Supply Chain Risk Management: Protecting Your Operations

Is there anything more stressful than watching one small delay turn into a massive headache? If you work anywhere near operations or logistics, you know exactly what we are talking about. One day a shipment is late, and the next thing you know, your entire production line is at a standstill. It is frustrating. It is expensive. And frankly, it is enough to keep anyone up at night. That is where supply chain risk management comes in. It is not just a corporate buzzword. It is the framework that helps you see those headaches coming before they actually hit your bottom line.

We get it. The world feels more volatile than ever. Between global health crises, shifting political landscapes, and the rise of cyber threats, managing a supply chain can feel like trying to solve a puzzle while someone keeps changing the pieces. You might be feeling overwhelmed by the sheer number of things that could go wrong. The good news is that you are asking the right questions. We have spent time gathering the best insights on how to turn that uncertainty into a structured, manageable plan. This guide is designed to be your home base for everything related to keeping your operations running smoothly.

In this post, we are going to walk through the fundamentals of identifying threats and assessing their impact. We will look at the frameworks that the pros use to stay resilient. We will also explore practical strategies like diversifying your suppliers and tightening up your cybersecurity. Think of this as your ultimate resource for building a supply chain that does not just survive disruptions but actually grows stronger because of them. Let us break this down together.

What Exactly is Supply Chain Risk Management?

Let us start with the basics. Supply chain risk management, often called SCRM, is the systematic process of finding and addressing vulnerabilities across your entire network. It is about looking at the end-to-end journey of your product. This includes everything from the raw material suppliers to the final delivery to your customer. What we found is that many people think SCRM is just about logistics. In reality, it covers much more than just trucks and ships. It includes your software vendors, your manufacturers, and even your third-party service providers.

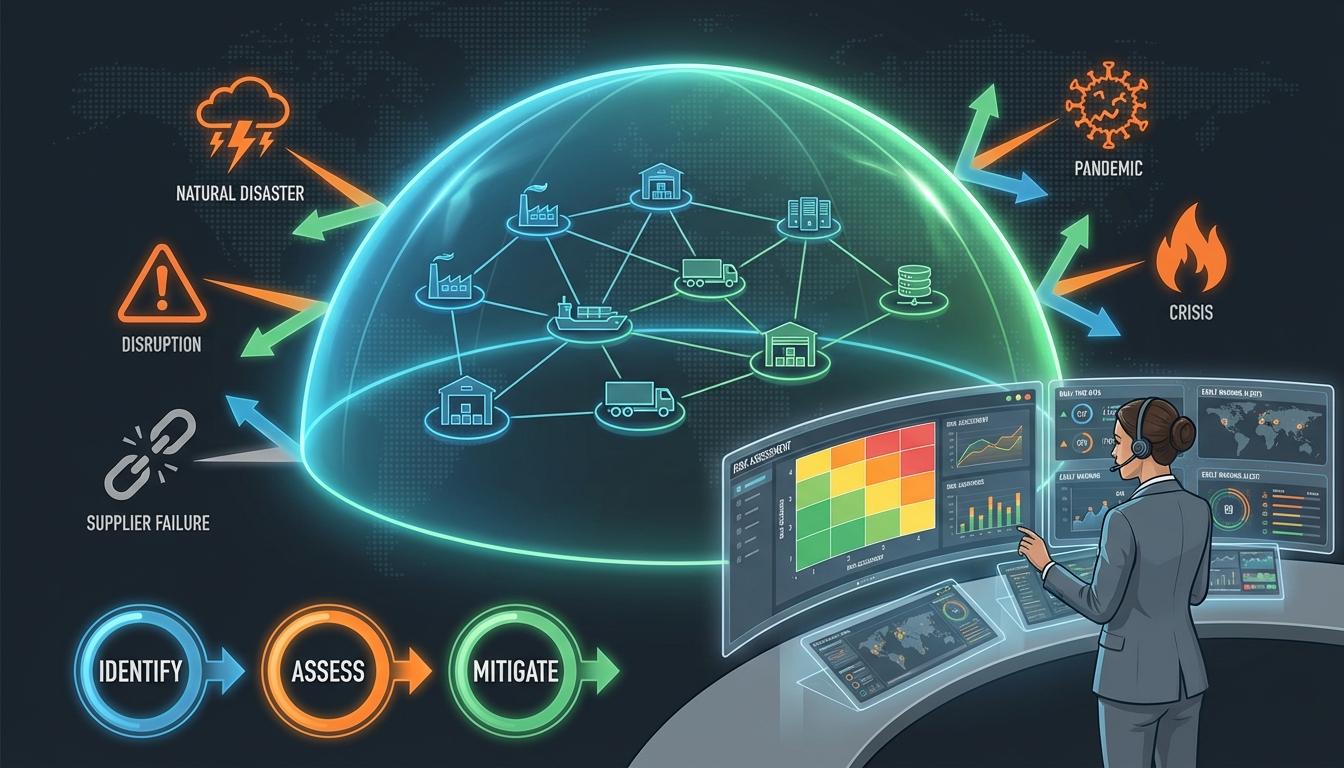

The core of this process is built on four main pillars. First, you have to identify the threats. Then, you assess how likely they are to happen and how much they would hurt if they did. After that, you create a plan to mitigate or control those risks. Finally, you monitor the situation and respond when things go sideways. It is a continuous loop. This is a journey, not a one-time project. You are building a culture of awareness that protects your reputation and your finances.

In simple terms, SCRM is about being proactive instead of reactive. Instead of waiting for a supplier to go bankrupt, you are monitoring their financial health. Instead of waiting for a port strike, you are mapping out alternative routes. This structured approach is what separates companies that thrive during a crisis from those that crumble. For a deeper look at how to visualize these connections, check out our guide on supply chain risk mapping. It is the first step in seeing the big picture.

Why Does SCRM Matter So Much Right Now?

You might be wondering if all this effort is really necessary. The short answer is yes, but there is more to it. The frequency of disruptions is rising at a staggering rate. According to the BCI Supply Chain Resilience Report 2024, nearly 80 percent of organizations experienced a significant disruption in the last year. That is a massive number. It means that disruption is no longer the exception. It is the rule. If you are not actively managing these risks, you are essentially leaving your business’s future to chance.

The drivers behind this volatility are complex. We live in a globalized world where a factory fire halfway across the globe can stop production in your local facility. Just-in-time practices, while great for efficiency, have stripped away the buffers that used to protect us. Geopolitical tensions and trade wars add another layer of uncertainty. When you add in the increasing frequency of extreme weather events, it becomes clear that the old ways of managing supply chains simply are not enough anymore.

Here is what actually matters for you. Unmanaged risk leads to more than just delays. It leads to stockouts, which mean lost sales. It leads to expedited shipping costs that eat your margins. Most importantly, it can damage your reputation. Customers today have very little patience for “supply chain issues” as an excuse for late orders. They will simply go to a competitor who was better prepared. Building a robust risk management strategy is not just about protection. It is about gaining a competitive advantage by being the most reliable player in your market.

Identifying Your Supply Chain Threats

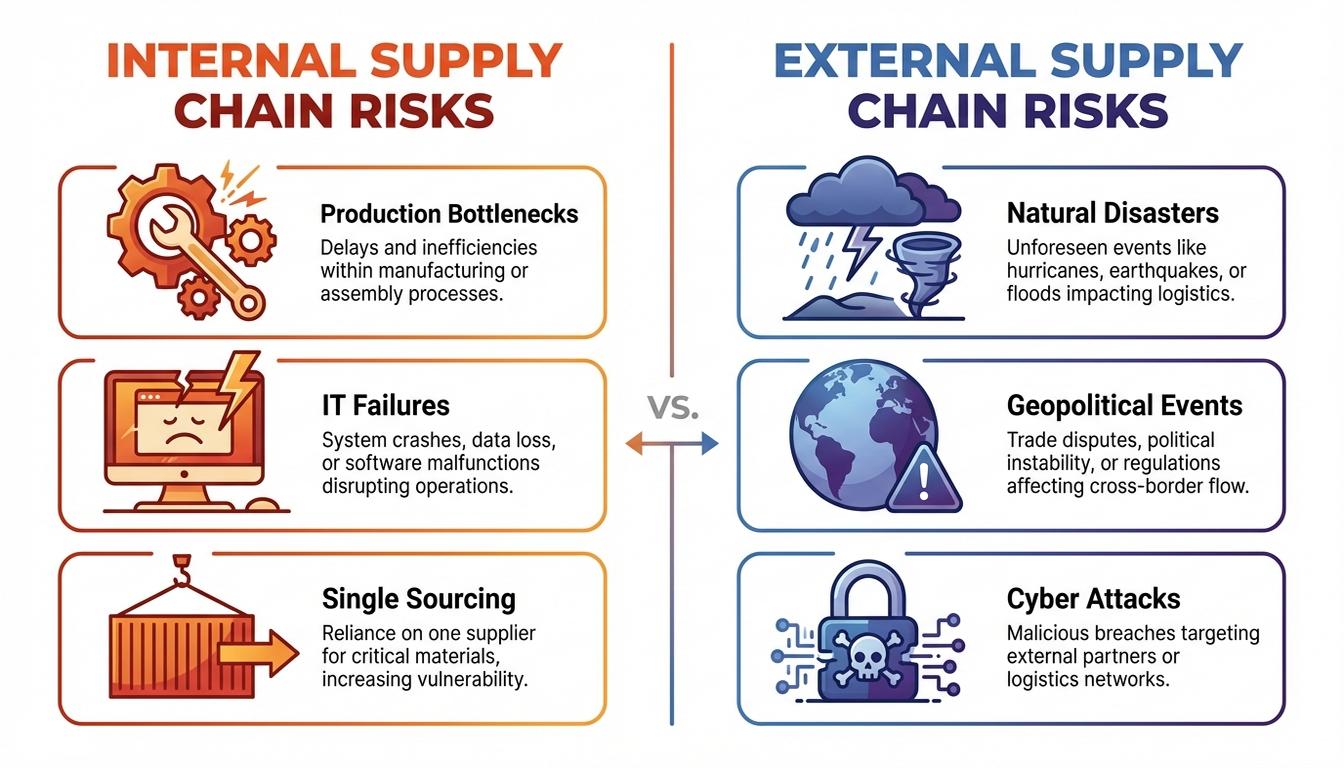

Before you can fix a problem, you have to know what it is. This is where most people get confused because the list of potential threats feels endless. To make it easier, we like to categorize risks into two main buckets: internal and external. This helps you figure out what you can control and what you need to prepare for. Let us break this down.

Internal Risks: The Calls Coming from Inside the House

Internal risks are things that happen within your own organization or your direct control. These are often the easiest to fix but the most likely to be ignored. Think about production bottlenecks. If one machine in your factory is a single point of failure, that is a risk. Forecasting errors are another huge internal threat. If your data is wrong, you might end up with too much inventory or, worse, not enough when demand peaks.

Other internal risks include things like IT system failures. If your ERP goes down, does your supply chain stop? We also see many companies struggling with single-sourcing dependencies. Relying on one supplier because they are the cheapest is a classic trap. It looks good on a spreadsheet until that supplier has a quality issue or a labor strike. These are the “hidden” vulnerabilities that you have the power to change right now.

External Risks: The World Outside Your Window

External risks are the things you cannot control but absolutely must monitor. Geopolitical events like tariffs or sanctions can change your cost structure overnight. Natural disasters are another big one. A hurricane or an earthquake can take out critical infrastructure or key suppliers. Then there are market risks, like sudden spikes in raw material prices that you cannot pass on to your customers.

One area that is getting a lot of attention lately is cyber risk. We are seeing more attacks targeting the supply chain than ever before. If a vendor you use gets hacked, your data could be at risk. This is why it is vital to look at the security of everyone you do business with. To help keep tabs on the people you rely on most, you might find our resource on supplier financial risk monitoring incredibly useful for spotting red flags early.

The SCRM Framework: A Roadmap to Resilience

Having a list of risks is a good start, but you need a structured way to handle them. This is where a risk management framework comes in. It provides a repeatable process so you aren’t reinventing the wheel every time a problem pops up. One of the most respected models in the industry is the LogicManager Risk Wheel. It simplifies the complex into five clear steps: Governance, Assessment, Mitigation, Monitoring, and Event Response.

Governance is the foundation. It is about deciding who is responsible for what. You need clear policies and roles. Assessment is the analytical part where you identify and prioritize risks. Mitigation is where you take action to reduce those risks. Monitoring is the “always-on” phase where you track performance and indicators. Finally, Event Response is your plan for when a risk actually becomes a reality. It is your crisis management playbook.

Another popular approach is the PPRR model. It stands for Prevention, Preparedness, Response, and Recovery.

- Prevention: Actions you take to stop a risk from happening in the first place, like choosing a more stable region for sourcing.

- Preparedness: Creating “what-if” plans and safety stocks so you are ready if things go wrong.

- Response: The immediate actions you take during a disruption to keep the wheels turning.

- Recovery: How you get back to normal operations and, more importantly, what you learn to improve for next time.

These frameworks work because they take the emotion out of the situation. Instead of panicking, you just follow the plan.

Conducting a Supply Chain Risk Assessment

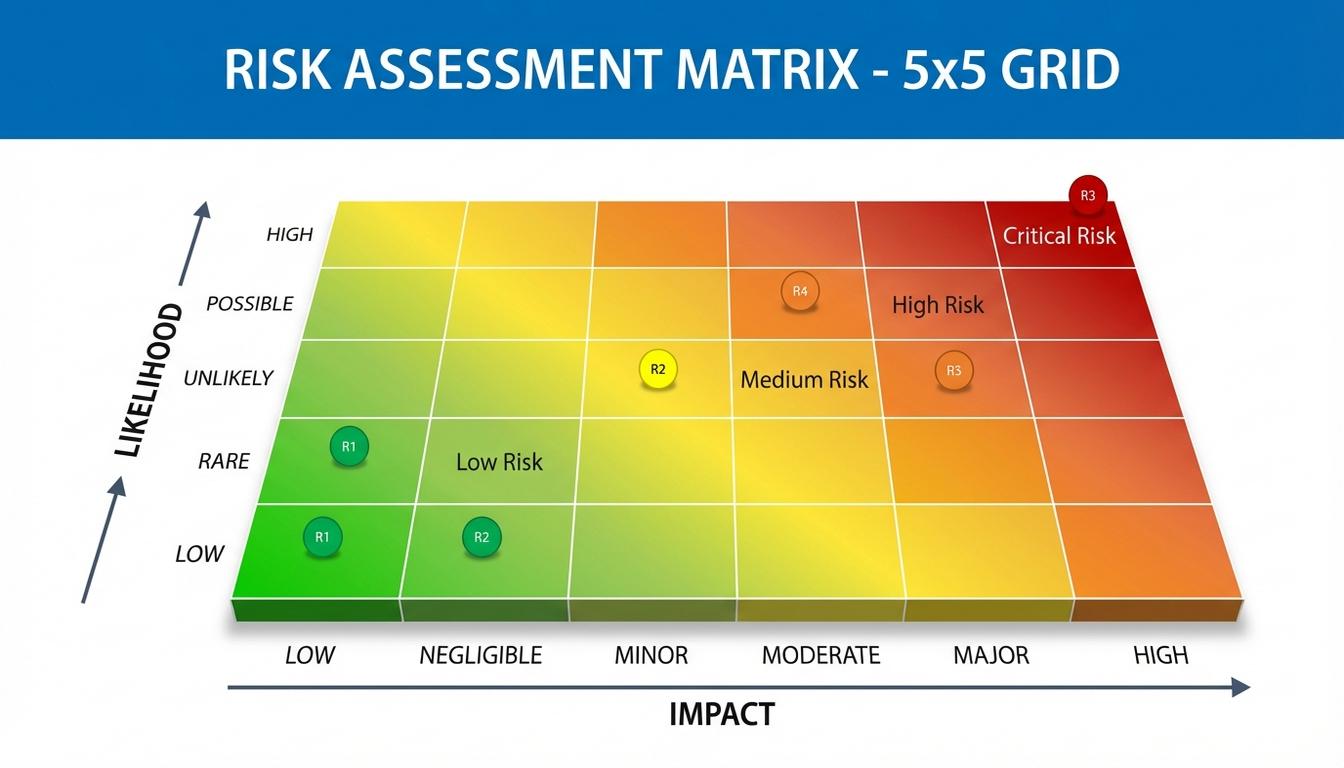

Now, you might be asking, “How do I know which risks to focus on first?” You cannot protect against everything at once. This is where a supply chain risk assessment becomes your best friend. It is a formal way to rank your vulnerabilities so you can spend your time and money where they will have the biggest impact. The most common way to do this is by looking at two factors: likelihood and impact.

Likelihood is simply how likely a risk is to occur. Impact is how much it would hurt. You can plot these on a simple 5×5 grid, often called a heat map. A risk that is highly likely and has a massive impact (like a major supplier going out of business) is your top priority. A risk that is unlikely and has a low impact (like a minor delay in office supplies) goes to the bottom of the list. It sounds simple, but you would be surprised how many companies don’t do this.

To get the best data for your assessment, you should use a variety of tools. Send out supplier questionnaires to understand their own risk plans. Conduct site audits for your most critical partners. Use process mapping to find the bottlenecks we talked about earlier. According to research from ASCM, organizations that use data-driven assessments are much more likely to recover quickly from disruptions. The goal is to move from “I think this might happen” to “Here is the data on what we need to watch.”

Proven Strategies for Risk Mitigation

Once you know where you are vulnerable, it is time to build your defenses. This is the mitigation phase. There is no one-size-fits-all solution here. The best strategy usually involves a mix of different approaches. Let us look at some of the most effective ones we have seen in action.

Diversification and Multi-Sourcing

The old saying “don’t put all your eggs in one basket” is the golden rule of SCRM. If you rely on one supplier for a critical part, you are at their mercy. Diversification means finding alternative suppliers, ideally in different geographic regions. This protects you if a specific country faces political turmoil or a natural disaster. We call this “dual sourcing” or “multi-sourcing.” It might cost a bit more to manage multiple relationships, but the peace of mind is worth every penny.

Strategic Safety Stock and Buffer Inventory

Efficiency is great, but “lean” can easily become “brittle.” One of the most practical ways to mitigate risk is to keep a strategic safety stock. This isn’t just about hoarding everything. It is about identifying the parts or products that have the longest lead times or are the hardest to replace. By keeping a buffer of these specific items, you buy yourself time to find a solution when a disruption hits. It acts as a shock absorber for your entire network.

Nearshoring and Reshoring

For a long time, the trend was to move production as far away as possible to save on labor costs. Now, many companies are doing the opposite. Nearshoring involves moving production closer to your home market. Reshoring means bringing it back entirely. This reduces the number of things that can go wrong during transport. It also makes your supply chain much more responsive to changes in demand. For more on how location impacts your safety, take a look at our analysis of geographic supply chain risk.

The Human Element: Governance and Roles

Here is something most guides do not mention. You can have the best software and the most detailed spreadsheets, but SCRM will fail if you don’t have the right people involved. Risk management is a team sport. It requires collaboration between procurement, logistics, finance, and even IT. If these departments are working in silos, risks will fall through the cracks.

A key principle in good governance is the “Separation of Duties.” In this context, it means you have different people designing the policies, performing the daily tasks, and reviewing the results. For example, your procurement team might select a vendor, but a separate risk or audit team should review that vendor’s risk profile. This creates a system of checks and balances that prevents errors and reduces the chance of fraud. It ensures that someone is always looking at the big picture while others focus on the details.

You also need clear ownership. Who is the person everyone looks to when a ship gets stuck in the canal? If the answer is “we aren’t sure,” you have a governance problem. Successful companies often have a dedicated risk management team that oversees the framework, while the individual departments are responsible for executing the mitigation strategies. This clarity of role is what allows for a fast, coordinated response during a crisis.

Integrating ESG and Cybersecurity into SCRM

The world of risk is expanding. It is no longer enough to just worry about whether a part arrives on time. You also have to worry about *how* that part was made and how the data surrounding it is handled. This is where Environmental, Social, and Governance (ESG) criteria and cybersecurity come into play. They are now core parts of any modern supply risk strategy.

ESG risk is about your reputation and legal compliance. If a supplier three tiers down your chain is found to be using unethical labor or dumping chemicals into a river, your brand is the one that will take the hit. Many countries are passing laws that require companies to do due diligence on their entire supply chain. According to experts at EcoVadis, monitoring these factors is now essential for long-term viability. It is about making sure your supply chain is as sustainable as it is efficient.

Cybersecurity is the other major frontier. Every time you connect your systems with a vendor, you create a potential doorway for hackers. A breach at a small logistics provider can lead to a massive data leak at a Fortune 500 company. This is why you must require your partners to meet specific security standards. It is not just an IT problem. It is a supply chain problem. If your suppliers aren’t secure, you aren’t secure. It is that simple.

Building a Resilient Culture

At the end of the day, SCRM is about building resilience. Resilience is the ability to bounce back. It is about being flexible enough to pivot when the original plan falls apart. This requires a shift in mindset. Instead of trying to create a “perfect” plan that will never fail, you create a system that is designed to handle failure. You expect the unexpected.

One way to build this culture is through scenario planning. Sit your team down and ask, “What if our main port closes for a month?” or “What if our top supplier has a cyberattack?” Walking through these scenarios helps you find the gaps in your plan before they matter. It builds “muscle memory” so that when a real crisis hits, your team knows exactly what to do. The goal is to be the company that stays calm because they have already played this game in their heads a dozen times.

Continuous monitoring is the other half of the resilience equation. The world changes fast. A supplier that was healthy six months ago might be struggling today. A region that was stable might suddenly be in turmoil. You need tools and processes that give you real-time visibility. As highlighted by IBM, using advanced analytics and dashboards can help you spot these trends before they become full-blown disasters. Resilience is not a destination. It is a way of operating.

Frequently Asked Questions

What is the difference between risk management and resilience?

Great question. Think of risk management as the process of identifying and minimizing potential problems. Resilience is the outcome of that process. It is your ability to stay operational and recover quickly when a problem actually occurs. Risk management is the “how,” and resilience is the “result.” You need the first to achieve the second.

How deep should I go into my supply chain?

This comes up a lot, and the answer is: deeper than you think. Most companies only monitor their Tier-1 suppliers, the ones they buy from directly. However, many major risks hide in Tier-2 or Tier-3. If all your Tier-1 suppliers buy their raw materials from the same single source, you have a major vulnerability you don’t even know about. Try to map your most critical components as far back as possible.

Is SCRM only for big corporations?

Not at all. In fact, small businesses are often more vulnerable to supply chain shocks because they have fewer resources to fall back on. While a giant corporation might survive a $1 million loss, that same loss could bankrupt a smaller company. The scale of your plan will be different, but the principles of identifying and mitigating risk are the same for everyone.

How often should we update our risk assessment?

At a minimum, you should do a full review once a year. However, you should also trigger a review whenever there is a major change, such as onboarding a new critical supplier, entering a new market, or a major geopolitical shift. Ideally, you want a system of continuous monitoring so you are always seeing new data as it comes in.

What is the most common mistake companies make in SCRM?

The biggest mistake is treating it like a “check the box” compliance exercise. If you just fill out the forms and then put them in a drawer, you aren’t actually managing risk. You have to use the information to make real decisions, like changing suppliers or increasing inventory levels. SCRM has to be integrated into your daily operations to be effective.

Wrapping Up Your Risk Strategy

We have covered a lot of ground together. From the basic definitions to the deep dives into ESG and cybersecurity, the world of supply chain risk management is definitely complex. But if there is one thing we want you to take away, it is this: you don’t have to be perfect to be protected. The most important step is simply starting. By moving from a reactive mindset to a proactive one, you are already ahead of most of your competition.

Remember to keep things simple at first. Map your critical paths. Identify your biggest “what-ifs.” Start building those relationships with your suppliers that are based on transparency and shared risk. Over time, you can add the fancy analytics and the complex frameworks. For now, focus on the fundamentals of visibility and diversification. It is about protecting your hard work and making sure that when the next storm hits, your business is the one with the strongest foundation.

So, what is the next step for you? Maybe it is a conversation with your procurement lead. Maybe it is a quick audit of your top five suppliers. Whatever it is, take that step today. You have the tools and the knowledge to build a more resilient future for your operations. You have got this. If you ever feel overwhelmed, just come back here and walk through the steps again. We are all learning how to navigate this new world together.