Monitoring Supplier Financial Risk Before It Impacts You

Your main supplier goes bankrupt tomorrow. What happens to your production line? If you do not have a clear answer, you are not alone. Many organizations realize the importance of supplier financial risk monitoring only after a critical vendor fails to deliver. This is more than just a “death watch” for companies on the brink. It is a proactive strategy to ensure your supply chain remains resilient and your operations stay profitable. We are going to get straight into what works, what does not, and exactly what you should do to protect your business. Let us get specific.

You probably already know that financial instability is a major threat. You have likely seen headlines about global disruptions causing even established vendors to stumble. But you are looking for the detailed breakdown, not a surface level overview. While a broader supply chain risk management framework covers many bases, financial monitoring requires its own specialized set of tools and metrics. This is the focused expertise you need to turn vague worries into an actionable defense plan.

The Essential KPIs for Supplier Financial Health

When it comes to supplier financial risk monitoring, the details matter. You cannot rely on a supplier saying they are doing fine. You need to look at the hard numbers. We have seen this question come up constantly, so let us settle it. There are specific financial ratios that act as early warning signals for supplier credit risk. If you know what to look for, you can often spot trouble months before it results in a bankruptcy filing.

The first metric to track is the equity ratio. This measures a company’s financial solidity by comparing its total equity to its total assets. A healthy supplier usually maintains an equity ratio of 30 percent or higher. If you see this drop significantly, it means the supplier is becoming increasingly dependent on debt. For example, we have seen cases where an automotive firm spotted a supplier equity ratio falling from 35 percent to 18 percent. By catching this early, they were able to secure bank guarantees and activate backup suppliers before a total collapse occurred.

Liquidity ratios are your next priority. These tell you if a vendor has enough cash or liquid assets to meet their short term obligations. The current ratio is a standard benchmark here. You also need to look at the debt to equity ratio to assess long term supplier viability. A ratio higher than 2 to 1 is a major red flag. It suggests that the supplier is heavily leveraged and might struggle to survive an economic downturn or a sudden drop in orders.

Do not forget to monitor Accounts Receivable (AR) days. You can calculate this by taking the AR balance, multiplying it by 365, and dividing it by total revenue. If this number is climbing, the supplier is struggling to collect cash from its own customers. This creates a cash flow squeeze that eventually trickles down to their ability to fulfill your orders. Your next step is to request these figures quarterly from your most critical partners.

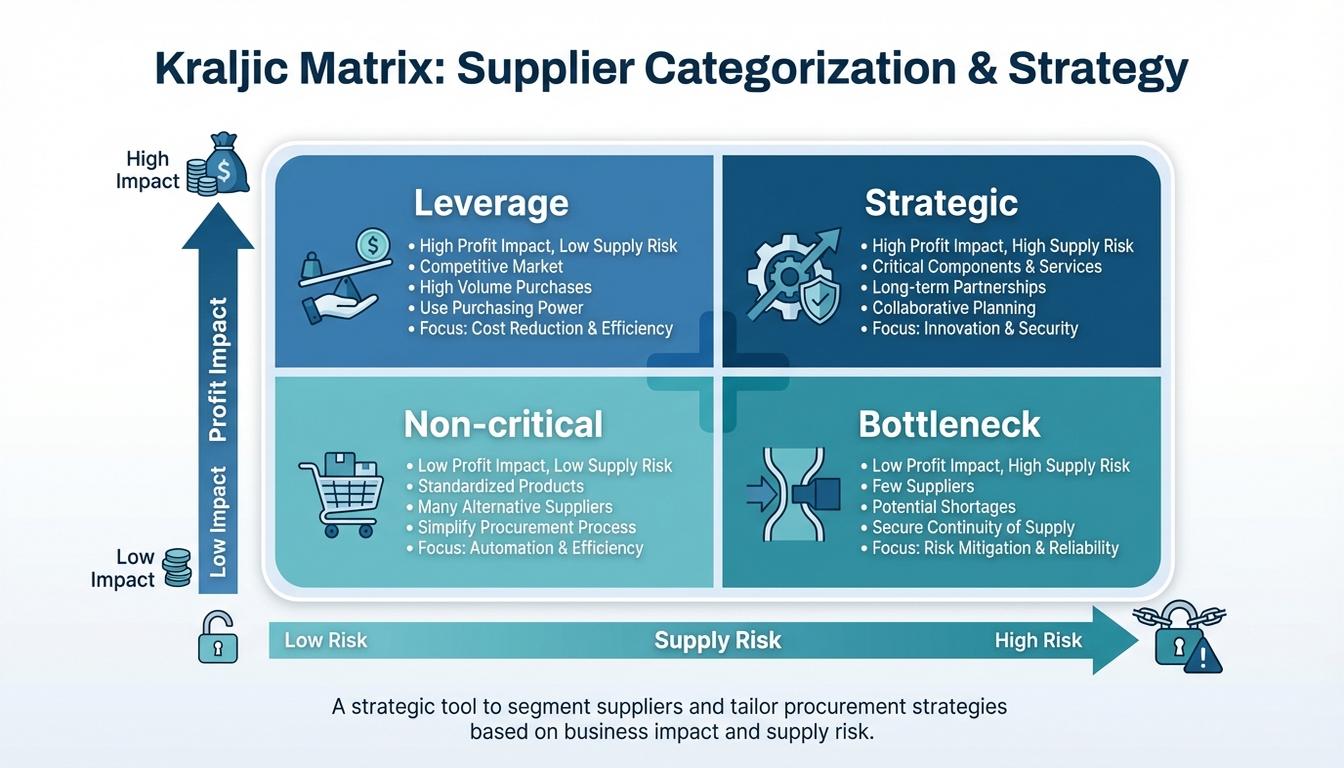

Using the Kraljic Matrix to Prioritize Monitoring

You cannot monitor every single vendor with the same level of intensity. It is simply not efficient. This is where the Kraljic Matrix becomes an essential tool for vendor financial health assessments. By categorizing your suppliers based on profit impact and supply risk, you can decide where to focus your limited resources. The real question is how you segment your base to avoid missing a critical failure.

Strategic suppliers are those with a high impact on your profit and a high supply risk. These are the partners who provide unique components or services that are difficult to replace. For these vendors, we recommend a rigorous, continuous monitoring process. This includes quarterly financial reviews and real time credit alerts. You should treat these suppliers as an extension of your own company. Their financial failure is your financial failure.

Bottleneck suppliers might have a lower profit impact, but they carry a high supply risk because they are often sole source providers. Even if the spend is low, a bankruptcy here can halt your entire production. For these, a semi annual financial stability assessment is usually sufficient, combined with a plan for diversification. Leverage and non critical suppliers require less frequent checks. An annual credit report might be all you need for a vendor providing office supplies or generic packaging.

The practical takeaway is that your monitoring frequency should match the supplier’s importance. Most people get it wrong because they try to do everything at once or nothing at all. The solution is actually straightforward once you understand which partners truly hold the keys to your continuity. Once you have categorized your suppliers, you can better align your efforts with your supply chain risk mapping initiatives to see where financial holes might exist in your network.

Establishing a Continuous Monitoring System

Waiting for an annual report is a recipe for disaster. Credit monitoring for suppliers must be a continuous process to be effective. Here is what that actually looks like in a modern procurement department. You need a mix of automated tools and human judgment to stay ahead of the curve. Static data is dead the moment it is printed, so you need feeds that update in real time.

Many large enterprises now use third party services to provide supplier credit risk scores. According to research from CAPS Research, about 72 percent of large organizations utilize specialized tools like Dun & Bradstreet, Experian, or CreditRiskMonitor. These services aggregate trade data, payment behaviors, and public filings into a single score. When a score drops below a certain threshold, your team should receive an immediate alert. This allows you to ask questions while there is still time to pivot.

So what does this mean for you? It means moving away from spreadsheets and toward centralized data platforms. A good system will consolidate financial statements, contract terms, and news feeds into one dashboard. You should also watch for qualitative red flags. Are they losing key executives? Is there a sudden change in their payment terms to you? Are there rumors of a merger or acquisition? These are often the precursors to a formal credit score drop.

The action item here is simple. Set up automated alerts for your top 20 percent of suppliers. Do not wait for a scheduled review to check their health. If a supplier starts paying other vendors late, you want to know about it immediately. This level of oversight helps you manage supplier bankruptcy risk before it becomes an emergency. It also gives you leverage in negotiations, as you will have a clearer picture of their financial standing than they might realize.

Mitigation Strategies for High Risk Suppliers

What do you do when the monitoring system flashes red? This is where it gets practical. Identifying a risk is only half the battle. You need a set of pre-defined plays to run when a supplier’s financial health deteriorates. The goal is to minimize your exposure without prematurely killing a valuable partnership. Your best move here is a combination of contractual protections and operational adjustments.

First, look at your inventory. If a critical supplier is showing signs of instability, you might want to build a buffer stock. We have seen companies successfully use a 90 day safety stock to bridge the gap while they onboard a new vendor. This buys you time and prevents a total stockout. Along with this, you should revisit your contracts. Ensure you have clauses that allow for audits and require the supplier to provide updated financial documents upon request.

Diversification is another powerful tool. If you are 100 percent dependent on a single high risk supplier, you are essentially gambling with your production. Try to qualify at least one alternative source for every critical component. This is especially important when dealing with geographic supply chain risk, where regional economic instability can impact several suppliers at once. Dual sourcing might cost more in the short term, but it is much cheaper than a factory shutdown.

- Request bank guarantees: For critical orders, ask the supplier to provide a guarantee that protects your prepayments.

- Shorten payment cycles: In some cases, paying a struggling but vital supplier faster can help stabilize their cash flow.

- Tighten SLAs: Increase the frequency of performance reviews to ensure quality does not slip as they cut costs.

- Identify secondary sources: Have a “warm” backup ready to go who has already passed your quality checks.

The Role of Technology and AI in Risk Assessment

Let us look at this closely. The future of supplier financial risk monitoring is not just in reacting to data, but in predicting it. Machine learning and AI agents are now being used to scan thousands of data points to identify patterns that human analysts might miss. This is the detail that changes everything for proactive procurement teams. Technology can now forecast cash flow stress before it even shows up on a balance sheet.

AI models can analyze news sentiment, social media, and even satellite imagery of factory lots to gauge activity levels. If an AI agent notices a 20 percent decrease in truck traffic at a supplier’s main facility, it can flag that as a potential sign of a slowdown. When combined with traditional financial stability assessment data, this creates a 360 degree view of risk. You are no longer just looking at where the supplier has been, but where they are going.

For your specific case, you should look for tools that offer predictive scoring. These models compare a supplier’s current behavior against historical data from thousands of companies that eventually went bankrupt. They look for the “fingerprints” of failure, such as a specific sequence of late payments combined with a rising debt load. This allows you to take action months earlier than traditional methods. It transforms your risk management from a defensive chore into a competitive advantage.

Quick Reference: Supplier Financial Monitoring at a Glance

- Key KPIs: Equity ratio (30%+), Current ratio (>1.0), Debt-to-Equity (<2:1), and AR Days.

- Priority: Use the Kraljic Matrix to focus on Strategic and Bottleneck suppliers.

- Monitoring Frequency: Quarterly for critical partners, annual for non-critical.

- Red Flags: Credit score drops, executive turnover, payment delays, and declining equity.

- Mitigation: Buffer stocks, dual sourcing, bank guarantees, and contractual audit rights.

- Tools: Third-party credit scores, automated dashboards, and AI predictive analytics.

- Action: Set automated alerts for your top 20% of suppliers by spend and criticality.

Common Questions About Supplier Financial Risk Monitoring

What is the single most important metric for supplier health?

The answer is often the equity ratio. While liquidity tells you about today, the equity ratio tells you about the supplier’s overall cushion against failure. A supplier with low equity is a house of cards waiting for a single bad quarter to collapse. If this number is consistently falling, you need to have a backup plan in place immediately.

How do I get financial data from private companies?

This is a common challenge. Unlike public companies, private firms do not have to publish their financials. The best approach is to include a “right to audit” or a financial disclosure clause in your initial contract. You can also use third party credit monitoring services that use trade payment data to estimate financial health even without a formal balance sheet.

Is a high credit score enough to prove a supplier is safe?

Not quite. A credit score is a lagging indicator based on past behavior. While a good score is positive, it does not account for sudden market shifts or internal management crises. You must combine quantitative scores with qualitative observations, such as changes in lead times or quality issues, to get the full picture of supplier viability.

Should I stop working with a supplier if their risk score drops?

Not necessarily. A drop in a supplier credit monitoring score is a reason to start a conversation, not an automatic termination. Your best move is to reach out to the supplier and ask for an explanation. They may be going through a planned restructuring or a temporary cash flow dip. Use the data as a starting point for a deeper, transparent relationship.

Final Thoughts on Staying Proactive

Managing supplier financial risk monitoring is a continuous journey, not a one time project. By focusing on the right KPIs, prioritizing your efforts through the Kraljic Matrix, and leveraging modern technology, you can protect your organization from the devastating impact of a supplier bankruptcy. The goal is to build a transparent and resilient supply chain where surprises are kept to a minimum.

Your next step is to audit your current list of strategic suppliers. Do you have their latest financial statements? Do you have automated alerts set up for their credit scores? If not, start there. Building this muscle now will ensure that when the next market disruption hits, your production lines keep moving while your competitors are left scrambling. For more information on how to integrate these checks into your broader strategy, refer to our guide on the supply chain risk management framework to see how it all fits together.