How to Evaluate a 3PL Warehouse Before Signing a Contract

Looking for the exact breakdown of how to conduct a 3PL warehouse evaluation? You have come to the right place. While general guides cover the basics, you need the specific details that actually help you determine if a provider can handle your specific product volume and complexity. We are going to get straight into what works, what does not, and exactly what you should do before putting pen to paper. Let us get specific.

Choosing a logistics partner is one of the most significant decisions your business will make. If you are reading this, you probably already know that a bad choice leads to missed deliveries, unhappy customers, and skyrocketing costs. You are looking for the detailed breakdown you have been searching for to avoid those pitfalls. This is not a surface level overview. It is a structured deep dive into the operational reality of third party logistics. For a complete overview of the entire sourcing journey, check out our main guide on how to choose a 3PL. Now, let us look at this closely.

The Foundation of an Objective 3PL Warehouse Evaluation

When it comes to a 3PL warehouse evaluation, the details matter. Most companies fail because they rely on “gut feeling” or a good relationship with a sales representative. The direct answer to avoiding this is a weighted scoring model. You need a template that ranks providers on a scale (usually 1 to 5) across dozens of specific criteria. This ensures your decision is data driven rather than emotional.

What does this look like in practice? We recommend building an evaluation scorecard that focuses on four primary buckets: capability, cost, risk, and strategic alignment. Logistics consultants often use upwards of 80 criteria for complex contracts. For your specific case, you should at least focus on the essentials. Here is the step by step breakdown of how to set up your evaluation framework.

- Define your requirements clearly. Document your SKU count, order profiles, and any specialized needs like temperature control or hazardous materials handling.

- Weight your criteria. Is technology more important than geographic location for your brand? Assign a percentage weight to each category so the final score reflects your priorities.

- Standardize the RFP. Send the same document to every provider. This allows you to compare “apples to apples” when the responses come back.

Your best move here is to involve a cross functional team. Don’t let the supply chain manager make the decision in a vacuum. Bring in IT to vet the systems and Finance to scrutinize the cost models. This collaborative approach uncovers hidden risks early in the process.

Evaluating Warehouse Processes and Operational Excellence

This is where it gets practical. You need to look past the marketing deck and understand how the warehouse actually functions on a Tuesday morning at 10:00 AM. A 3PL operations review should scrutinize the core “flow” of the facility. If the flow is broken, your orders will be delayed.

Let us get into the details of the specific processes you must evaluate. We start at the loading dock and move through to shipping. Every step in between is a potential point of failure. The practical takeaway is that efficiency in one area does not matter if there is a bottleneck in another.

Receiving and Put-Away Efficiency

The “dock to stock” cycle time is a critical metric. This is the time it takes for a shipment to arrive and then become available for sale in the system. Ask the provider for their historical average. If it takes them three days to receive inventory, your cash flow is effectively frozen for those three days. High performing warehouses aim for less than 24 hours.

Inventory Control and Accuracy

How does the 3PL handle cycle counting? If they only do a full physical inventory once a year, run the other way. You want to see a robust cycle counting program where small sections of the warehouse are counted daily. This ensures that the numbers in the system match the physical boxes on the shelf. In practice, this means you will have fewer “out of stock” notifications sent to customers who thought they bought a product.

Picking and Packing Quality

Ask about their picking methodologies. Do they use wave picking, zone picking, or batch picking? The answer should align with your order profile. For example, high volume e-commerce usually requires batch picking to be efficient. You should also check their packing standards. Do they have clear work instructions for how to fold clothes or where to place dunnage? This prevents damage and ensures a professional unboxing experience for your customer.

The 3PL Site Visit: What to Look for on the Floor

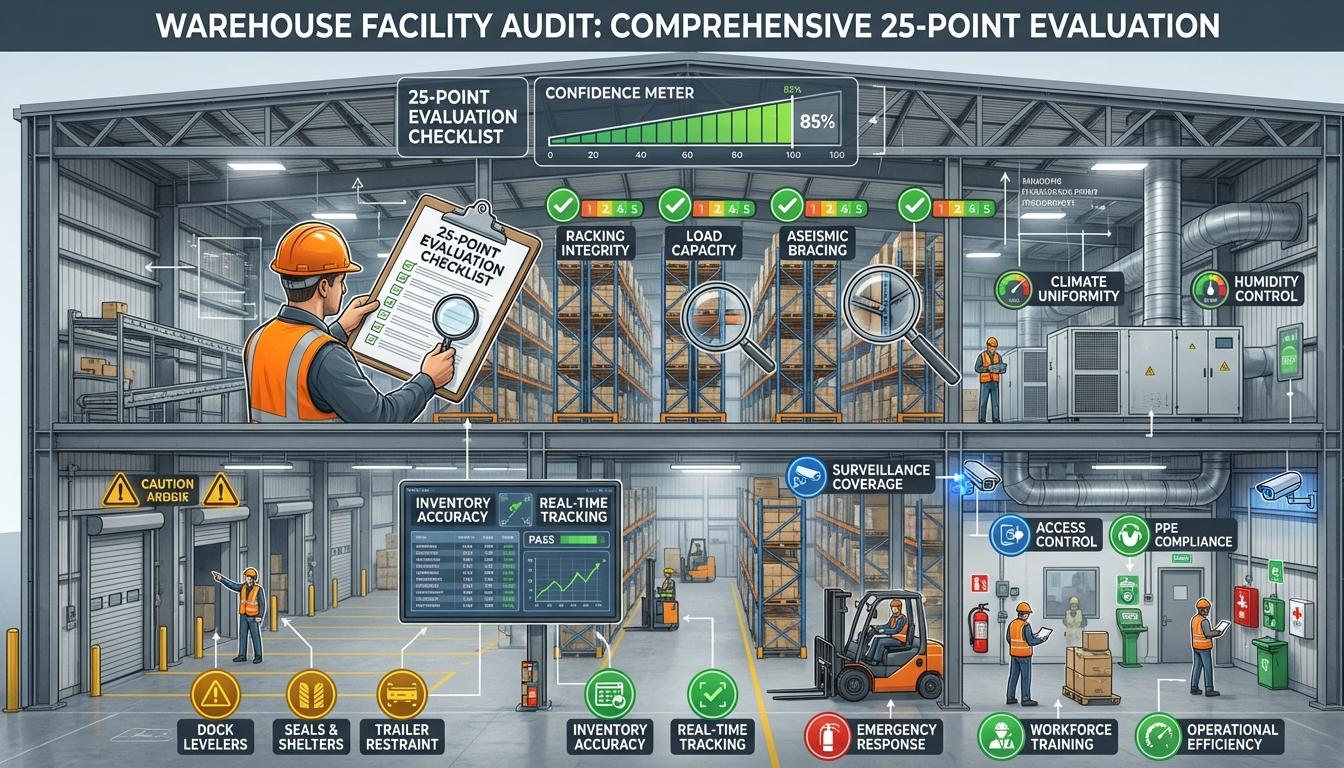

A 3PL site visit is not just a formality. It is the most important part of your evaluation. It is your chance to validate every claim made in the RFP. Experts recommend including site visits to finalist 3PLs as a mandatory step. If a provider is hesitant to let you see the floor, that is a massive red flag.

What should you do right now? Schedule a full facility tour. When you arrive, don’t just follow the sales rep. Look at the corners of the warehouse. Is the facility clean? Are the aisles clear of debris? A messy warehouse usually indicates sloppy processes and a lack of pride in the work. Here is the specific situation where this applies: a warehouse that ignores “housekeeping” is significantly more likely to lose your inventory or ship the wrong item.

The real question is, how do they handle peak season? During your 3PL facility tour, ask to see their labor planning boards. Look for visible KPIs (Key Performance Indicators) posted for the staff to see. You want to see “real time” dashboards that show picking accuracy and hourly throughput. This proves the management team is actually managing the floor rather than just reacting to fires. You should also take a moment to meet the operations manager. This is the person who will actually be responsible for your account. Do they seem knowledgeable? Are they transparent about their challenges? Cultural fit starts here.

Technology and Information Systems Assessment

In the modern supply chain, a 3PL is only as good as its software. This is exactly what you need to know: the Warehouse Management System (WMS) is the digital spine of the operation. You need to ensure their technology can talk to your e-commerce platform or ERP without constant manual intervention.

According to research from the Council of Supply Chain Management Professionals, technology integration is a top three reason why 3PL relationships fail. You want to see a demo of their system in action. Don’t settle for screenshots. Ask them to show you how a return is processed in the system or how they handle a backorder. This level of detail changes everything.

- WMS Capabilities: Does it support real time inventory tracking? Can it handle the complexity of your SKUs (e.g., lot tracking, expiration dates)?

- Integration Options: Do they have pre-built APIs for Shopify, Amazon, or NetSuite? Custom integrations are expensive and take months to build.

- Reporting and Visibility: Will you have a portal to see your inventory levels and order status in real time? If you have to email a rep to get a report, the technology is outdated.

- Data Security: Ask about their data backup protocols and cybersecurity measures. Your customer data is at stake.

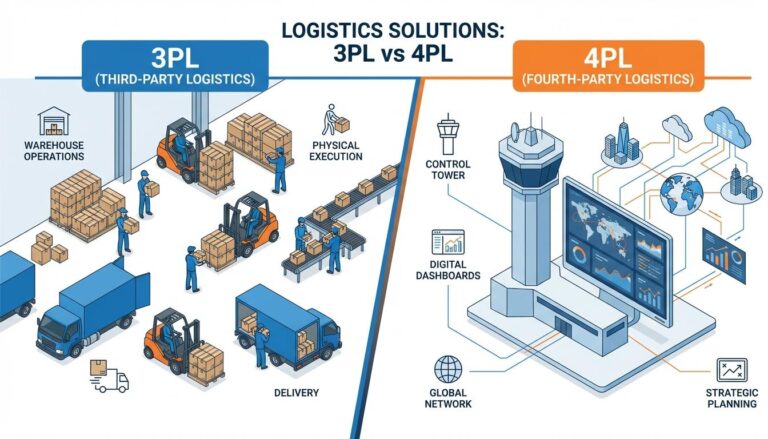

Your next step is to request an IT workshop with their technical team. This is a common practice for serious evaluations. It allows your developers to talk to their developers to ensure the data flow will be seamless. To understand more about the different types of providers you might be integrating with, read our breakdown on 3PL vs 4PL differences.

Performance Metrics and Benchmarking

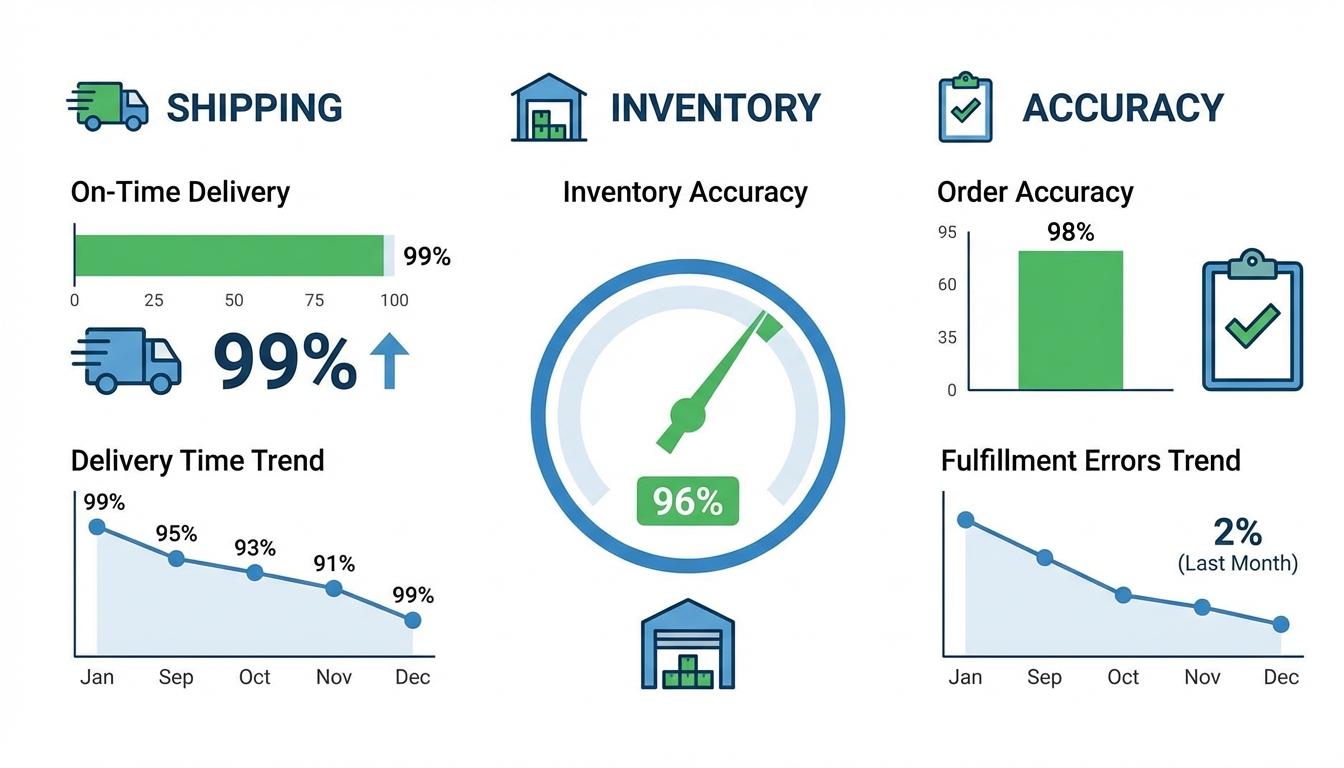

The short version is this: if you can’t measure it, you can’t manage it. A thorough distribution center evaluation must include a review of the provider’s KPIs. You aren’t just looking for high numbers. You are looking for consistent numbers. Ask for a report of their performance over the last six months, specifically during their busiest periods.

Here is the specific answer to which KPIs matter most. Focus on these five metrics. They provide the most accurate picture of warehouse health:

- On-Time Shipment Rate: The percentage of orders that leave the dock by the promised cutoff time. Aim for 99% or higher.

- Inventory Accuracy: The variance between system records and physical counts. High performing sites stay above 99.5%.

- Order Pick Accuracy: How often the correct items are picked. Even a 1% error rate can lead to massive returns costs.

- Dock-to-Stock Time: As mentioned before, how fast inventory becomes sellable.

- Complaint Resolution Time: How quickly do they respond when something goes wrong? This measures their commitment to customer service.

The direct answer is that these metrics should be baked into your Service Level Agreement (SLA). The contract should clearly define what happens if these targets are missed. For more on how to structure these agreements, see our guide on 3PL contract negotiation terms. The practical takeaway here is that performance data should be transparent and reviewed monthly, not just when there is a problem.

Quick Reference: 3PL Warehouse Evaluation at a Glance

If you are in a hurry, here are the most critical points to keep in mind during your assessment.

- Standardized Scoring: Use a weighted template to compare providers objectively.

- Visual Inspection: Use the site visit to check for cleanliness, safety, and organization (5S).

- Technology Check: Ensure the WMS integrates seamlessly with your existing tech stack.

- Labor Model: Verify their ability to scale staff up or down during peak seasons.

- Location Suitability: Proximity to major ports and highways is essential for reducing transit times.

- Reference Checks: Speak with current clients who have similar product profiles to yours.

- SLA Alignment: Ensure all KPIs are clearly defined and tied to performance penalties or rewards.

Common Questions About 3PL Warehouse Evaluation

What are the most important criteria to evaluate when choosing a 3PL warehouse?

The most important criteria are service performance, technology compatibility, and scalability. You need to know they can ship accurately today and have the space and systems to support your growth three years from now. Location and cost are important, but they cannot compensate for poor operational execution.

Why is a 3PL site visit necessary before final selection?

The answer is simple: marketing materials often hide operational flaws. A site visit allows you to see the real world safety practices, meet the leadership team, and verify that the facility can actually handle your specific inventory volume. It is the only way to gauge the “culture” of the provider.

How often should I perform a warehouse audit or 3PL operations review?

We recommend a formal warehouse audit at least once a year. However, you should be reviewing KPI dashboards monthly. Regular check ins help identify small process drifts before they become major service disruptions for your customers.

What is a “red flag” during a 3PL facility tour?

A messy, disorganized floor is the biggest red flag. You should also watch out for lack of visible safety signage, unhappy looking employees, or outdated material handling equipment. If the facility looks neglected, your inventory will likely be treated with the same lack of care.

How do I compare 3PL costs to in-house operations?

To compare fairly, you must include “fully loaded” costs. This means accounting for rent, utilities, labor, benefits, equipment leases, and management time. Most companies find that while 3PLs have higher per unit costs, they save money by converting fixed costs into variable costs.

Now you have the specific answer you came for. A 3PL warehouse evaluation is not a quick task. It requires a structured approach and a willingness to look at the “unfiltered” side of a provider’s operation. The key point is that the effort you put in now prevents a disastrous transition later. Your next step is to download or create a weighted evaluation scorecard and start scheduling those site visits. For more context on the broader selection process, refer back to our 3PL selection guide. Getting the evaluation right is the only way to ensure a long term, profitable partnership.