The Complete Guide to Choosing the Right 3PL Partner

Are you feeling the growing pains of a business that is finally taking off? Maybe your living room is overflowing with boxes, or your current warehouse team is struggling to keep up with the holiday rush. If you have ever felt like you are spending more time taping boxes than growing your brand, you are likely looking for a solution. The answer is often a third party logistics provider, but knowing how to choose a 3PL that actually fits your business is where things get tricky. It is one of the biggest decisions you will make for your company, so we want to make sure you get it right.

We get it. The world of logistics is full of jargon, complex pricing sheets, and promises that sound a little too good to be true. You are looking for a partner who will care for your customers as much as you do, not just a vendor who sees you as a number on a spreadsheet. In this guide, we are going to walk through everything from the basic definitions to the nitty-gritty details of contract negotiations. Our goal is to turn this overwhelming process into a clear, manageable roadmap for your success.

What we found is that the best partnerships are built on transparency and shared goals. We are going to cover how to audit your own needs, what specific technology you should look for, and how to spot red flags before you sign a contract. Whether you are moving your first pallet or your fifty-thousandth, this guide will help you find a partner that helps you scale. Let us break this down together and find the path that works for you.

What is a 3PL and Why It Matters for Your Growth

Before we jump into the selection process, we should establish exactly what we are talking about. A 3PL, or third party logistics provider, is an external company that manages your supply chain functions. This can include anything from storing your products in a warehouse to picking, packing, and shipping them to your customers. Some 3PLs even handle returns, customs brokerage, and light assembly or kitting.

Why does this matter so much? Here is the thing. Most businesses start by doing everything themselves. But as you grow, logistics becomes a massive weight. By hiring a 3PL, you are essentially converting your fixed costs, like warehouse rent and staff salaries, into variable costs. You only pay for what you use. This gives you the freedom to focus on marketing, product development, and customer service while the experts handle the heavy lifting.

The Main Services You Will Encounter

Most 3PLs offer a core set of services that keep your business running smoothly. The most common is warehousing and distribution. This means they store your inventory in their facilities and manage the flow of goods. They also handle order fulfillment, which is the process of receiving an order from your website, picking the items from the shelf, and packing them securely for shipment.

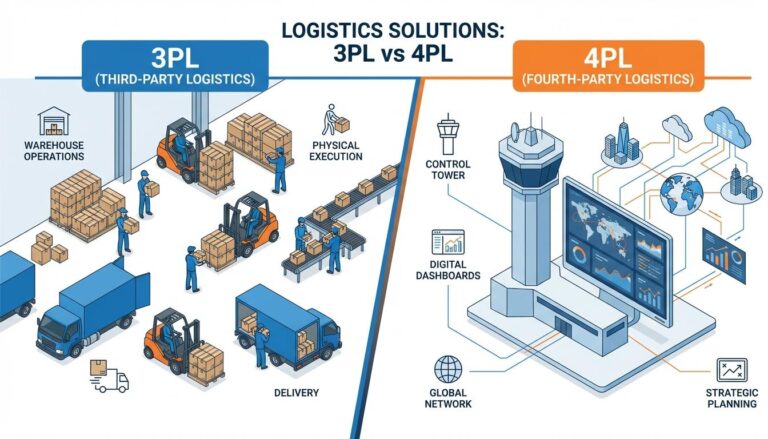

Beyond the basics, many providers offer transportation management. They use their relationships with carriers like FedEx, UPS, or LTL freight companies to get you better rates than you could get on your own. You might also find providers who offer value added services. This includes things like kitting, where multiple products are bundled into one package, or specialized labeling for retail compliance. If you are debating between different levels of support, you might want to learn about the 3PL vs 4PL differences to see which model matches your complexity.

The Strategic Advantage of Outsourcing

What this actually means for you is speed and scalability. Imagine your business doubles in size overnight because a product went viral. If you are managing your own warehouse, you are in trouble. If you have a 3PL, they can usually scale their labor and space to meet your demand. They have the technology and the systems in place to handle high volumes without breaking a sweat. This flexibility is a game changer for seasonal businesses that experience huge spikes in the winter but stay quiet in the summer.

Foundation: Clarify Your Business and Supply Chain Requirements

Here is where most people get confused. They start looking at 3PL websites before they actually know what they need. We suggest taking a step back. You cannot find the right partner if you do not have a clear picture of your own data. You need to be the expert on your own business before you ask someone else to manage it. This is the part most guides skip over, but it matters more than almost anything else.

Start by mapping out your current operations. How many orders are you shipping per day? What does your peak season look like compared to your slowest month? You should also look at your SKU count. If you have five products, your needs are very different from a company with five thousand. Document your average lines per order and the physical dimensions of your products. Are they small and light, or big and heavy? These details will dictate the kind of warehouse equipment and storage space your partner will need.

Defining Your Service Expectations

Now, you might be wondering about service levels. What do your customers expect? If you promise two day shipping, your 3PL needs to be able to meet that. Think about your cut off times. If an order comes in at 3 PM, does it ship that same day? You also need to consider returns. Reverse logistics is a massive part of modern e-commerce, and you need a partner who can process returns quickly so you can get items back into inventory or refund your customers without delay.

Do not forget about industry specific requirements. If you sell food or supplements, you might need a facility that is FDA registered or climate controlled. If you sell electronics, you need high security and perhaps serial number tracking. List these “must haves” clearly. This list becomes the backbone of your evaluation. It ensures you are comparing apples to apples when you start talking to different providers.

Identifying Your Geographic Footprint

Where are your customers? This sounds like a simple question, but the answer determines where your inventory should live. If most of your customers are on the East Coast, but your 3PL is in California, you are going to pay a fortune in shipping and wait a long time for deliveries. Look at your historical sales data. Are there clusters of customers in specific regions? A good 3PL might offer multiple locations, allowing you to split your inventory and get closer to your buyers. This reduces transit times and lowers your shipping costs significantly.

Core 3PL Selection Criteria

Once you have your requirements in hand, it is time to look at the 3PL selection criteria that actually move the needle. There are hundreds of companies out there, but only a few will be the right fit for your specific culture and product. Let us break down the most important factors we found during our research. You will want to pay attention to this part because choosing based on price alone is often a recipe for disaster.

Industry Experience and Reputation

First and foremost, look for sector expertise. Does the 3PL understand your industry? For example, if you are in the beauty space, you want someone who understands fragile glass bottles and temperature sensitivity. If you sell to big box retailers like Walmart or Target, you need a provider who is an expert in retail compliance and EDI. Ask for case studies from clients who look like you. A 3PL that primarily handles heavy industrial machinery might struggle with the fast pace of a high volume e-commerce brand.

Check their track record. How long have they been in business? While there are some great newer companies, longevity often indicates stability. You want a partner who can weather economic storms and labor shortages. Don’t be afraid to ask for references. Talking to a current client about how the 3PL handles mistakes is often more revealing than hearing about their successes. We all make mistakes. What matters is how we fix them.

Technology, Integration, and Visibility

In today’s market, technology is a primary differentiator. A 3PL is only as good as the software they use. You need to know that their Warehouse Management System (WMS) can talk to your e-commerce platform. Whether you use Shopify, Magento, or a custom ERP, the data should flow back and forth in near real time. This supports keeping your inventory levels accurate and ensuring your customers get tracking numbers promptly after their packages leave the dock.

Look for a provider that offers an analytics dashboard. You should be able to see your key performance indicators (KPIs) at any time. This includes things like order accuracy, on time shipping rates, and inventory turnover. According to industry leaders like Gartner, visibility is the top priority for many modern supply chain leaders. If a 3PL cannot give you timely data, they are likely working with legacy systems that can slow you down.

Scalability and Flexibility

You are looking for a partner for today, but also for three years from now. Can this 3PL handle your growth? Ask them about their capacity. If you double your order volume next year, do they have the physical space and the labor force to accommodate you? This is especially important during peak seasons. Some 3PLs get overwhelmed in November and December, leading to shipping delays that can hurt your brand. Make sure they have a proven plan for scaling up during busy times.

The 3PL RFP Process: A Structured Approach

This is where things get official. A Request for Proposal (RFP) is a document you send to potential partners that outlines your needs and asks for their solution and pricing. It might feel like a lot of paperwork, but it is the best way to ensure you are getting the full story. A structured 3PL RFP process reduces the risk of choosing based on a flashy sales pitch or incomplete information. Let us walk through the steps we recommend.

- The Shortlist: Identify 5 to 10 providers that seem like a good fit based on their website and initial reputation.

- The RFI: Send a brief Request for Information. This is a high level “vibe check” to see if they have the right locations, basic services, and technology to even be considered.

- The Detailed RFP: This is the meat of the process. Provide your data, your SKU list, your shipping volumes, and your specific requirements. Ask for a detailed pricing proposal and a description of their operational approach.

- Scoring and Evaluation: Create a spreadsheet and score each response against your criteria. Do not just look at the bottom line. Look at their tech, their culture, and their responsiveness.

- Site Visits: This is non-negotiable. You must see the facility in person.

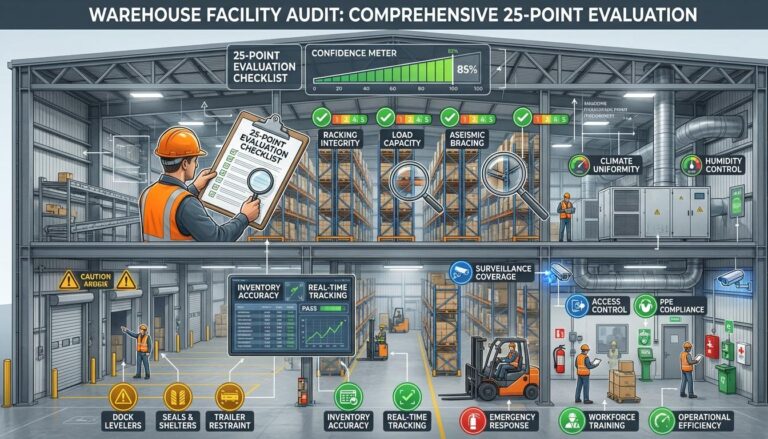

Site visits are the part most people skip, but they are vital. You can tell a lot about a company by walking through their warehouse. Is it clean and organized? Do the employees look engaged or miserable? Are the safety protocols being followed? This is your chance to meet the operations manager, who will be the person actually responsible for your products. To help you during these visits, you should bring a 3PL warehouse evaluation checklist so you don’t miss any critical details.

What we found is that the “soft” side of the business matters just as much as the “hard” data. If a provider is slow to answer your RFP or seems disorganized during the sales process, that is exactly how they will treat your orders. Trust your gut here. If something feels off during the site visit, it probably is. You are looking for a long term partner, not a temporary fix.

Assessing 3PL Capabilities in Depth

Now, let us look under the hood. When we talk about a 3PL capabilities assessment, we are looking at the specific ways they execute their work. It is easy for a sales rep to say they have “great inventory accuracy,” but you want to know the “how.” What are their actual processes? Do they use barcode scanning at every step? Do they perform regular cycle counts instead of just one big physical inventory once a year?

Check their picking methods. Depending on your order profile, they might use zone picking, batch picking, or wave picking. Each has pros and cons for efficiency and accuracy. Ask about their quality control steps. Do they weigh every box before it leaves to ensure the contents match the order? These small details are what prevent shipping errors, which save you money on customer service and returns in the long run.

Transportation and Carrier Management

Your 3PL should be an expert in moving things from point A to point B. Ask about their carrier mix. Do they rely on just one or two major carriers, or do they have a wide network of regional providers? A diverse carrier network is essential for navigating disruptions, like strikes or weather events. You should also ask about their freight audit process. Are they checking every invoice to ensure you are not being overcharged for fuel surcharges or accessorial fees?

What about international shipping? If you plan to grow globally, you need a partner who understands customs brokerage and international duties. Managing cross border logistics is a nightmare if you do it alone. A 3PL with international experience can help you navigate these waters without the usual headaches. This is a great example of where a partner’s expertise pays for itself.

Returns and Reverse Logistics

Let us be real for a moment. Returns are a part of doing business, especially in e-commerce. A 3PL should have a dedicated process for handling them. What happens when a box comes back? Does someone inspect it immediately? Can they refurbish items or repackage them for resale? The faster a return is processed, the faster the inventory is back on your “shelf” and the faster your customer is satisfied. Ask potential partners for their average turnaround time on returns and how they communicate those updates to your team.

Cost Structure and Transparency: Avoiding Hidden Fees

This is the part where most people get burned. 3PL pricing is notoriously complex. You will often see a low “pick and pack” fee, only to be surprised by “account management fees,” “technology fees,” and “inbound receiving fees” later on. Here is what actually matters: the total cost to serve. You need to understand every single line item before you sign.

Common fees you will encounter include:

- Storage Fees: Usually charged per pallet, per shelf, or per cubic foot.

- Inbound Fees: The cost to receive and count your inventory when it arrives.

- Pick and Pack: A fee per order plus a fee for each additional item in the box.

- Packaging Materials: The cost of the box, tape, and dunnage.

- Shipping Rates: The actual cost of the postage or freight.

- Value Added Services: Custom kitting, labeling, or returns processing.

To compare providers effectively, we suggest creating a “typical order” scenario. Give each 3PL the same data: “I have an order with two items, weighing three pounds, going to Zone 5. What is the total cost including the box and the labor?” This forces them to be transparent. It also allows you to see how different pricing models affect your margins. Some 3PLs offer flat rate pricing, which is easier to predict, while others offer highly variable pricing that might be cheaper if you have a very specific order profile.

Transparency is a major green flag. If a 3PL provides a clear, itemized quote and is willing to explain every fee, they are likely a trustworthy partner. If they are vague or use “catch all” categories, be careful. You want a partner who will work with you to reduce costs over time, not one that hides them in the fine print. When it comes time to finalize the deal, make sure you understand the 3PL contract negotiation terms so you are protected against unexpected price hikes.

Risk Management, Compliance, and Culture

It is easy to focus only on the logistics, but the “business” side of the partnership is just as important. You are trusting this company with your inventory, which is essentially your cash. What happens if there is a fire at the warehouse? Do they have adequate insurance? Ask about their business continuity plans. How would they handle a labor strike or a massive power outage? A professional 3PL will have documented plans for these scenarios.

Compliance is another critical area. Depending on what you sell, you might need specific certifications. This could be ISO standards for quality management or specific safety certifications for handling hazardous materials. According to the U.S. Chamber of Commerce, verifying these credentials upfront is a key step in mitigating supply chain risk. Don’t just take their word for it; ask to see the physical certificates during your site visit.

The Importance of Cultural Alignment

Here is something most guides do not mention. You need to actually like working with these people. You will be communicating with your 3PL almost every day. If their culture is rigid and corporate, but your brand is fast moving and scrappy, you are going to clash. Are they proactive? Do they come to you with ideas for saving money or improving efficiency? Or do they just wait for you to tell them what to do?

Look for a partner who views themselves as an extension of your team. This means shared values around quality and customer service. During the RFP process, pay attention to their communication style. Are they helpful and transparent, or do they feel like they are “selling” you? A 3PL with a strong culture of continuous improvement will constantly look for ways to make your supply chain better, which is exactly what you want in a long term partner.

Strategic Considerations for Long Term 3PL Partnerships

Choosing a 3PL is not a “set it and forget it” task. It is the beginning of a relationship that needs to be managed. Once you have selected a partner and moved your inventory, you need a governance structure. This usually means regular business reviews, perhaps once a quarter. This is your time to look at the data together. Are you hitting your KPIs? Where are the bottlenecks? What can both sides do better?

What we found is that the most successful companies treat their 3PL as a strategic advisor. Share your marketing calendar with them. If you have a big sale coming up, tell them weeks in advance so they can staff up. If you are launching a new product line, get their input on the packaging. They see thousands of orders every day and likely have insights that can save you money or improve the customer experience.

Planning for the Future and the Exit

Finally, always have an eye on the future. As your business evolves, your logistics needs will too. Maybe you will need to expand into international markets or open a second warehouse location. Does your 3PL have the network to support that? You also need to think about the “what if” scenarios. If the partnership isn’t working out, how do you leave? Make sure your contract has clear termination clauses and provisions for how your data and inventory will be handed over. It sounds pessimistic, but a clear exit strategy is a sign of a professional and healthy business relationship.

Frequently Asked Questions

What are the most important criteria for choosing a 3PL provider?

The most important factors are industry experience, technology capabilities, and cultural fit. You need a partner who understands your specific product requirements and can integrate seamlessly with your sales channels. Beyond that, scalability and transparent pricing are essential for long term growth. Never settle for a provider who cannot give you timely visibility into your inventory and orders.

How do I start a 3PL selection and RFP process?

Great question. Start by gathering your own data, including order volumes, SKU counts, and customer locations. Once you have a clear picture of your needs, create a shortlist of potential partners and send them a Request for Information (RFI). This helps you narrow the field before you invest the time in a full Request for Proposal (RFP). Always include a site visit and reference checks before making your final decision.

How can I compare 3PL pricing models effectively?

This comes up a lot, and the answer is to look at the total cost to serve. Instead of just comparing individual line items like “pick fees,” create a standardized order scenario and ask each provider to quote the total cost for that order. This includes everything from receiving the item to the final postage. This is the only way to see through “hidden” fees and understand how their pricing will actually impact your margins.

Why is 3PL technology so important?

Technology is the nervous system of your supply chain. Without a modern WMS and strong integrations, you will struggle with inventory inaccuracies and shipping delays. Good technology allows for timely data sharing, which means you always know what is in stock and your customers always know where their packages are. It also enables the analytics you need to make smart business decisions and optimize your costs over time.

How long does it usually take to implement a new 3PL?

The short answer is that it varies, but there is more to it. A simple implementation for a small brand might take four to six weeks. For a larger enterprise with complex integrations and thousands of SKUs, it could take three to six months. This time includes setting up the software integrations, mapping out operational processes, and physically moving your inventory to the new facility. It is important not to rush this process, as a messy “go live” can disrupt your sales and frustrate your customers.

Bringing It All Together

Choosing the right 3PL partner is a journey, and if you have made it this far, you are already ahead of most people. You now have the tools to audit your own business, evaluate potential partners, and navigate the complexities of pricing and technology. Remember, you are not just looking for a warehouse; you are looking for a team that will help you scale your dreams. It takes some work upfront, but the peace of mind that comes with a reliable logistics partner is worth every minute of research.

Take your time with the site visits and the contract negotiations. Ask the hard questions about technology and hidden fees. Most importantly, trust your instincts about the people you will be working with. Logistics is a human business, even with all the robots and software in the world. Now you have everything you need to find the perfect fit. The next step? Start gathering your data and reach out to your first shortlist of providers. You have got this!