruption while providing immediate improvements in pick speed.

Fixed vs. Random Slotting: Which Works Best?

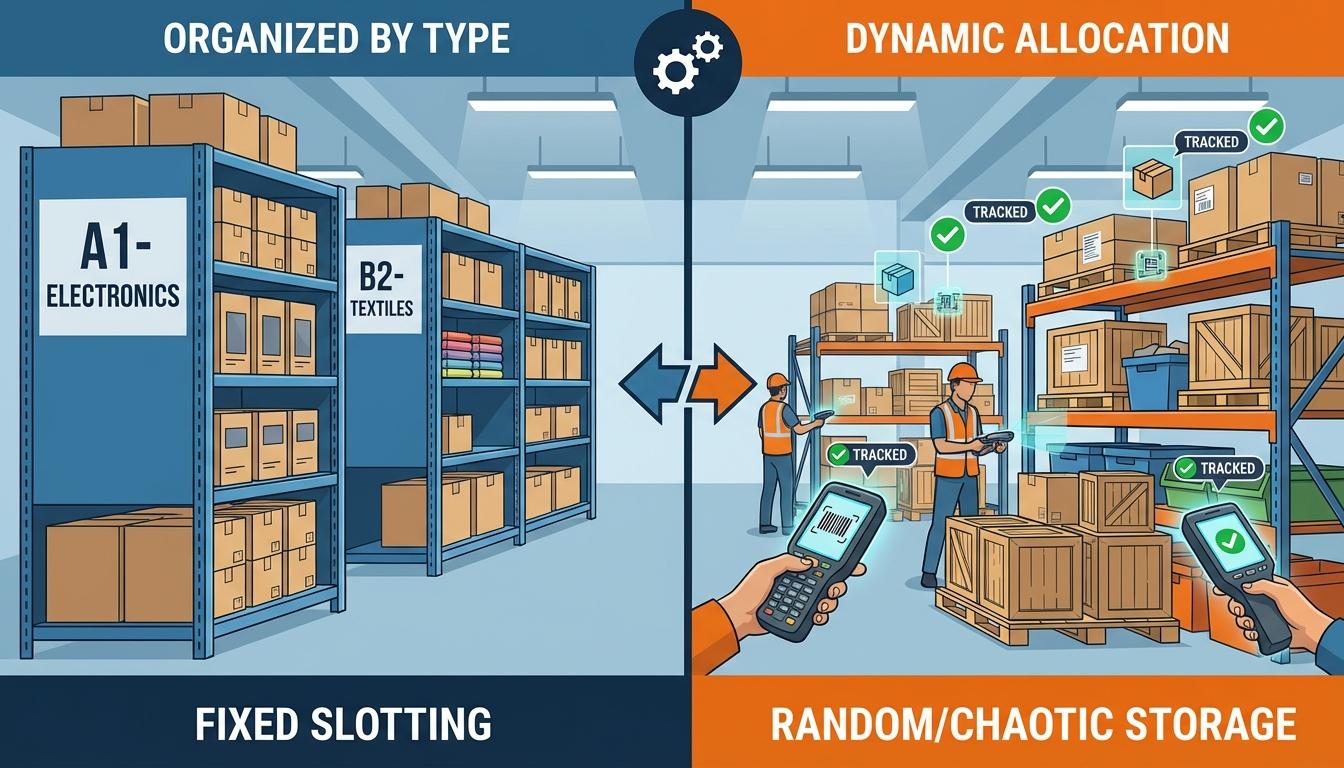

There is a reason this specific aspect confuses people. There is no one-size-fits-all answer. The choice between fixed and random slotting depends entirely on your business model and the technology you use. Let us get into the details of both so you can decide which approach works best for your specific case.

Fixed Slotting assigns a permanent, dedicated home to every SKU. This is great for small operations or facilities with very stable inventory. Pickers eventually learn the warehouse by heart, which can lead to very fast picking. However, it is incredibly inefficient for space. If a fixed slot is empty because you are out of stock, that space remains empty and unusable for anything else. It is a “rigid” system that struggles with growth.

Random Slotting (often called chaotic storage) is the strategy famously used by Amazon. A SKU is placed in any available opening that fits its dimensions. The system tracks the location, and the WMS tells the picker exactly where to go. This maximizes every square inch of space and allows for much higher inventory density. The downside? You are 100 percent dependent on your technology. If your WMS goes down or your data is wrong, you will never find your product.

Most high-performing warehouses use a hybrid approach. They use fixed slots for their high-velocity A-items to ensure they are always in the most ergonomic positions. For B and C items, they use random slotting to fill in the gaps and maximize space. This gives you the speed of dedicated locations where it matters most, combined with the space efficiency of random storage everywhere else.

Quick Reference: Warehouse Slotting at a Glance

- Primary Goal: Minimize travel time and maximize space utilization.

- Key Metric: Picks per hour and travel distance per order.

- The Golden Rule: Keep A-items in the ergonomic “golden zone” near shipping.

- Data Needs: Accurate SKU dimensions, weight, and pick velocity.

- Review Frequency: Quarterly for most; monthly for highly seasonal businesses.

- Safety First: Heavy items low, light items high, fast movers at waist height.

The Role of Technology in Modern Slotting

Let us cut to what matters: if you have more than 500 SKUs, managing slotting with a spreadsheet is a recipe for burnout. Modern technology has turned slotting from a reactive chore into a proactive strategy. Advanced software can now run “what-if” scenarios. For example, it can show you exactly how much time you would save if you moved your seasonal winter gear to the front of the warehouse in October.

Automation also changes the game. Systems like Vertical Lift Modules (VLMs) or AutoStore essentially handle the slotting for you. They bring the items to the picker, eliminating travel time entirely. But even in these automated systems, the software still has to decide which bin goes where. It will keep the fast-moving bins at the top of the stack for faster retrieval. This proves that no matter how much tech you throw at a warehouse, the principles of velocity and accessibility remain the same.

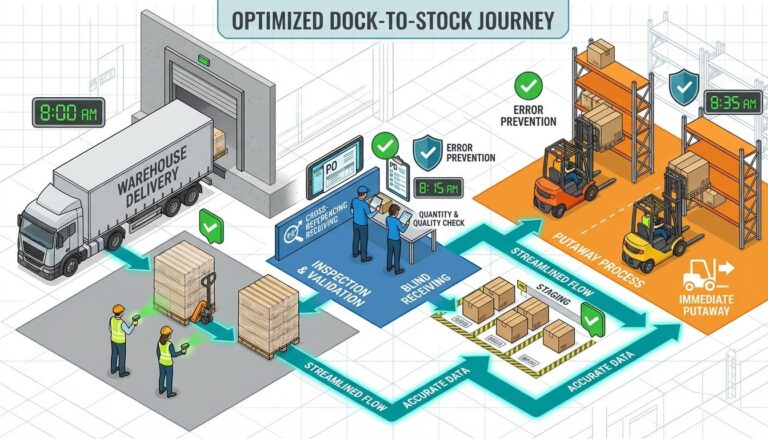

Your next step is to look at your WMS and see if you are actually using the slotting tools you are already paying for. Many operations have powerful optimization features that sit dormant because the initial setup seemed too daunting. It is worth the effort. The labor savings from a well-slotted warehouse usually pay for the software investment in less than a year. To see how these items get to their slots in the first place, read about the warehouse receiving process.

Common Questions About Warehouse Slotting

How often should we re-slot our inventory?

The answer is that it depends on your product lifecycle. At a minimum, you should do a full review annually. However, if you have high seasonality or frequently introduce new products, quarterly reviews are necessary. Some high-velocity e-commerce sites even perform “micro-reslotting” weekly to account for changing trends.

Can we slot by product family instead of velocity?

Yes, and here is why: sometimes “affinity” is more important than pure velocity. If you sell car parts, it makes sense to keep all the components for a specific engine type together, even if some of those components are slower movers. This reduces the picker’s mental load and can prevent errors, which is often worth the slight increase in travel distance.

What is the biggest mistake people make in slotting?

The most common pitfall is ignoring replenishment. If you create a tiny pick face for an A-item to keep travel short, but that location needs to be refilled every hour, you have simply moved the labor cost from the picker to the replenishment driver. You must balance pick efficiency with the “behind-the-scenes” work of keeping those slots full.

Does slotting help with picking accuracy?

Absolutely. When items are logically grouped and stored in well-labeled, organized slots, the chances of a picker grabbing the wrong item drop significantly. Clear slotting reduces “search time,” which is a major contributor to both slow picking and mental fatigue that leads to errors. According to industry studies published by Material Handling & Logistics, optimized slotting can improve accuracy by up to 20 percent.

Final Thoughts on Slotting Strategy

Warehouse slotting is not a one-time project you can “set and forget.” It is a living part of your operation that needs to evolve as your customers’ habits change. The core objective remains the same: put the right product in the right place to make life easier for your pickers and more profitable for your business. By focusing on velocity, ergonomics, and data accuracy, you can reclaim those lost hours of travel time and significantly increase your throughput.

The practical takeaway is simple. Start with your data. Run your velocity reports, verify your item dimensions, and identify your “A” picks. Even small changes, like moving your top ten items to the front of the line, will show immediate results. As you get more comfortable with the process, you can move toward more complex strategies like affinity grouping and random slotting. If you found this specific breakdown helpful, you might want to learn more about the broader context of fulfillment operations. Now is the time to get your team together and start mapping out a more efficient future for your floor.