3PL Contract Negotiation: Key Terms You Must Address

Looking for the exact breakdown of 3PL contract negotiation? You have come to the right place. While general guides cover the basics of logistics, you need the specific details that actually help you protect your margins and service levels. We are going to get straight into what works, what does not, and exactly what you should do during the negotiation process. Let us get specific.

Negotiating a contract with a third-party logistics provider is not just about getting the lowest price. It is about building a framework that allows your business to scale without service failures. You are looking for the detailed breakdown, not the surface level stuff. This guide covers the critical 3PL agreement terms and negotiation strategies that ensure your partnership is productive from day one. If you are still in the early stages of your search, our how to choose 3PL guide provides the broader context you need to find the right partner before you even sit down at the table.

Preparation Is Your Only Leverage

You cannot walk into a negotiation room without your data. This is one of those areas where getting it right makes a real difference. If you do not know your numbers, the 3PL will define the terms for you. Here is the specific answer to what you need to gather before the first meeting.

Start by assessing your logistics needs with extreme precision. We are talking about shipment volumes, order frequency, storage requirements, and shipping projections for the next twelve to twenty four months. You also need to gather data on your current costs. This includes everything from packaging materials to last-mile delivery fees. When you have these numbers, you can benchmark market rates to strengthen your position. This allows you to walk into a logistics contract discussion with a clear objective.

Your next step is to define your non-negotiables. Are you looking for cost reduction above all else? Or is scalability your primary goal? For many of our readers, faster delivery and improved service levels are the real priorities. Know your “must-haves” versus your “nice-to-haves” before the conversation starts. This preparation ensures you are leading the negotiation rather than reacting to the provider’s standard template.

The action item here is simple. Create a data sheet that includes your average daily order volume, peak season multipliers, and current return rates. Having this ready shows the provider that you are a sophisticated partner. It also prevents them from overcharging you based on vague assumptions about your business complexity.

Strategic 3PL Pricing Negotiation

Let us get into the details of pricing. Most people focus on the base rate per order and stop there. That is a mistake. The real question is what your Total Cost of Ownership (TCO) looks like. When it comes to 3PL pricing negotiation, the base rate is often just the tip of the iceberg.

We recommend prioritizing TCO over upfront pricing. This means looking at transportation costs, warehousing fees, handling charges, and surcharges. Watch out for hidden costs like “account management fees” or “technology integration fees” that can inflate your monthly bill. A low pick-and-pack fee does not matter if the storage rates are double the market average. Your best move here is to request a fully transparent pricing structure where per-unit costs decrease as your volume increases.

- Leverage Volume: Use your projected growth to negotiate tiered discounts. If you hit 5,000 orders a month, your rate should be lower than when you were at 1,000.

- Request Transparency: Ask for a detailed breakdown of all fuel surcharges and accessorial fees.

- Avoid Long-term Lock-ins: Try to negotiate a trial period of three to six months. This allows you to test the fit before committing to a multi-year deal.

- Benchmark Rates: Use industry reports to ensure the storage costs per pallet or square foot are competitive for that specific geographic region.

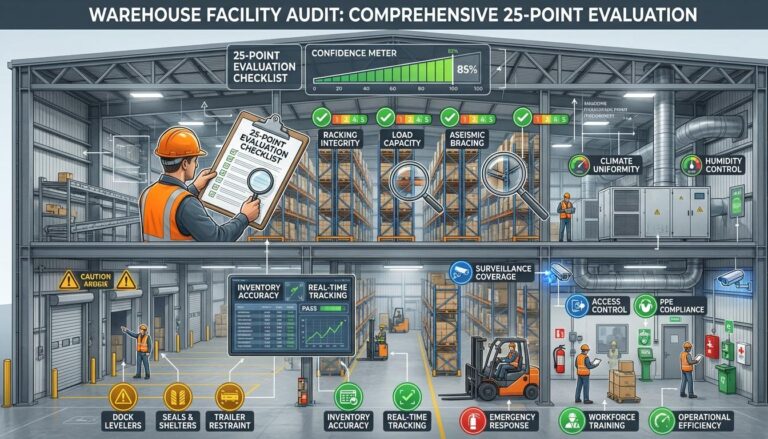

So what does this mean for you? It means you should never sign a contract that does not have a clear path for price adjustments. Markets shift and your business will change. You need the flexibility to adjust your warehousing contract terms as your SKU count or order profile evolves. For a deeper look at the operational side of these facilities, you can use our 3PL warehouse evaluation checklist to see if their physical capabilities match their pricing.

Mastering 3PL SLA Negotiation

Detailed Service Level Agreements (SLAs) are the teeth of your contract. Without them, you have no way to hold your provider accountable when things go wrong. This is the detail that changes everything. 3PL SLA negotiation is about defining exactly what “good service” looks like in measurable numbers.

Key metrics you must address include order fulfillment cut-off times and error rates. For example, if an order is placed by 2:00 PM, it must ship the same day. You should also define an inventory shrink allowance. Most standard contracts allow for 1% to 2% of inventory to simply disappear. We suggest negotiating this down as low as possible, especially if you sell high-value goods. According to legal experts at Reed Smith, written SLAs should always include governance structures and clear escalation procedures for dispute resolution.

The practical takeaway is to tie payments to these metrics. Implement performance-based agreements that include incentives for exceeding targets and penalties for falling short. If the 3PL misses their shipping window three days in a row, you should receive a credit. This aligns their financial success with your customer’s satisfaction. It turns a vendor relationship into a true partnership where both parties have skin in the game.

Here is how to apply this. Specify exactly how returns will be handled. Will they be processed within 24 hours? Who decides if an item is “refurbished” or “scrap”? Getting these details in writing prevents thousands of dollars in lost inventory and disgruntled customers later on.

Essential Clauses and Risk Mitigation

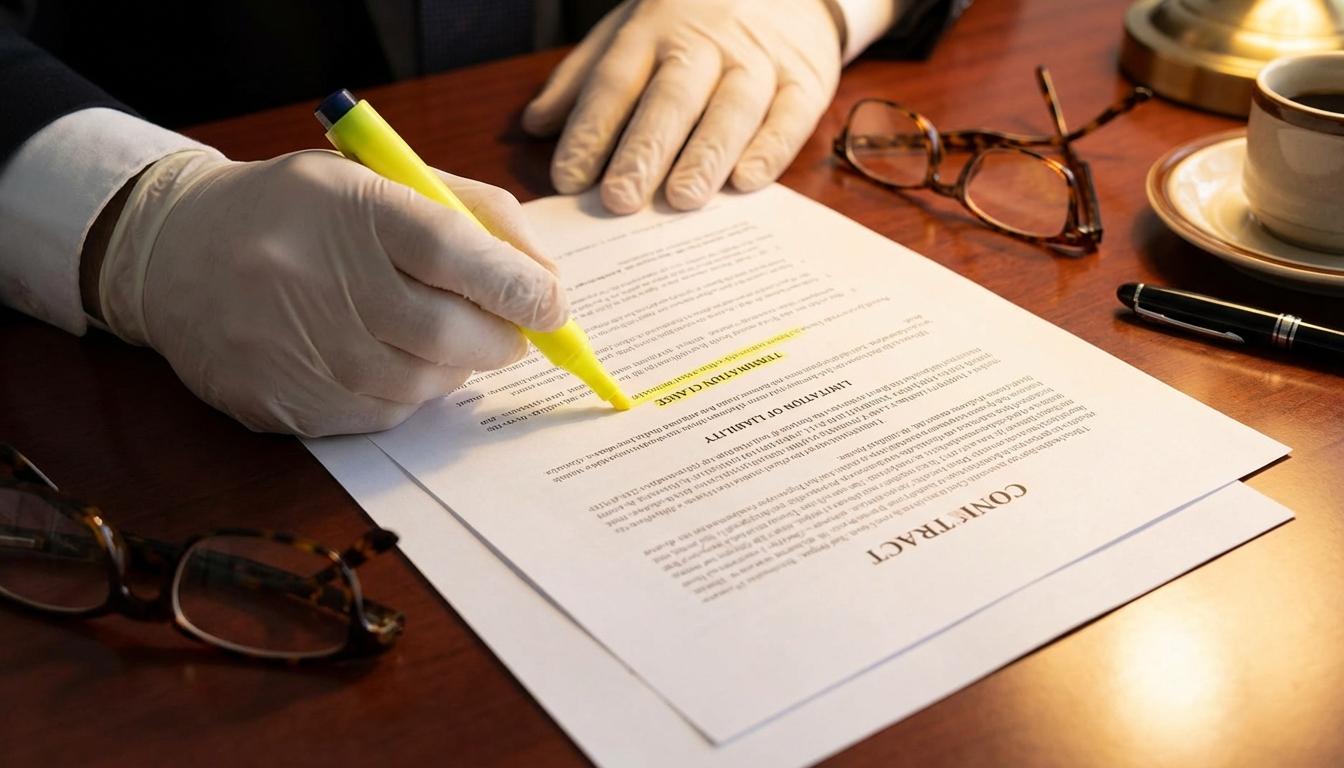

Now for the part you actually came here for. The clauses that protect your business during a “worst-case scenario.” Most 3PL agreement terms are written to protect the provider. You need to ensure the language is balanced. This is one of those areas where pragmatism beats aggression every time.

First, look at the scope of services. It needs to be incredibly specific. Does it include international shipping? Does it cover kitting or special packaging? If it is not in the contract, it is an extra charge. Second, address governance. We recommend establishing monthly senior management calls to review performance metrics and discuss upcoming volume shifts. This keeps the relationship proactive rather than reactive.

Risk mitigation is another huge factor. Research from Kearney emphasizes the importance of cross-functional risk assessments for long-term deals. You need clear definitions of what constitutes a “material breach.” If the 3PL loses their lease or has a massive labor strike, you need an exit clause that allows you to move your inventory without heavy penalties.

Here is what that actually looks like in practice:

- Termination for Convenience: Negotiate the right to end the contract with 60 or 90 days’ notice for any reason.

- Liability Caps: Ensure the provider’s liability for lost or damaged goods is not capped at an unreasonably low amount.

- Data Ownership: Explicitly state that all customer and inventory data belongs to you, not the 3PL.

- Business Continuity: Ask for their disaster recovery plan to be referenced in the contract.

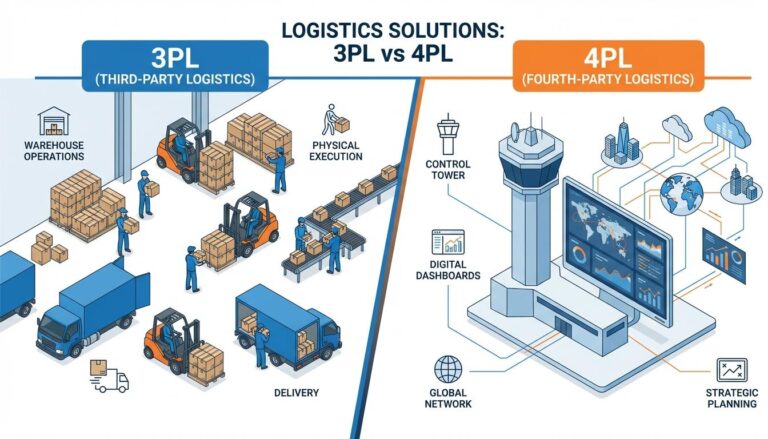

Quick reality check here. If a provider refuses to negotiate on basic liability or termination clauses, that is a major red flag. It might be time to reconsider the partnership entirely. Depending on your needs, you might even want to look into the differences between 3PL and 4PL models to see if a more managed solution fits your risk profile better.

Quick Reference: 3PL Contract Negotiation at a Glance

- Primary Focus: Total Cost of Ownership (TCO) rather than just unit rates.

- Key Metric: Order fulfillment cut-off times and accuracy percentages.

- Risk Protection: Negotiate inventory shrink allowances below 1% where possible.

- Scalability: Include tiered pricing that rewards higher shipment volumes.

- Accountability: Tie SLA performance to financial credits and bonuses.

- Exit Strategy: Ensure clear termination clauses and data ownership rights.

Common Questions About 3PL Contract Negotiation

What are the most important clauses in a 3PL contract?

The answer is a combination of pricing transparency, detailed SLAs, and termination rights. You must define exactly how fees are calculated and what happens if service levels are not met. Without clear governance and exit clauses, you can find yourself trapped in a failing partnership with no recourse.

How do you negotiate better pricing with a 3PL provider?

Your best move here is to leverage your data. Benchmark current market rates and present your long-term growth projections. Providers are often willing to lower upfront costs if they see a path toward high-volume, long-term business. Always ask for tiered pricing that scales with your success.

Why are SLAs so critical in 3PL agreement terms?

SLAs provide the objective standard for performance. They remove the “he-said, she-said” from the relationship. By defining metrics like order accuracy and inventory shrink, you create a baseline for accountability that protects your brand’s reputation with your customers.

What should I look for in a 3PL service agreement regarding flexibility?

The short version is that you need provisions for volume changes. Your contract should allow for seasonal spikes and unexpected dips without massive financial penalties. Look for review points in multi-year contracts that allow you to adjust terms as market conditions or your business model changes.

Moving Forward with Your Negotiation

Now you have the specific answer you came for. The key point? A successful 3PL contract negotiation is built on data, clear SLAs, and mutual accountability. Do not settle for a one-sided agreement that leaves your business vulnerable to hidden costs or poor performance. Focus on the Total Cost of Ownership and ensure you have the flexibility to grow.

For the bigger picture on managing your supply chain effectively, our complete guide on choosing a 3PL covers everything else you need to know about the selection process. Your next step is to pull your last six months of shipping data and draft your list of non-negotiable SLAs. Once you have that in hand, you are ready to secure a contract that actually supports your business goals.