Optimizing Your Warehouse Receiving Process

Are you looking for the exact breakdown of the warehouse receiving process? You have come to the right place. While general logistics guides cover the basics, you need the specific details that actually help you eliminate dock congestion and inventory errors. We are going to get straight into what works, what does not, and exactly what you should do to master your inbound operations. Let us get specific.

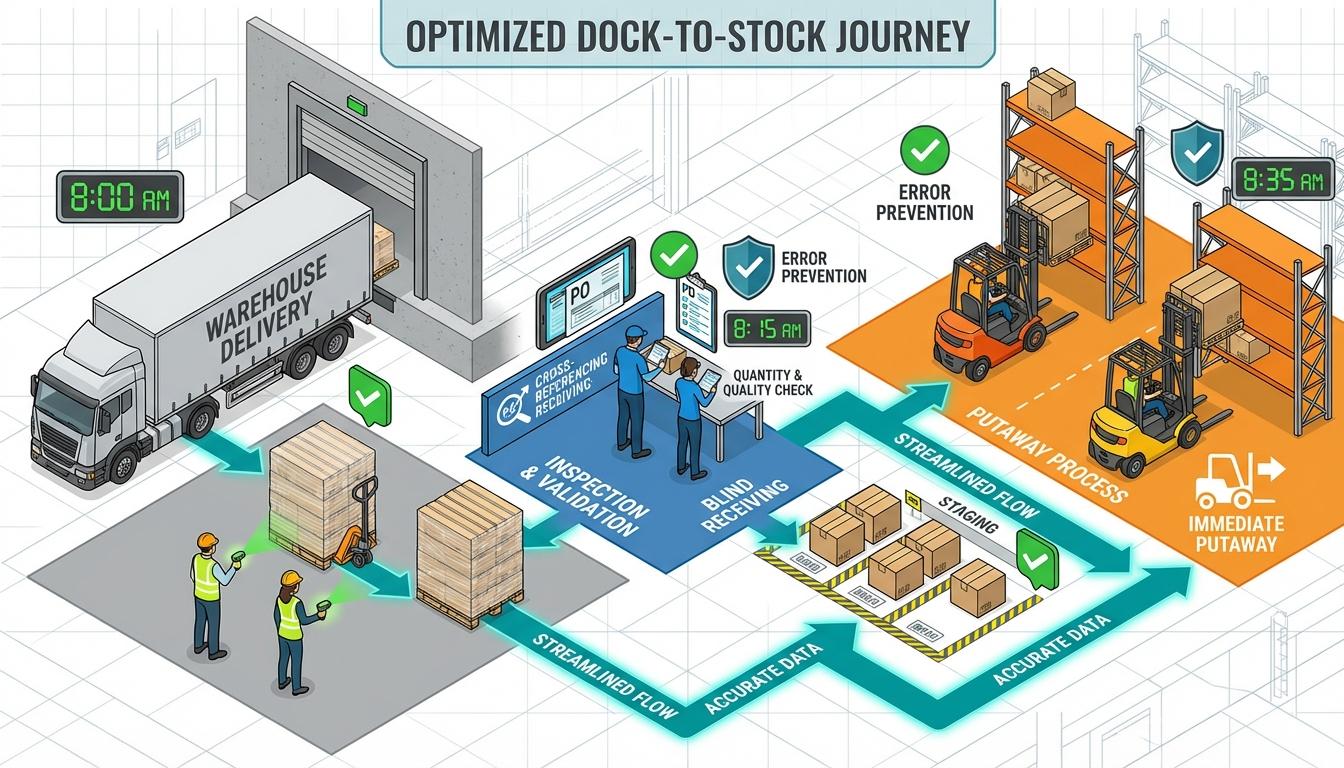

If you are reading this, you probably already know that the receiving dock is the heartbeat of your facility. It is where your inventory begins its life cycle. If things go wrong here, the errors ripple through every other department. You are looking for the detailed breakdown of how to turn a chaotic dock into a precision engine. This is the detailed breakdown you have been searching for. We will cover everything from dock scheduling to the final dock to stock process that makes your inventory visible and ready for sale.

The Foundation: Pre-Receiving and Dock Scheduling

The warehouse receiving process does not actually start when the truck mirrors appear in the dock bay. It starts days or even weeks earlier. When it comes to inbound receiving, the most common mistake is being reactive. If you wait for the driver to hand you a Bill of Lading to find out what is on the truck, you have already lost the efficiency battle. Here is the specific answer to solving that: Advance Shipping Notices (ASNs).

An ASN is an electronic document sent by your supplier that tells you exactly what is coming. It includes SKUs, quantities, pallet counts, and even expiration dates or serial numbers. When your team has this data ahead of time, they can prepare the WMS for the incoming shipment. This allows for a one scan verification instead of manual data entry. Here is what that actually looks like in a high-performing facility. The staff knows exactly how many staging lanes to clear and which specialized equipment, such as heavy duty forklifts or slip sheet attachments, they need to have ready.

Let us look at dock scheduling closely. Without a formal appointment system, you face the nightmare of five trucks showing up at 8:00 AM and none at 2:00 PM. This creates labor waste and safety hazards. Your best move here is to implement a dock management system where carriers must book a specific window. This allows you to level load your labor. You can assign more people to a complex container unload and fewer to a simple pallet drop. The practical takeaway is simple. If you control the schedule, you control the dock.

Arrival and Safety: More Than Just Unloading

When the truck arrives, the clock starts on your dock to stock process. But before a single pallet moves, safety and documentation take priority. This is one of those areas where getting it right makes a real difference. We have seen too many accidents caused by “dock walk,” where a truck creeps away from the leveler during unloading. Here is the step by step breakdown of a safe arrival protocol.

- The driver checks in and provides the Bill of Lading (BOL).

- Staff verify the PO number against the scheduled appointment.

- The truck is backed into the assigned dock and the engine is turned off.

- Wheel chocks are applied, or automatic dock locks are engaged.

- The trailer seal is inspected for tampering before being broken and recorded.

Once the trailer is secure, the physical unloading begins. Many best practice guides recommend unloading back to front. This means the items scheduled for the earliest processing are accessible first. This reduces extra handling and keeps the flow moving toward the warehouse interior. During this stage, your team should be moving goods into clearly marked staging lanes. These lanes act as a buffer zone. They prevent the receiving dock operations from becoming a bottleneck by separating the “unloading” task from the “detailed counting” task.

Efficiency here is tied to your physical environment. If your dock layout is cramped, your throughput will suffer regardless of how fast your team works. For a complete overview of how your physical space impacts these workflows, check out our main guide on warehouse layout optimization. Proper spacing in the staging area allows forklifts to maneuver without waiting for others to clear the path.

The Three-Way Match: The Gold Standard of Accuracy

What is the actual answer to achieving 99 percent inventory accuracy? It is the three-way match. This is the heart of the goods receipt process. You are comparing three distinct records to ensure they are identical. First, you have the Purchase Order (what you intended to buy). Second, you have the Packing List or ASN (what the supplier says they sent). Third, you have the physical count (what actually came off the truck).

Let us get into the details of why this matters. If a supplier bills you for 100 units but only 90 arrive, and your receiving team just “rubber stamps” the paperwork, you have lost money and skewed your inventory levels. This is where the receiving dock operations become a financial control point. Your team must scan every pallet or individual carton depending on your specific requirements. We recommend using handheld scanners that provide real time feedback. If a staff member scans an item that is not on the PO, the system should immediately alert them.

So what does this mean for you when things do not match? This is where Overages, Shortages, and Damages (OS&D) come in. You must have a standardized way to record these discrepancies immediately. If a carton is crushed, it should be photographed and noted on the BOL before the driver leaves. The action item here is simple. Never accept a shipment with visible damage without a signed acknowledgment from the carrier. This is the detail that changes everything when it comes to filing successful freight claims later.

Receiving Inspection and Quality Control

The warehouse receiving process is your last line of defense against poor quality products reaching your customers. While verification focuses on quantity, receiving inspection focuses on condition and compliance. For your specific case, this might mean a simple visual check, or it might involve a rigorous lab test. According to the Association for Supply Chain Management (ASCM), high performing warehouses integrate quality checks directly into the receiving flow to prevent “re-work” later.

Here is how to apply this without slowing down the dock. Use a sampling plan. You do not always need to inspect 100 percent of the items. Instead, use an Acceptable Quality Level (AQL) standard to determine how many units per pallet need a deep dive. For example, in the food and beverage industry, this step often includes checking the trailer temperature and the internal temperature of the goods. If the shipment was supposed to stay at 34 degrees but arrived at 45 degrees, the entire load might be rejected.

Items that fail inspection should be moved to a designated quarantine zone. This area must be physically separated from “good” inventory to prevent accidental picking. In your WMS, these items should be placed in a non-pickable status. This ensures that while the goods are physically in the building, they cannot be allocated to an order. Ready for the specifics on what happens next? Once an item passes inspection, it is ready for the final step of the inbound receiving journey.

System Entry and the Goods Receipt Posting

Now for the part you actually came here for. How do you make the inventory “live”? This is the system entry phase. Once the physical count and quality checks are done, the goods receipt must be posted in your ERP or WMS. This action updates your financial records and makes the stock available for sale. In modern warehouse receiving, this is often done by generating a License Plate Number (LPN) or a unique pallet ID.

The key difference is between “inventory on hand” and “inventory available.” Until that system entry is finalized, your sales team might think you are out of stock when the product is actually sitting right on your dock. The goal is to minimize the time between the truck arrival and this system update. This is the metric we call dock-to-stock time. To keep this time low, many facilities use mobile workstations. This allows receiving clerks to print labels and post receipts right at the staging lane rather than walking back to a central office.

After the system entry, the goods move to the putaway phase. This is where the inbound logistics team hands off the product to the storage team. To maximize your space and speed, you should use directed putaway. The WMS should tell the operator exactly where to take the pallet based on how fast the item sells. For more on how to organize your inventory for maximum efficiency, you can read about our strategies in the warehouse slotting guide. Proper placement during this stage directly determines how fast you can pick the item later.

Quick Reference: Warehouse Receiving at a Glance

- Pre-Receiving: Use ASNs and dock appointments to plan labor and equipment.

- Unloading: Secure the trailer and move goods into clearly marked staging lanes.

- Verification: Perform a three-way match between the PO, Packing List, and Physical Count.

- Inspection: Check for damage and compliance; quarantine any non-conforming items.

- Recording: Document all OS&D (Overages, Shortages, and Damages) immediately.

- System Entry: Post the goods receipt to update inventory and financial records.

- Handoff: Apply LPN labels and move items to their assigned storage or cross-dock locations.

The Downstream Impact of Strong Receiving

This is where it gets practical. Why should you care this much about the details of receiving? Because every minute saved on the dock is a minute earned in fulfillment. A smooth warehouse receiving process ensures that your pickers are never hunting for “ghost inventory” that was received but never put away correctly. When receiving is accurate, your order accuracy naturally climbs. According to OSHA, a well organized receiving area also significantly reduces the risk of workplace injuries by eliminating clutter and congestion.

The real question is how this affects your customer. If your receiving process is slow, your lead times increase. If it is inaccurate, you ship the wrong products. By focusing on these inbound details, you are actually protecting your outbound reputation. Once the goods are properly received and stored, they enter the next phase of the warehouse lifecycle. To see how these received goods eventually leave the building, you might find our breakdown of the pick pack ship process helpful for understanding the full circle of operations.

Common Questions About the Warehouse Receiving Process

What is the most important KPI for receiving?

The direct answer is dock-to-stock time. This measures the total elapsed time from when a truck arrives to when the items are available in a pickable location. Reducing this number improves your cash flow and service levels. Other important metrics include receiving accuracy and OS&D rates per thousand units.

How do you handle a shipment with no PO?

The short version is: do not unload it. Accepting shipments without a Purchase Order creates massive administrative headaches and inventory errors. Your best move here is to have a “No PO, No Pay” policy. If a truck arrives without a valid PO in the system, the driver should be turned away until the procurement team can resolve the issue.

What is the difference between a BOL and a Packing List?

Here is the specific difference. A Bill of Lading (BOL) is a legal contract between the shipper and the carrier; it focuses on the shipment as a whole (e.g., “10 pallets of general merchandise”). A Packing List is a detailed document from the supplier that lists the specific SKUs and quantities inside those pallets.

Should we use cross-docking during receiving?

Yes, and here is why. If you have backordered items or high-velocity products that need to go out immediately, cross-docking allows you to move them directly from the receiving dock to the outbound shipping dock. This bypasses the putaway and storage steps entirely, saving massive amounts of labor and time.

When it comes to the warehouse receiving process, the details matter. We have seen that a disciplined approach to dock scheduling, the three-way match, and quality inspection can transform a facility from a bottleneck into a competitive advantage. The practical takeaway is that you cannot manage what you do not measure. Start by tracking your dock to stock time and your OS&D rates. These numbers will tell you exactly where your process is breaking down.

Your next step is to audit your current staging area. Is it clearly marked? Are your team members using handheld scanners for every single transaction? If not, that is your starting point. By tightening these specific inbound receiving steps, you are building a foundation for a faster, more accurate, and more profitable warehouse. Stick to the protocols, leverage your technology, and keep your dock clear. Your entire supply chain will thank you.