3PL vs 4PL: Understanding the Difference and Choosing Right

Are you trying to figure out if your business has outgrown its current shipping setup? Finding the right partner means knowing the exact boundary where 3PL vs 4PL services differ. While general guides cover the basics, you need the specific details that actually help you decide which level of outsourcing fits your operational scale. We are going to get straight into what works, what does not, and exactly what you should do to optimize your supply chain. Let us get specific.

If you are reading this, you probably already know that logistics is more than just moving boxes. You are looking for the detailed breakdown you have been searching for, not a surface-level overview. Most companies reach a crossroads where their internal team can no longer manage the sheer volume of vendors and data. This is where the 3PL vs 4PL debate becomes critical. We have seen this question come up constantly, so let us settle it by looking at the operational reality versus the strategic orchestration.

The Operational Reality of 3PL Execution

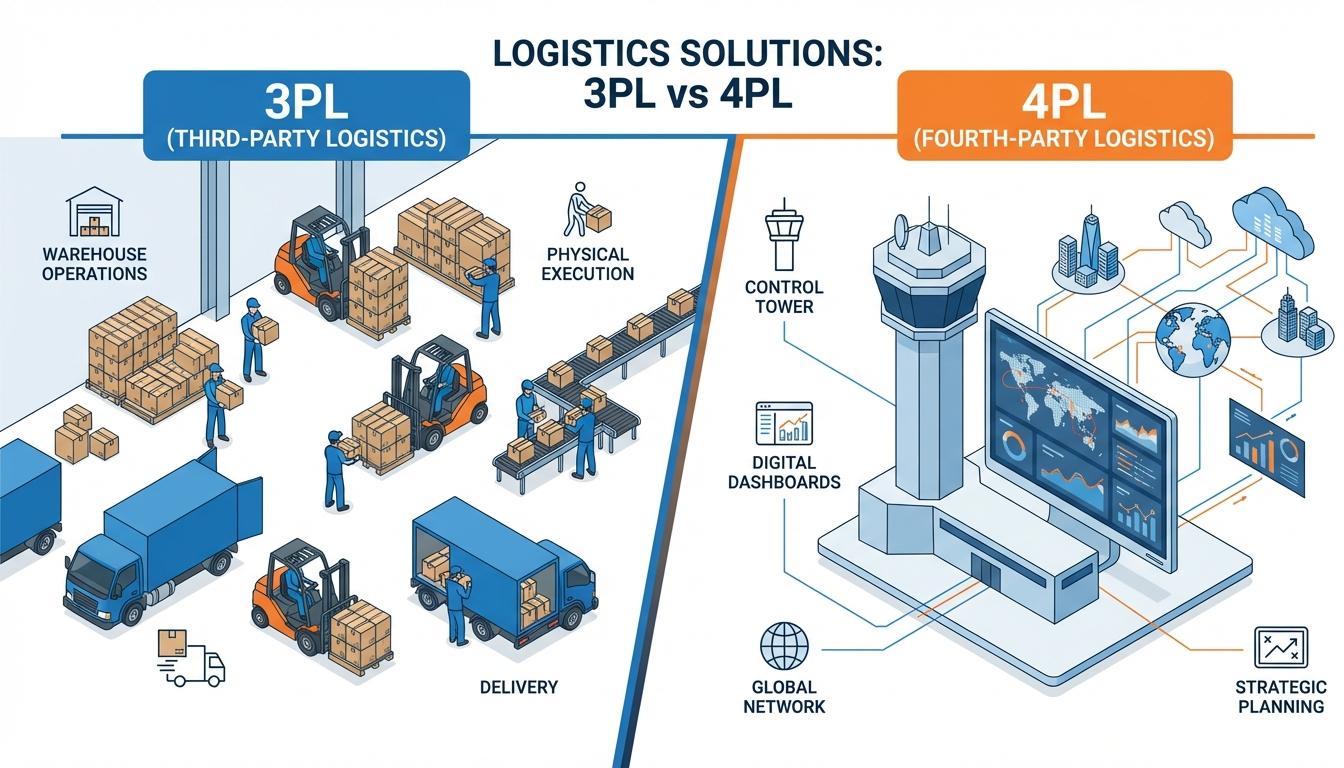

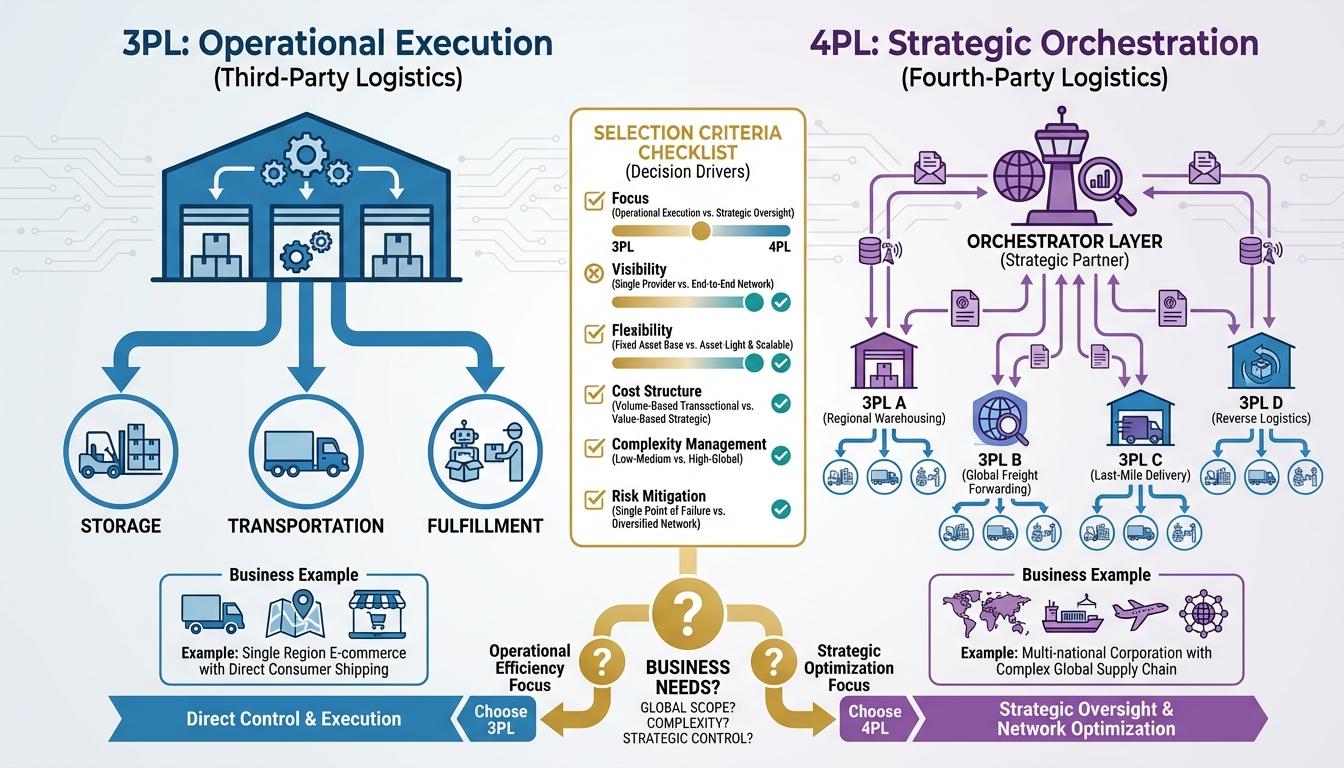

When it comes to third-party logistics, the focus is almost entirely on execution. A 3PL provider acts as a specialized extension of your own team. They take over the day to day heavy lifting so you do not have to own a fleet of trucks or a massive warehouse. Most 3PLs are asset-based, which means they actually own the physical infrastructure used to move your goods. This is the specific situation where a 3PL shines, providing the muscle for your logistics strategy.

Here is what that actually looks like in practice. You retain the strategic control. You decide which markets to enter and how much inventory to hold. Your 3PL partner simply makes it happen by picking, packing, and shipping the orders. They offer specialized services like:

- Warehousing and inventory storage.

- Order fulfillment for ecommerce and retail.

- Freight forwarding and customs brokerage.

- Reverse logistics for returns processing.

- Cross-docking and simple kitting services.

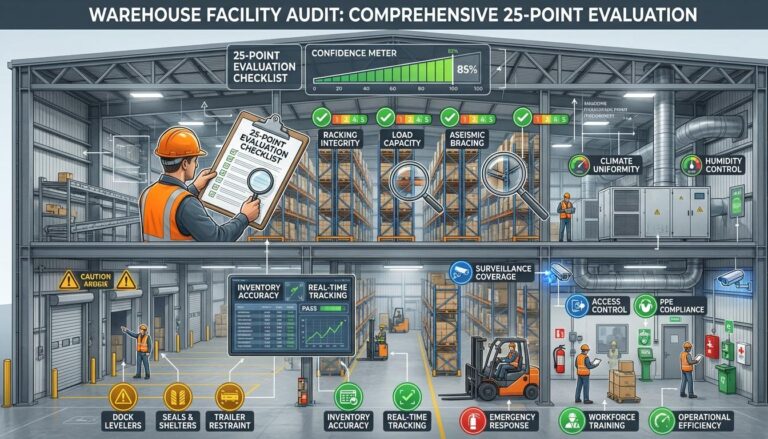

So what does this mean for you? The relationship is usually transactional. You pay for the space you use and the number of boxes they ship. This model is incredibly effective for small to medium-sized businesses that need to scale quickly without huge capital investments. If you are just starting to evaluate your options, you might find our 3PL warehouse evaluation checklist helpful for vetting these providers. The key difference here is that while the 3PL handles the tasks, you still have to manage the 3PL.

The Strategic Orchestration of the 4PL Model

Now for the part you actually came here for. A 4PL, or fourth-party logistics provider, is an entirely different beast. We often call them Lead Logistics Providers or LLPs. Unlike a 3PL, a 4PL rarely owns trucks or warehouses. They are asset-light. Their primary value lies in their ability to manage your entire supply chain from a high-level perspective. They do not just execute tasks. They design the system itself.

The real question is, what does a 4PL do that a 3PL does not? A 4PL acts as your single point of contact for every logistics partner you have. If you have three different 3PLs in three different countries, a 4PL oversees all of them. They integrate your data, manage the contracts, and look for ways to optimize the entire network. According to Inbound Logistics, the 4PL model emerged as supply chains became global and digital, requiring a “control tower” to manage the complexity.

Let us look at this closely. A 4PL provider typically handles:

- Supply chain design and network optimization.

- Management of multiple 3PLs and carriers.

- Advanced technology integration across all platforms.

- Strategic planning and business intelligence.

- Project management for global expansions.

Your best move here is to view a 4PL as a strategic partner rather than a service vendor. They are focused on your long-term business goals, such as reducing working capital or improving sustainability. They often work at the executive level, aligning your logistics with your overall sales and operations planning.

3PL vs 4PL: The Granular Differences

Let us get into the details of how these two models actually compare across the areas that matter most to your bottom line. The short version is that 3PL is about “how to ship,” while 4PL is about “why we ship this way.” This is the detail that changes everything for a growing enterprise.

Control and Governance

In a 3PL arrangement, you are the boss. You manage the relationship, you negotiate the rates, and you troubleshoot when things go wrong. If you enjoy having hands-on control and have the internal staff to manage it, a 3PL is perfect. In a 4PL model, you delegate that authority. The 4PL becomes the primary owner of the strategy. They manage the 3PLs so you do not have to. This frees up your internal team to focus on product development and marketing.

Technology and Data Visibility

This is where the distinction becomes very clear. A 3PL provides operational tech. You will get access to a Warehouse Management System (WMS) or a Transportation Management System (TMS) to track your specific orders. However, a 4PL provides a control tower. This is a central hub that pulls data from your suppliers, your factories, your 3PLs, and your customers. Research from Maersk highlights that 4PLs use this integrated data to provide end-to-end visibility that a single 3PL simply cannot offer.

Asset Ownership

Most 3PLs are asset-based. They have a vested interest in filling their own warehouses and using their own trucks. This can sometimes create a conflict if their assets are not the most efficient choice for your specific needs. A 4PL is usually neutral. Since they do not own the assets, they can choose the best carriers and warehouses for your business without bias. They are focused on finding the most cost-effective solution, even if it means switching vendors.

Economics and Cost Structures

The cost conversation is often where people get confused. Let us cut to what matters. A 3PL is almost always cheaper in the short term. You pay for what you use, and there is very little management overhead. This is why small businesses stick with 3PLs. For more information on navigating these costs, see our guide on how to choose a 3PL, which serves as our main pillar for understanding these relationships.

However, a 4PL typically involves a higher entry cost. You are paying for a management layer and a sophisticated technology stack. So why would anyone do it? The answer lies in long-term system-wide optimization. A 4PL looks at your total landed cost. They might find that by spending more on a specific 3PL, they can save twice as much in inventory carrying costs or duties. The practical takeaway is that 3PLs save you money on shipping, but 4PLs save you money on your entire business model.

Your next step is to evaluate your current logistics spend. If your logistics costs are rising faster than your revenue, or if you are struggling to manage multiple vendor contracts, the management fee of a 4PL might actually be a net saving. This is especially true when you factor in the time your internal team spends on administrative tasks. You might also want to review 3PL contract negotiation terms to see if you can squeeze more value out of your current 3PL before making the jump to a 4PL.

Quick Reference: 3PL vs 4PL at a Glance

- Focus: 3PL handles execution. 4PL handles strategy and integration.

- Assets: 3PL often owns trucks/warehouses. 4PL is usually asset-light.

- Contact Point: 3PL is one of many vendors. 4PL is your single point of contact.

- Technology: 3PL uses WMS/TMS. 4PL uses a Control Tower/BI platform.

- Scale: 3PL is ideal for SMBs. 4PL is built for global enterprises.

- Relationship: 3PL is transactional. 4PL is a strategic partnership.

- Control: You manage the 3PL. The 4PL manages the logistics network for you.

When to Move from 3PL to 4PL

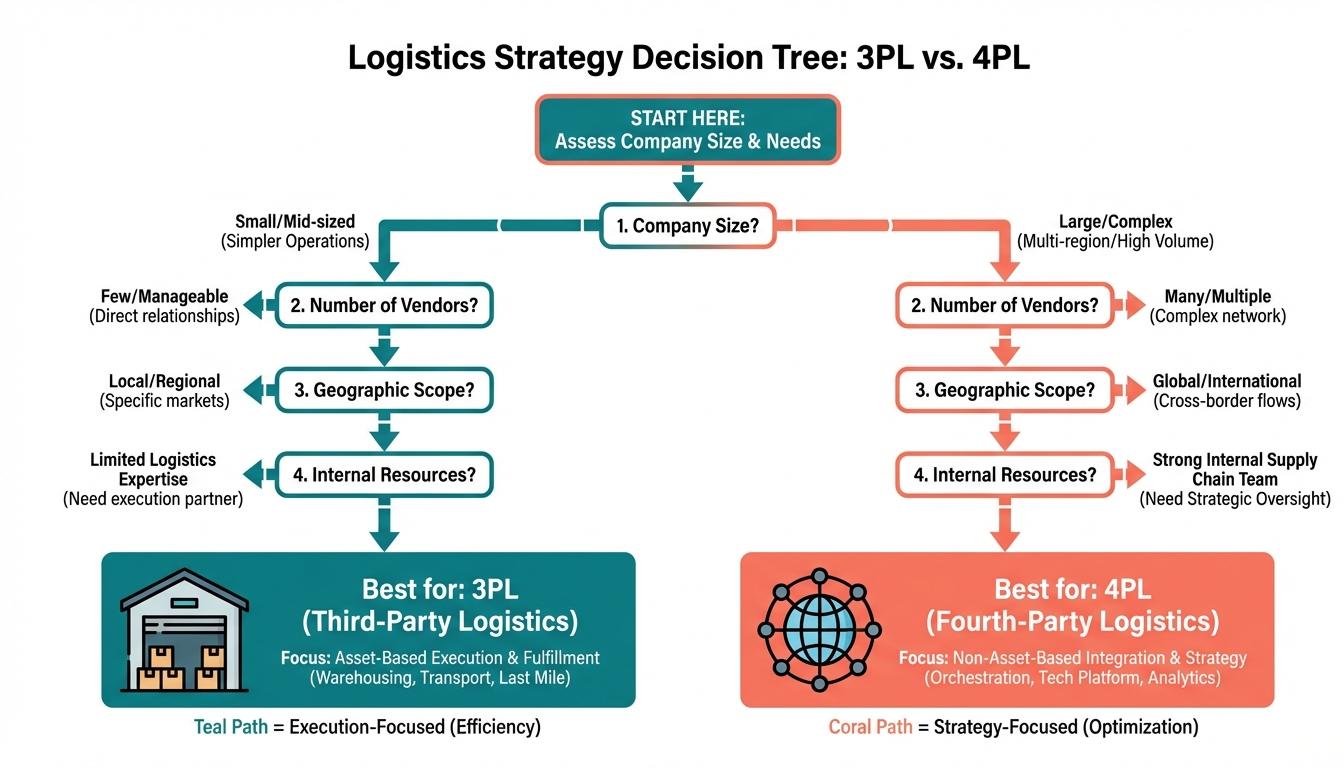

Ready for the specifics? Deciding to move from a 3PL to a 4PL is a major shift. It is not something you do just because you are bored. There are specific triggers that indicate your business is ready for this level of outsourcing. Let us get into the details of those indicators.

The first trigger is complexity. If you are operating in multiple countries with multiple manufacturing sites, managing individual 3PLs becomes a full-time job for an entire department. If you find your team is constantly “putting out fires” instead of planning for the future, you need a 4PL. This is one of those areas where getting it right makes a real difference in your ability to scale.

The second trigger is a lack of visibility. Can you tell, at any given moment, exactly where every piece of inventory is across your global network? If the answer is no, you have a data silo problem. A 4PL specializes in breaking down those silos. They integrate data from every point in the supply chain to give you a “single version of the truth.” This is essential for high-tech, automotive, and healthcare industries where compliance and timing are everything.

Quick reality check here. Transitioning to a 4PL takes time. It involves deep technical integration and a shift in company culture. You are handing over the keys to your supply chain. If you are not ready for that level of transparency and trust, you should stick with the 3PL model for now. For a complete overview of how these relationships fit into your broader strategy, check out our main guide on choosing the right 3PL partner.

The Hybrid Model: Can They Co-exist?

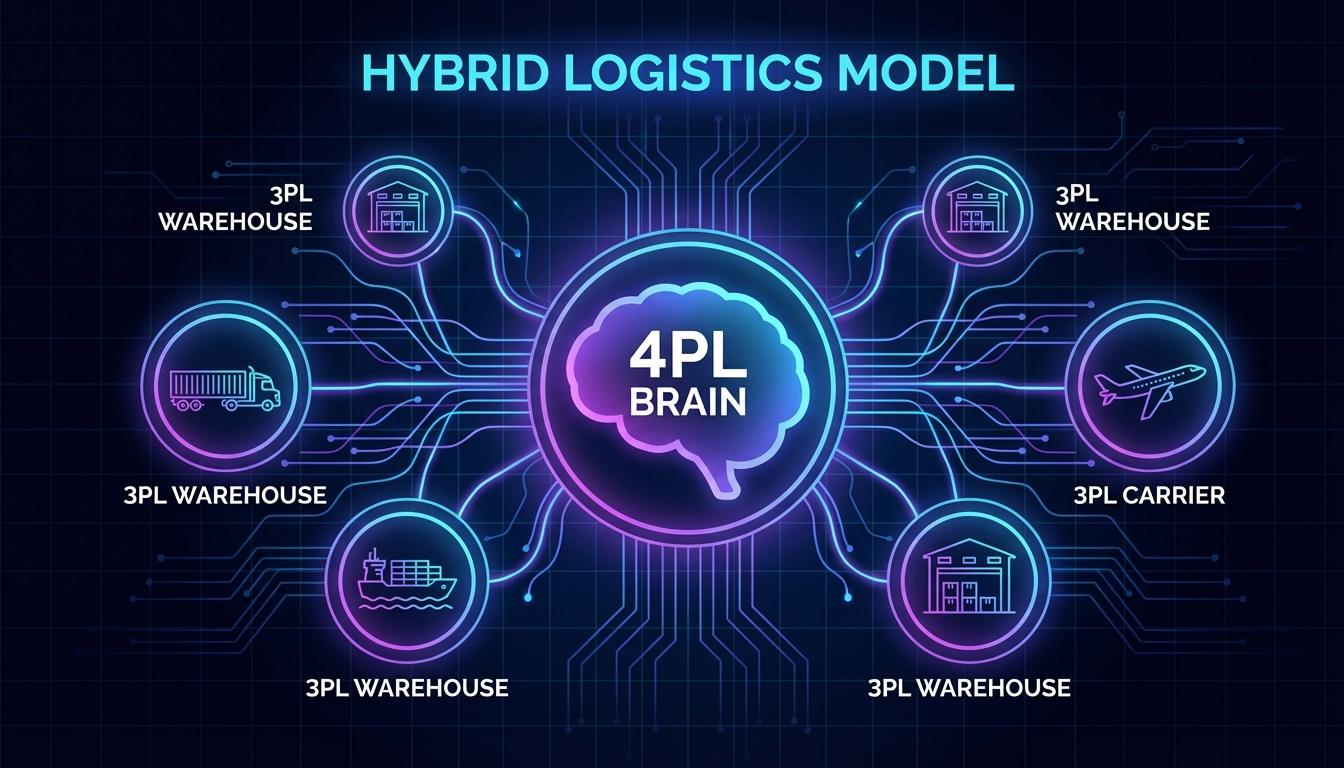

Here is the specific answer to a question we get all the time. Yes, you can use both. In fact, many of the world’s largest companies use a hybrid model. In this scenario, a 4PL acts as the “brain,” while several 3PLs act as the “limbs.” The 4PL designs the routes and selects the partners, while the 3PLs provide the physical warehouses and trucks to move the goods.

This is where it gets practical. In a hybrid model, the 4PL sets the KPIs (Key Performance Indicators) for the 3PLs. They hold the 3PLs accountable for on-time delivery and accuracy. If a 3PL fails to meet these standards, the 4PL is responsible for finding a replacement. This creates a competitive environment that keeps your logistics costs down while maintaining high service levels. The action item here is simple. If you are too big for a single 3PL but not ready to fully relinquish strategic control, look for an “Integrator” that offers both sets of services.

Common Questions About 3PL vs 4PL

What is the main difference between 3PL and 4PL?

The answer is scope. A 3PL focuses on the physical execution of logistics tasks like shipping and storage. A 4PL focuses on the management and optimization of the entire supply chain, often managing multiple 3PLs on your behalf.

Is a 4PL more expensive than a 3PL?

In terms of initial fees, yes. A 4PL requires a higher investment in management and technology. However, a 4PL is designed to lower your total supply chain costs over time through better efficiency and network design, which often leads to higher long-term savings.

Does a 4PL own warehouses?

Typically, no. Most 4PLs are asset-light and do not own trucks or warehouses. They remain neutral so they can select the best 3PLs and carriers for your specific needs without being biased toward their own equipment.

When should an ecommerce brand switch to a 4PL?

An ecommerce brand should consider a 4PL when they expand internationally, manage multiple fulfillment centers, or find that their internal team is overwhelmed by coordinating different shipping carriers and warehouse providers.

Can a 3PL also be a 4PL?

Yes. Many large logistics companies, such as DHL or FedEx, offer both 3PL and 4PL services. They may act as your physical shipper in one region while acting as your lead logistics provider globally. This is often called an “integrated logistics” solution.

Now you have the specific answer you came for. The key point? A 3PL is for doing, while a 4PL is for managing. If you need physical help with orders, look for a 3PL. If you need someone to oversee your entire global operation, a 4PL is the way to go. For the bigger picture on how to vet these companies and set your business up for success, our complete guide on 3PL selection covers everything else you need. Your next step is to map out your current logistics vendors and decide if you are ready to hand over the management to a specialist partner.